Stamping die

A technology of stamping dies and templates, which is applied in the field of molds, can solve the problems of inconvenient stamping die product forming, increased unqualified rate of molded products, and larger errors, so as to achieve the effects of improving the qualified rate, ensuring accuracy and stability, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

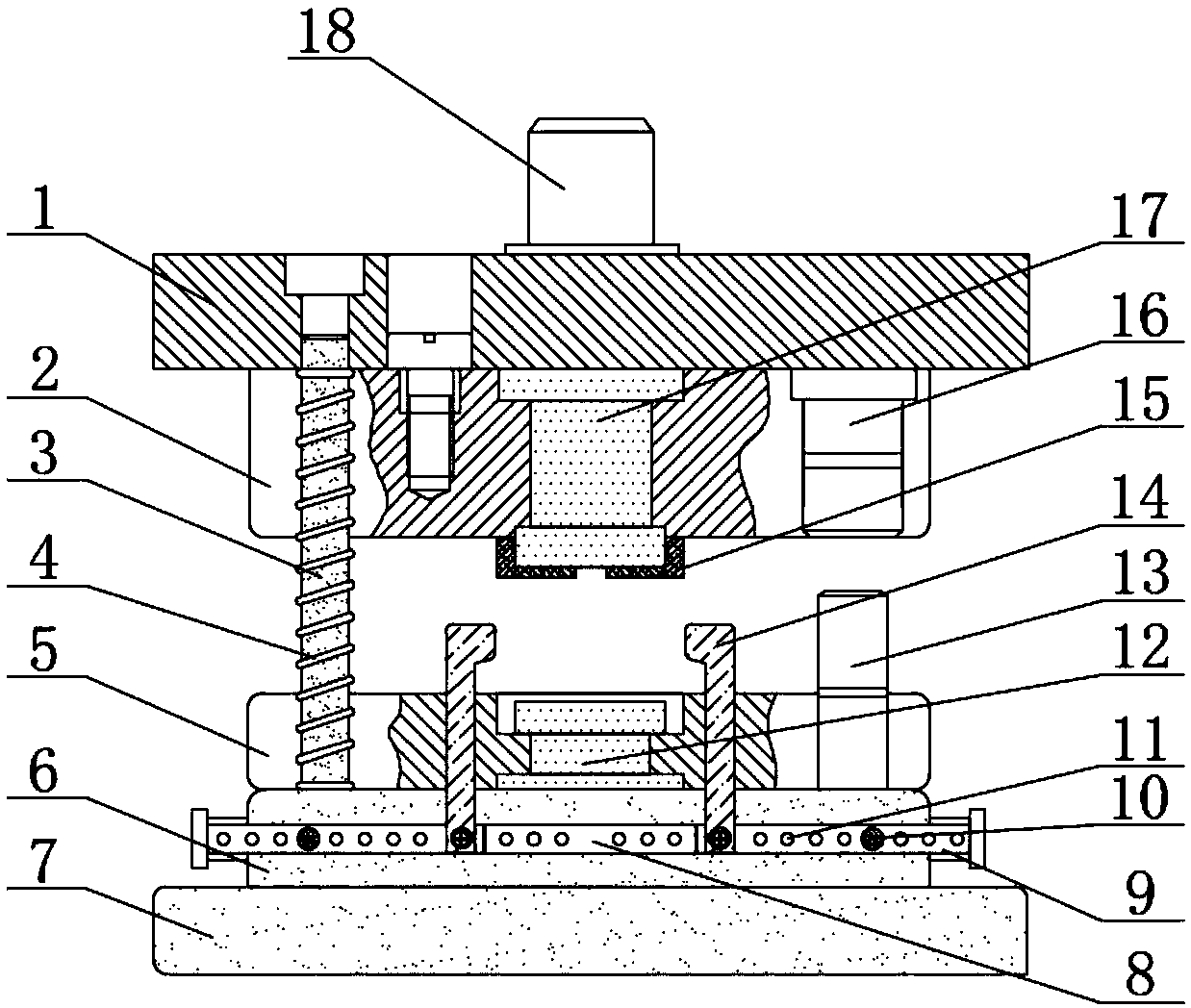

[0019] Embodiment 1: A kind of stamping mold, comprises lower template 7, fixed mold fixed plate 6, fixed mold core 12, upper template 1, pressure plate 2 and movable mold core 17, and described fixed mold fixed plate 6 is fixedly installed on lower template 7 The upper surface of the upper surface of the fixed mold fixed plate 6 is fixedly installed with a stripping plate 5 at the middle position of the upper surface of the fixed mold fixed plate 6. Installed on the lower surface of the upper template 1, a movable mold core 17 is fixedly installed inside the cavity opened at the middle position of the pressure plate 2, and a mold handle 18 is fixedly installed at the middle position of the upper surface of the upper template 1;

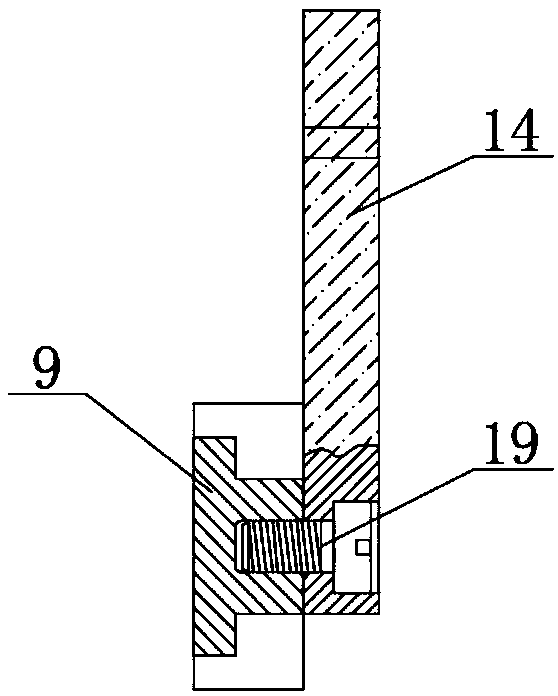

[0020] The front surface of the fixed mold fixed plate 6 is provided with a chute 8, the inside of the chute 8 is equipped with a slide bar 9, and the outer surface of the slide bar 9 is fixedly installed on the side close to the inside of the chute 8...

Embodiment 2

[0024] Embodiment 2: a stamping die, comprising a lower template 7, a fixed mold fixed plate 6, a fixed mold core 12, an upper template 1, a pressing plate 2 and a movable mold core 17, and the fixed mold fixed plate 6 is fixedly installed on the lower template 7 The upper surface of the upper surface of the fixed mold fixed plate 6 is fixedly installed with a stripping plate 5 at the middle position of the upper surface of the fixed mold fixed plate 6. Installed on the lower surface of the upper template 1, a movable mold core 17 is fixedly installed inside the cavity opened at the middle position of the pressure plate 2, and a mold handle 18 is fixedly installed at the middle position of the upper surface of the upper template 1;

[0025] The front surface of the fixed mold fixed plate 6 is provided with a chute 8, the inside of the chute 8 is equipped with a slide bar 9, and the outer surface of the slide bar 9 is fixedly installed on the side close to the inside of the chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com