Automatic discharging method

An automatic nesting and algorithm technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, complex calculation, and difficulty in achieving high plate utilization, and achieve improved automatic nesting The effect of material efficiency and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

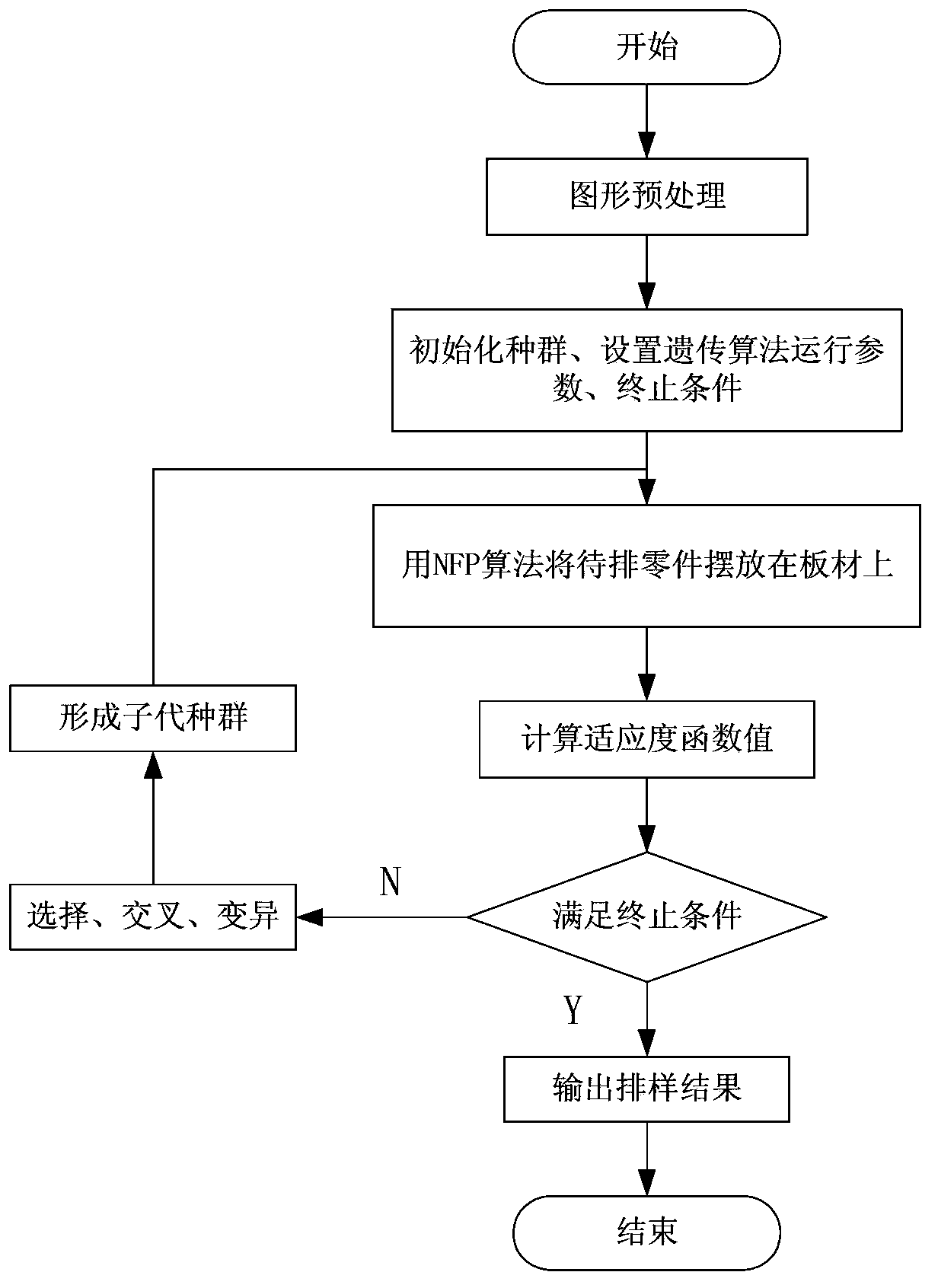

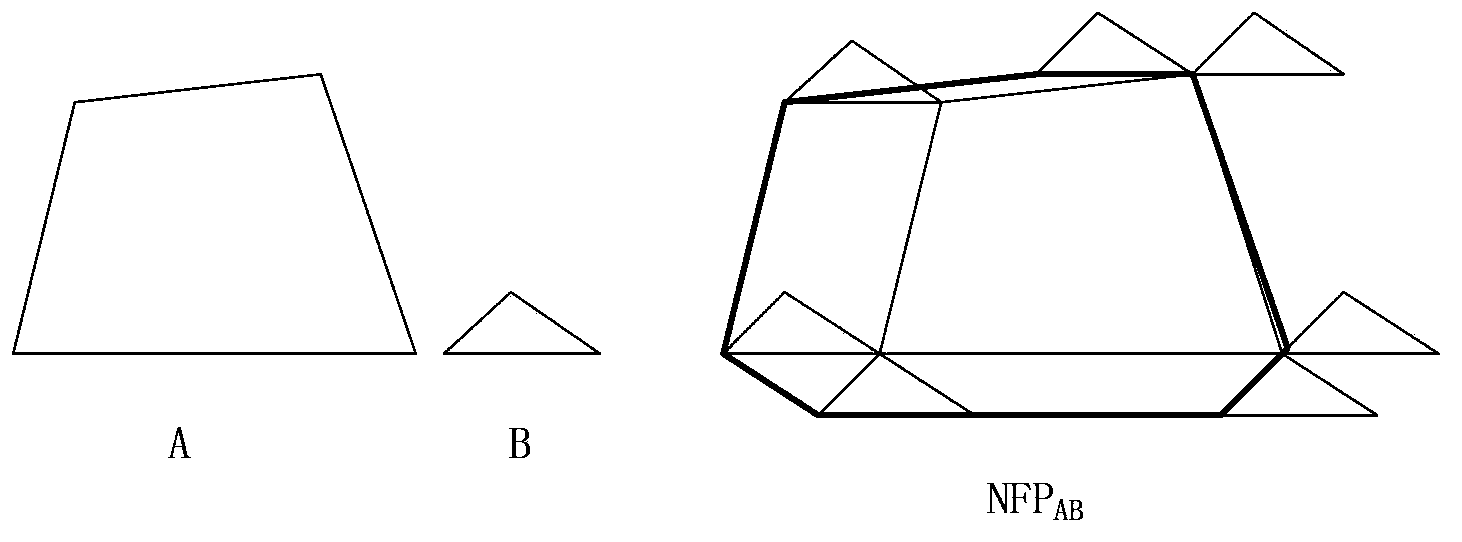

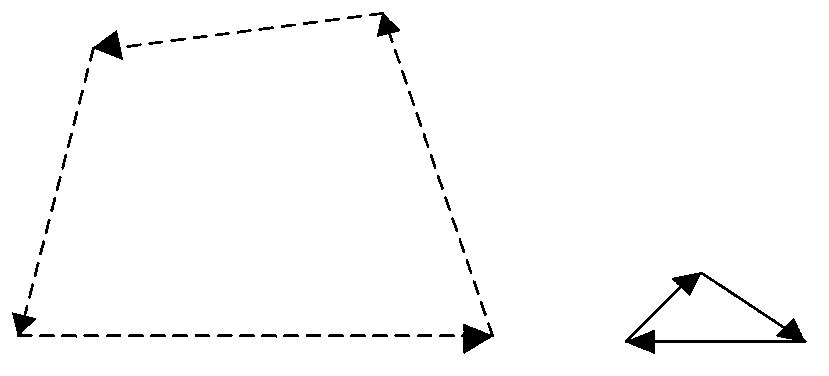

[0025] The automatic discharge method of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0026] Genetic Algorithm (Genetic Algorithm) is a kind of randomized search method evolved from the evolution law of the biological world (survival of the fittest, genetic mechanism of survival of the fittest). The genetic algorithm starts from a population that represents the potential solution set of the problem, and a population is composed of a certain number of individuals encoded by genes. Each individual is actually an entity with chromosomes. After the generation of the first generation group, according to the principle of survival of the fittest and survival of the fittest, generation by generation (generation) evolution produces better and better approximate solutions. In each generation, selection is made according to the fitness of individuals in the problem domain. Individuals, and with the help o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com