Mixing-type mineral flotation machine

A flotation machine and hybrid technology, which is applied in the field of flotation machines, can solve the problems of increasing labor, affecting work efficiency, and large consumption of chemicals, so as to increase the amount of foaming in flotation, improve beneficiation efficiency, and reduce labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention, without limiting their rights.

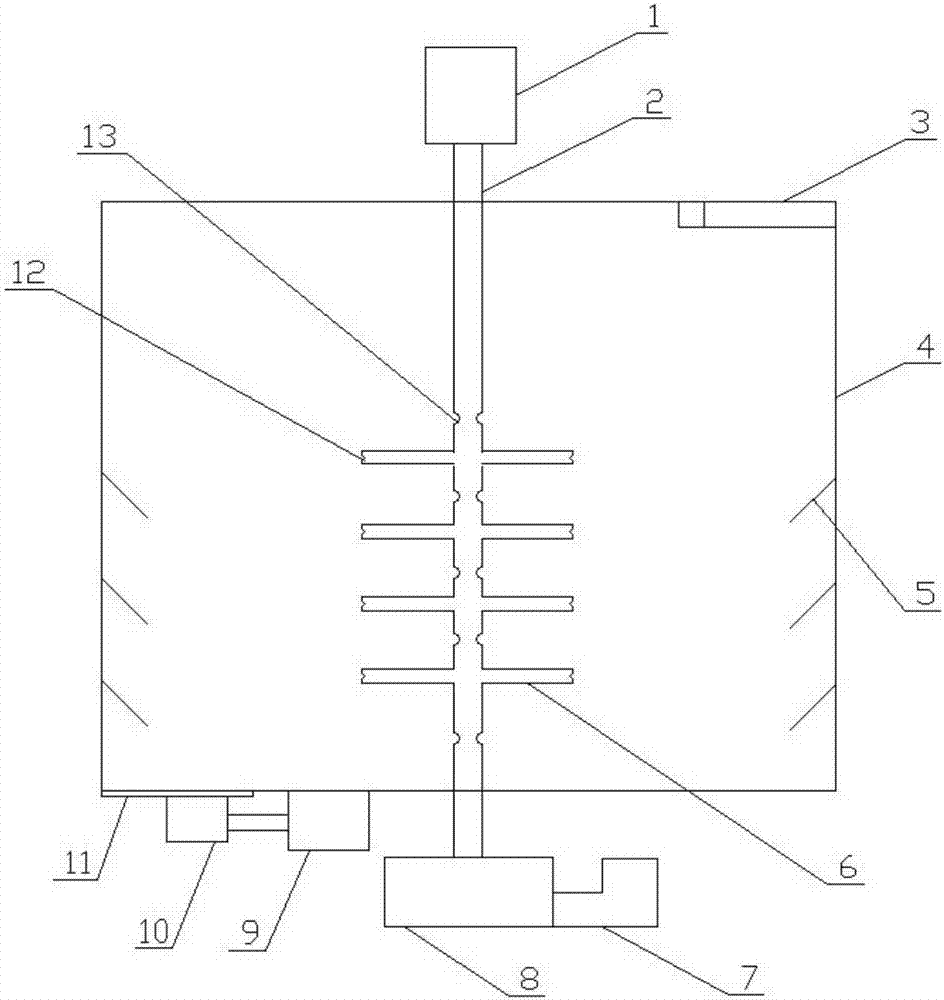

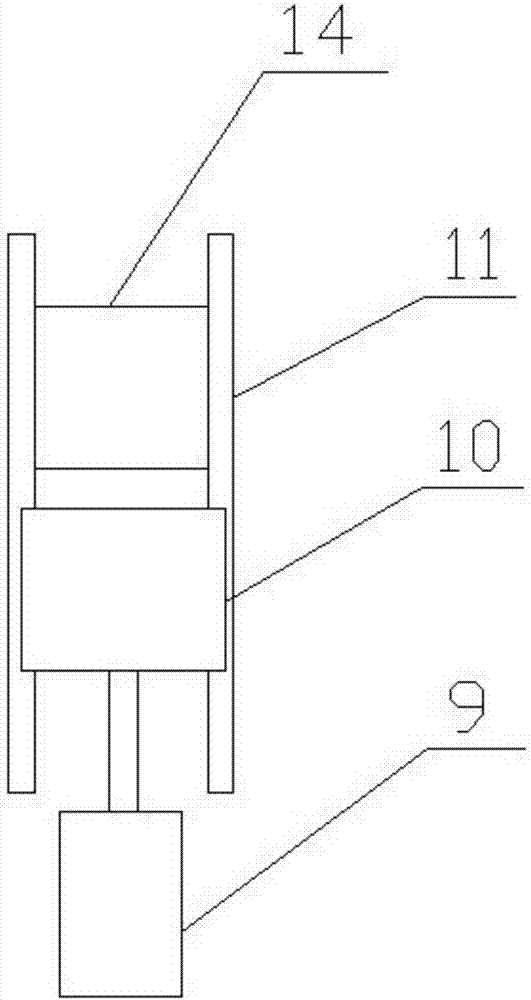

[0018] refer to Figure 1-2 , a hybrid mineral flotation machine, the flotation machine includes a flotation box 4 and a hollow central shaft 2, the top of the flotation box 4 is provided with a feed port, the bottom is provided with a discharge port, and the central shaft 2 runs through the flotation box 4 from top to bottom, and is installed on the flotation box 4 through bearings and bearing housings; the upper end of the central shaft 2 is closed and connected to the drive motor 1, and the lower end is connected to the inflation device; A stirring tube 6 communicating with the central shaft 2 is fixedly installed on the central shaft 2 , and a plurality of air outlet holes 12 are arranged on the stirring tube 6 . The feed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com