Fabric surface pilling removal equipment

A fabric and equipment technology, applied in the field of fabric surface ball removal equipment, can solve the problems that affect the practicality of the device, easy to accumulate in the device, residual waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

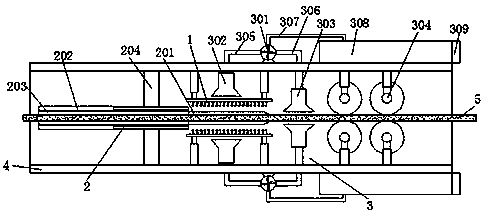

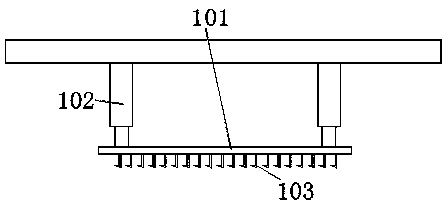

[0020] As shown in the figure, a device for removing balls on the surface of fabrics includes a frame and two groups of ball removing mechanisms.

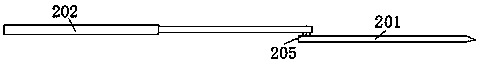

[0021] The ball removing mechanism includes a ball scraping device, a shearing device, and a dust removal device. The ball scraping device includes a scraper and two first electric push rods, and the two first electric push rods are respectively arranged on the frame. The free telescopic end of the electric push rod is respectively connected with the scraper, and the scraper is provided with a number of uniformly distributed scraper hooks; the shearing device includes a shear blade, a second electric push rod and a mounting plate, and the shear The blade is movably arranged in the mounting plate, the mounting plate is connected with the frame through the connecting plate, the second electric push ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com