Double-stroke pressing device applied to workpiece machining

A pressing device and double-stroke technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high concentration, easy fatigue, work area touching the workpiece, and high requirements for operators, so as to achieve post-maintenance Easy to maintain, easy to move, and flexible to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

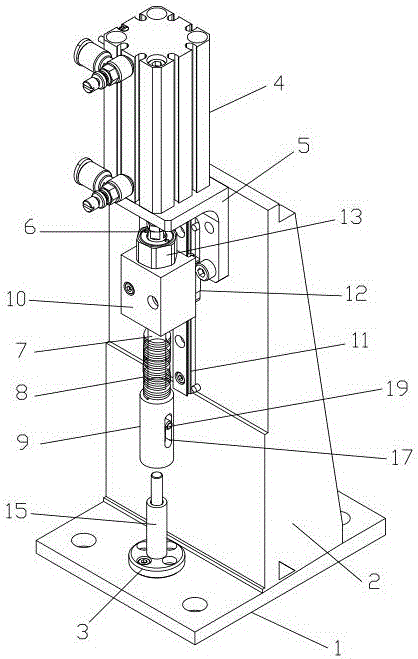

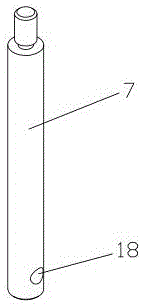

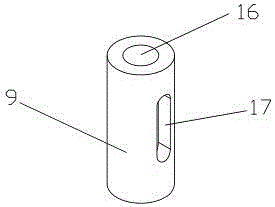

[0024] Such as Figure 1 to Figure 4 As shown in the figure, a double-stroke pressing device applied to workpiece processing includes a base plate 1, a bracket 2 and a workbench 3. Both the bracket 2 and the workbench 3 are fixedly installed on the base plate 1, and the workbench 3 is located on the front side of the base plate 1. , the bracket 2 is located on the rear side of the base plate 1, and the bracket 2 is provided with a double-stroke pressing mechanism, the double-stroke pressing mechanism includes a cylinder driving assembly and a pressing assembly, and the cylinder driving assembly includes a driving cylinder 4, a cylinder mounting seat 5 and a piston rod 6. The cylinder mounting seat 5 is fixedly installed on the top of the bracket 2, the cylinder mounting seat 5 is provided with a drive cylinder 4, the drive cylinder 4 is connected to the piston rod 6, and the piston rod 6 is connected to a compression assembly, which includes a compression shaft 7, Compression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com