Automatic punching machine special for rice cooker inner container

A rice cooker, punching machine technology, applied in applications, household appliances, other household appliances, etc., can solve the problems of slow material loading and unloading, inconvenient movement, etc. slow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

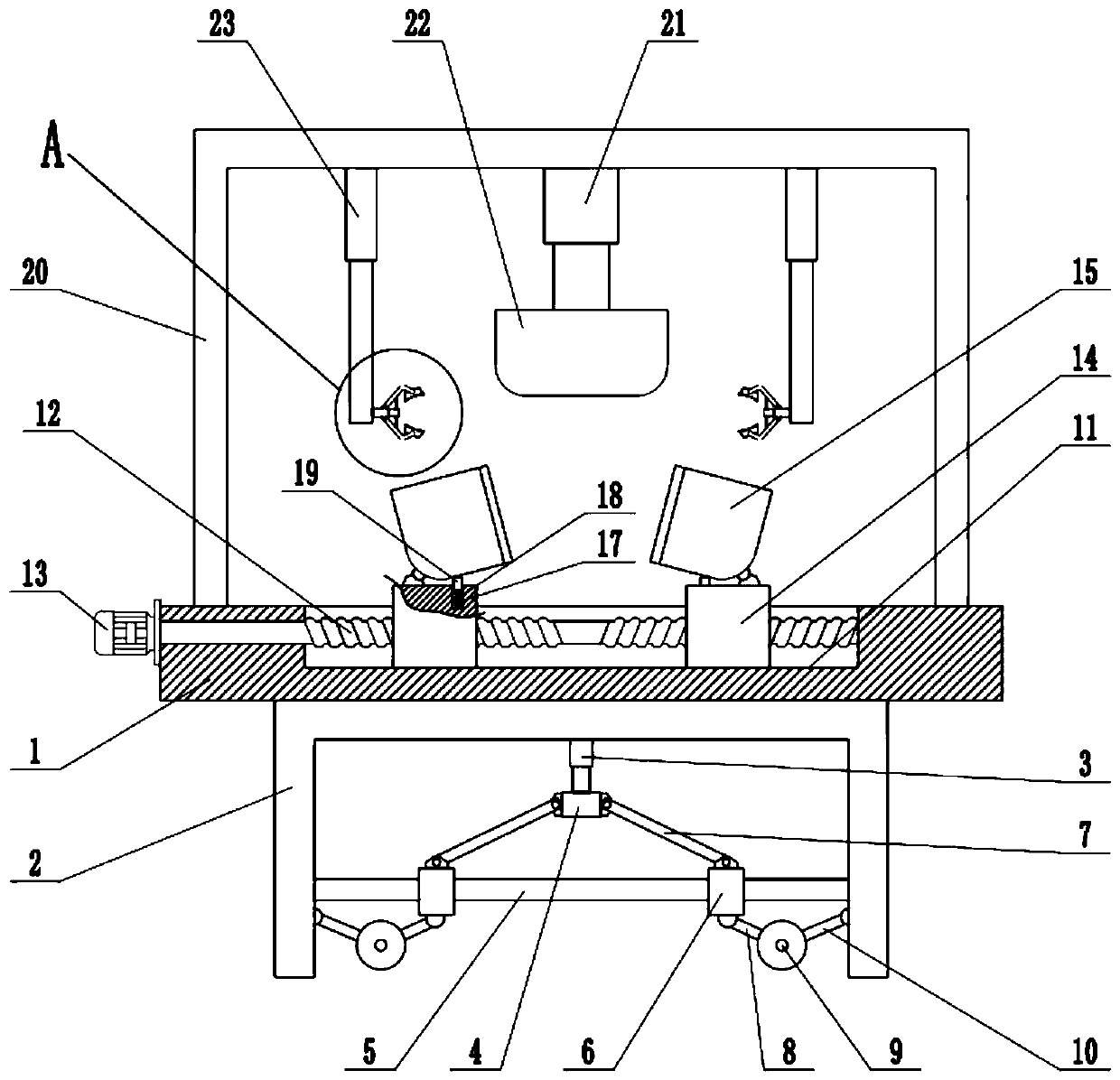

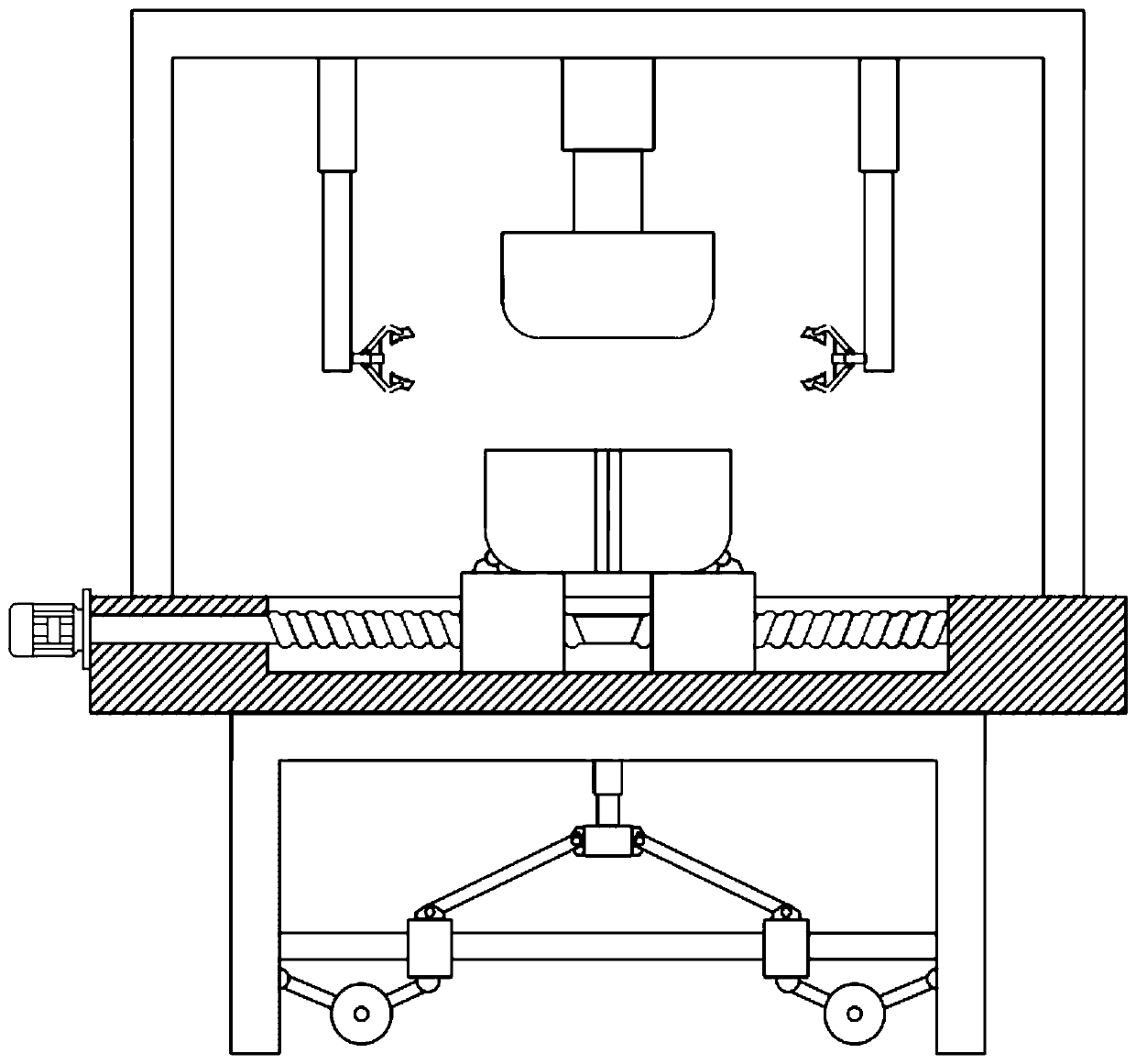

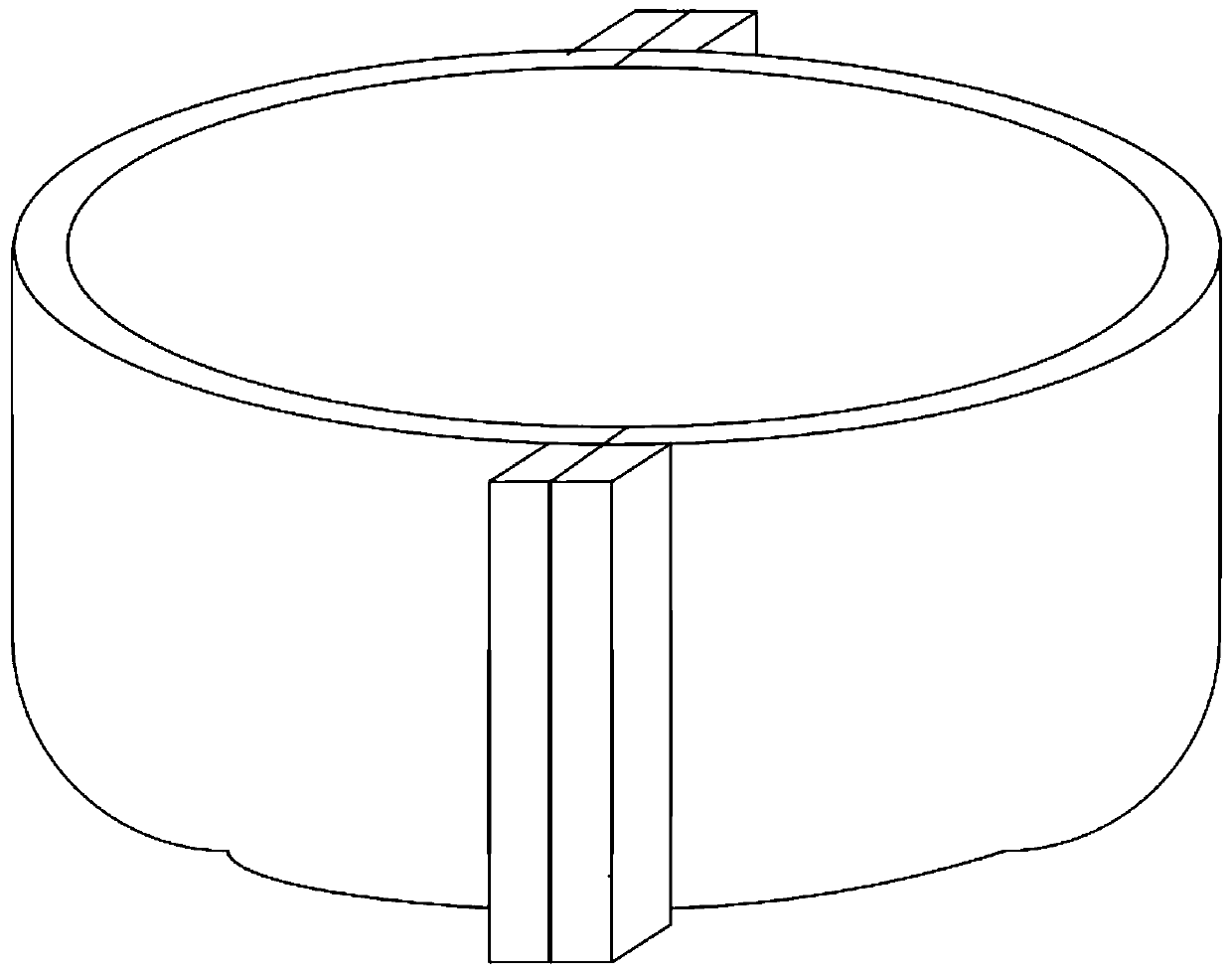

Embodiment 1

[0023] see Figure 1-6 , in the embodiment of the present invention, a kind of special automatic stamping machine for electric rice cooker liner, comprises workbench 1, lower die 15, fixed frame 20, second telescoping mechanism 21 and upper die 22, and the upper surface of workbench 1 is provided with Chute 11, the inside of chute 11 is equipped with two-way