High-precision stamping die limiting structure capable of preventing materials from deviating

A stamping die and limit structure technology, applied in the field of stamping dies, can solve the problems of stamping parts offset, stamping parts damage, slowness, etc., and achieve the effect of avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

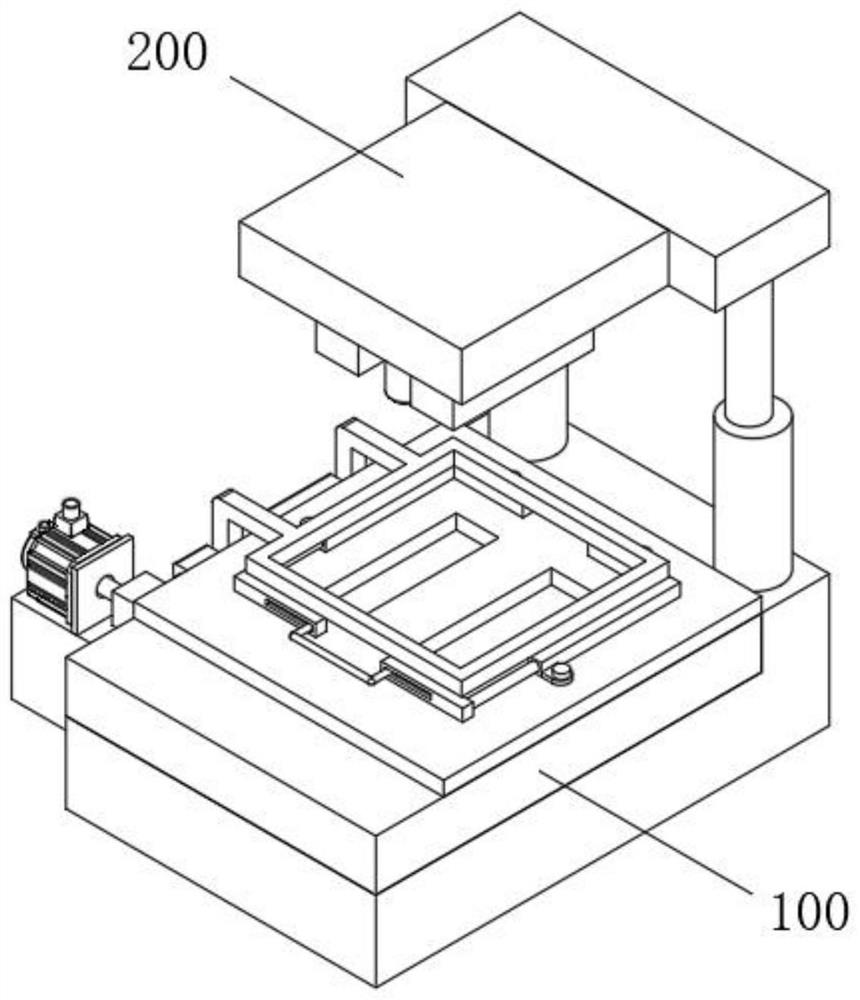

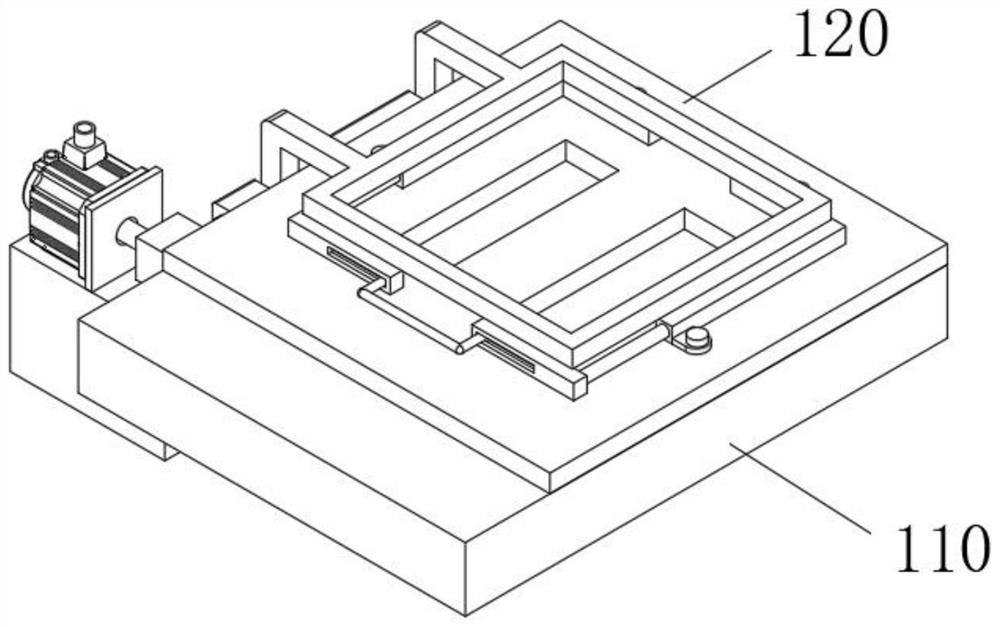

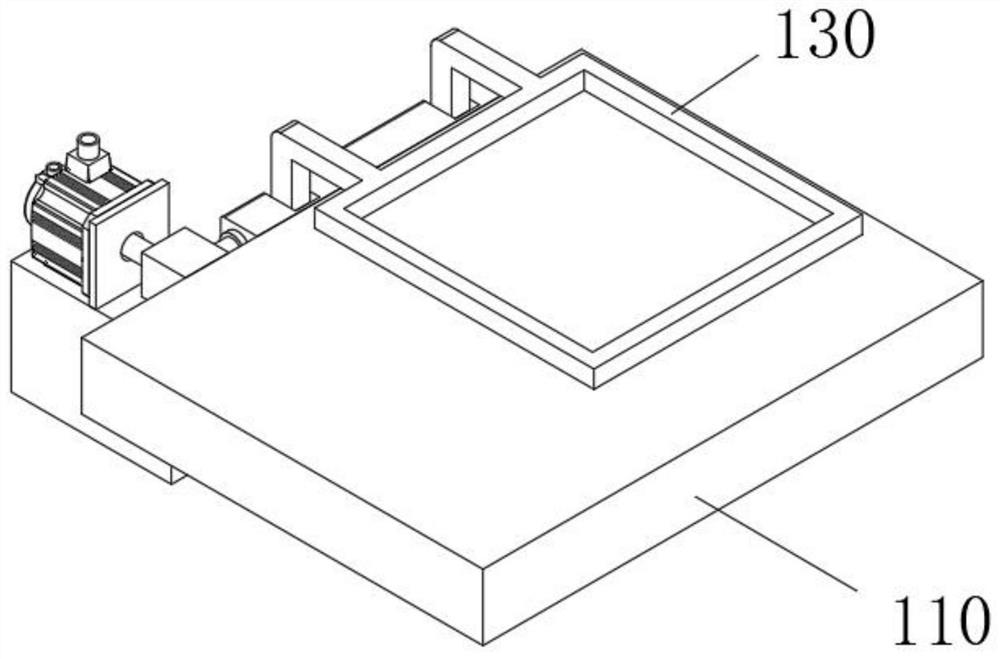

[0062] see Figure 1-Figure 15 As shown, this embodiment provides a high-precision stamping die limit structure for preventing material offset, including a stamping device 200 and a limit mechanism 100 installed inside the stamping device 200. The limit mechanism 100 includes at least:

[0063] Mounting seat 110, the mounting seat 110 is a rectangular plate structure, which is convenient for the installation of various parts on the limit mechanism 100, and plays a supporting role;

[0064] The limit device 120, the limit device 120 includes a movable plate 121, the upper surface of the movable plate 121 is provided with a stamping groove 1210, which is convenient for the deformation and separation of the stamping parts, the movable plate 121 is fixedly connected with the mounting seat 110 by bolts, To facilitate the installation of the limiter 120, the top of the movable plate 121 is connected with a clamping device 122, and there are two clamping devices 122, and the two clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com