Vertical bamboo board cylinder forming machine

A molding machine and bamboo board technology, which is applied in mechanical equipment, sugarcane machining, manufacturing tools, etc. It can solve the problems that the quality of bamboo tube products cannot be guaranteed, the bamboo tube is easy to crack, and the adhesion between bamboo board and mandrel is poor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

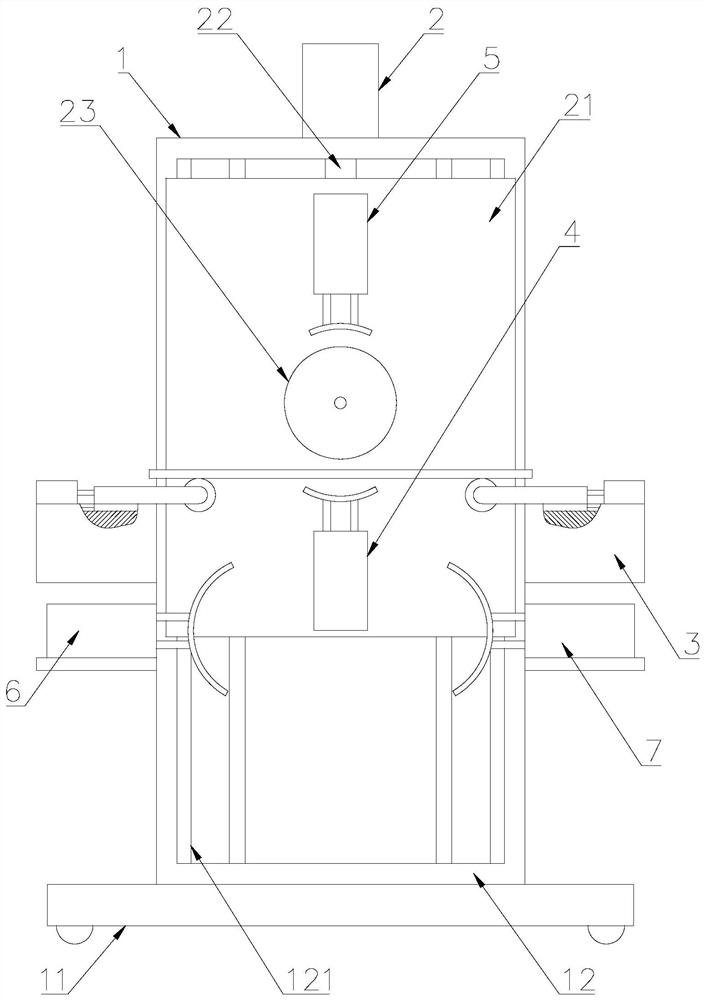

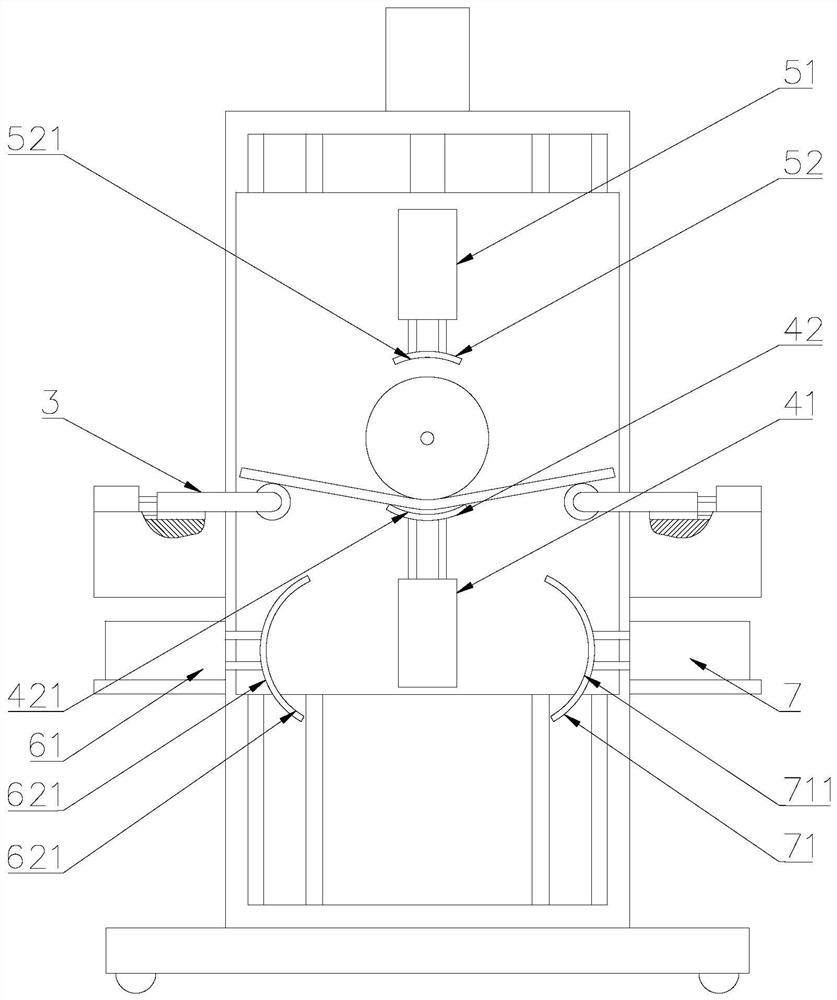

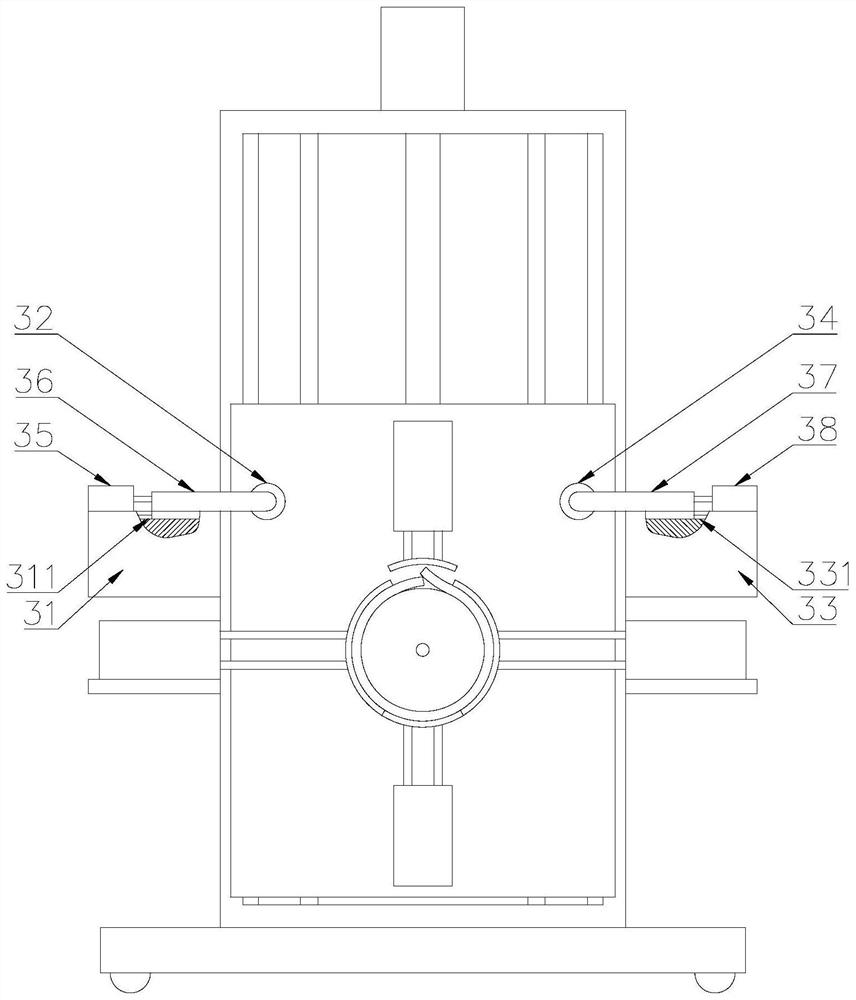

[0054] Please refer to Figure 1 to Figure 3 As shown, the first embodiment of the present invention is: a vertical bamboo board cylinder forming machine, including a frame 1 and a lifting adjustment mechanism 2, a support mechanism 3, and a first forming assembly respectively arranged on the frame 1 4. The second molding component 5, the third molding component 6 and the fourth molding component 7;

[0055] The frame 1 includes a base 11 and a main shaft 12, the main shaft 12 is set up vertically on the top surface of the base 11, and the main shaft 12 is provided with a guide rail 121 along the vertical direction;

[0056] The lifting adjustment mechanism 2 includes a lifting frame 21, a lifting oil cylinder 22 and a heating die head 23. The lifting frame 21 is provided with a chute slidingly matched with the guide rail 121, and the cross-sectional shapes of the guide rail 121 and the chute are both T-shaped, the lifting cylinder 22 is arranged on the main shaft 12, the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com