screw mandrel 12, the left and right ends of two-way screw mandrel 12 are respectively connected with the side wall rotation of chute 11, and the outer side wall of workbench 1 is fixedly connected with regulating motor 13, and regulating motor The shaft extension end of 13 is connected with two-way screw mandrel 12, and adjusting motor 13 is a forward and reverse motor, and two-way screw mandrel 12 is set with support block 14, and support block 14 is threadedly connected with two-way screw mandrel 12, and support block 14 has two Two, left and right symmetrically arranged, the lower mold 15 is hinged on the support block...

Embodiment 2

[0025] On the basis of Embodiment 1, a moving mechanism is installed on the lower surface of the workbench 1, and the moving mechanism includes a support 2, a support 2, a lifting block 4, a guide rod 5, a slider 6, a first connecting rod 7, and a second connecting rod. 8. The roller 9 and the third connecting rod 10, the lower surface of the workbench 1 is fixedly connected with the support 2, the top of the support 2 is fixedly connected with the first telescopic mechanism 3, the first telescopic mechanism 3 is an electro-hydraulic telescopic cylinder, the first The lower end of telescoping mechanism 3 is fixedly connected with lifting block 4, and the bottom of lifting block 4 is provided with guide bar 5, and the left and right ends of guide bar 5 are fixedly connected with support 2 respectively, and guide bar 5 is sleeved with slide block 6, and slide block 6 is slidably connected with the guide rod 5. There are two sliders 6, which are symmetrically arranged left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com