Waste glass crushing mechanism

A pulverizing mechanism and waste glass technology, applied in the removal of smoke, cocoa, grain processing, etc., can solve the problems of mixing glass dust and glass particles, poor blade pulverization effect, affecting recycling, etc., to reduce the difficulty of recycling and increase the effect. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

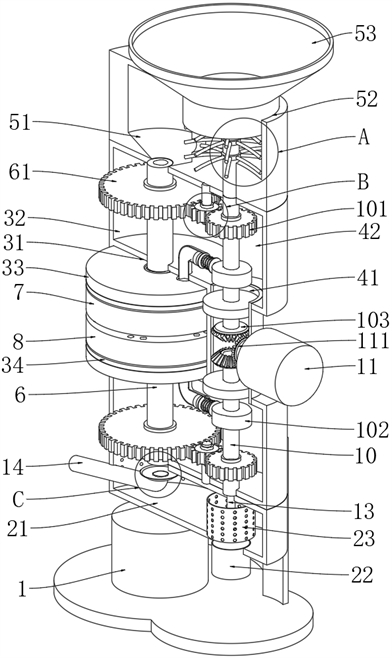

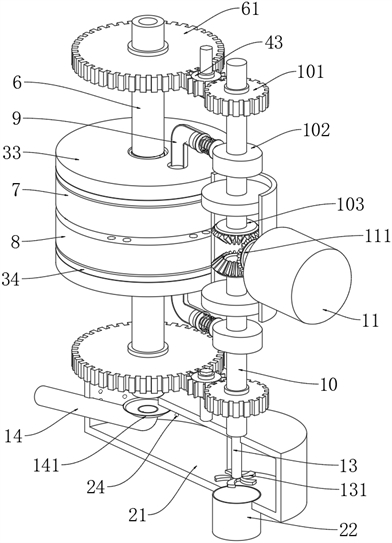

[0023] refer to figure 1 and figure 2 , a waste glass crushing mechanism, comprising a base 1, a separation box 2 is installed above the base 1, a crushing box 3 and a power box 4 are respectively installed above the separation box 2, and a crushing box 3 and a power box 4 are installed together above The crushing box 5, the crushing box 3 includes a crushing chamber 31 arranged in the middle, and two feeding pipes 6 are inserted symmetrically in the crushing chamber 31, and each feeding pipe 6 is slidingly inserted with an extruding pipe 62, The upper millstone 7 and the lower millstone 8 are respectively installed on the two extruding tubes 62, through the friction and extrusion between the upper millstone 7 and the lower millstone 8, the primary broken glass can be crushed to increase the degree of crushing and facilitate recycling;

[0024] refer to Figure 4 and Figure 8 The upper and lower inner walls of the crushing chamber 31 are symmetrically equipped with two an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com