Wear-resistant lining plate for large self-grinding machine / large semi-self-grinding machine

A semi-autogenous mill and wear-resistant liner technology, which is applied in grain processing and other fields, can solve the problems of low liner life at the feed end, narrow discharge channel, and low discharge efficiency of the mill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

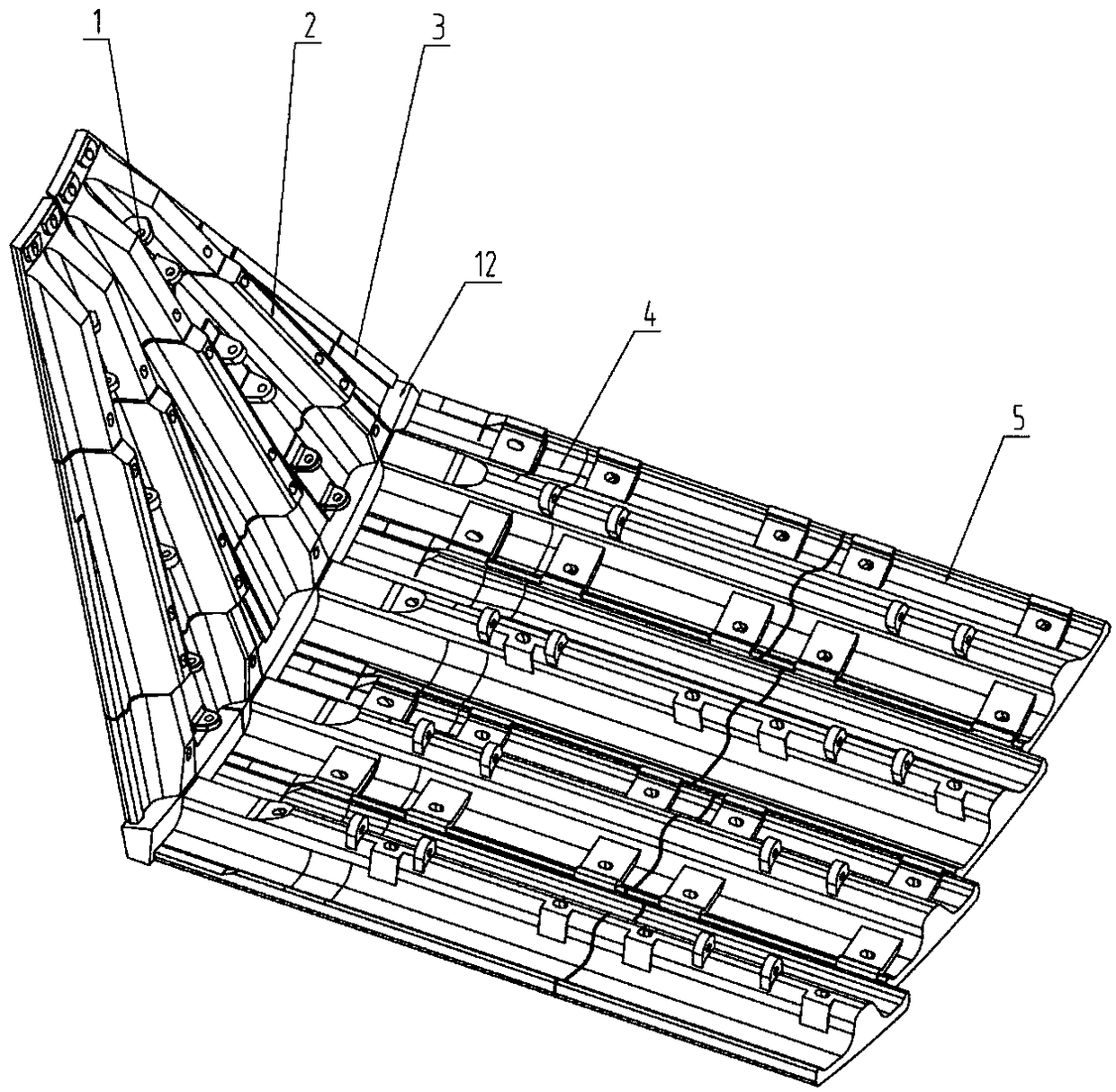

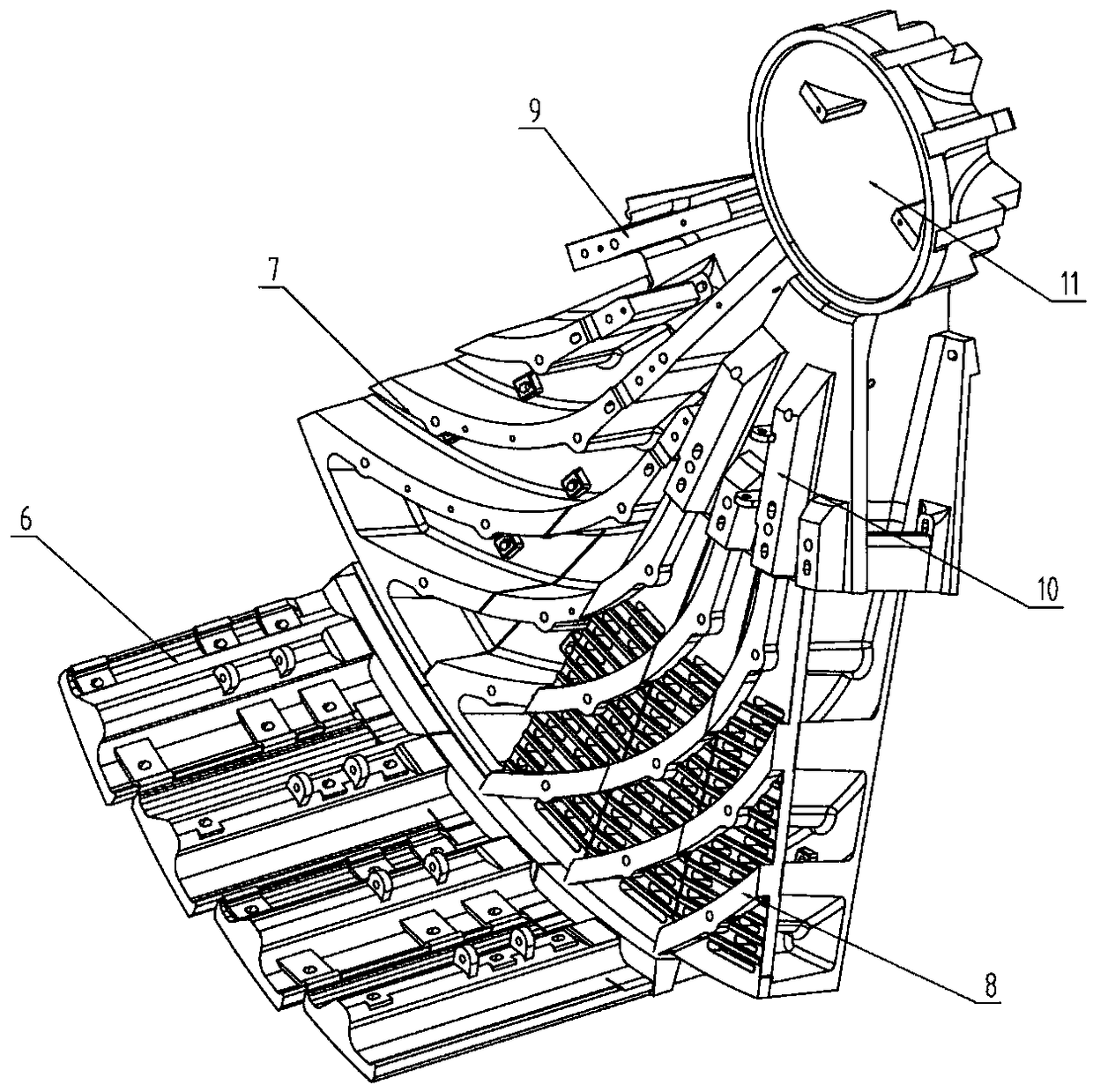

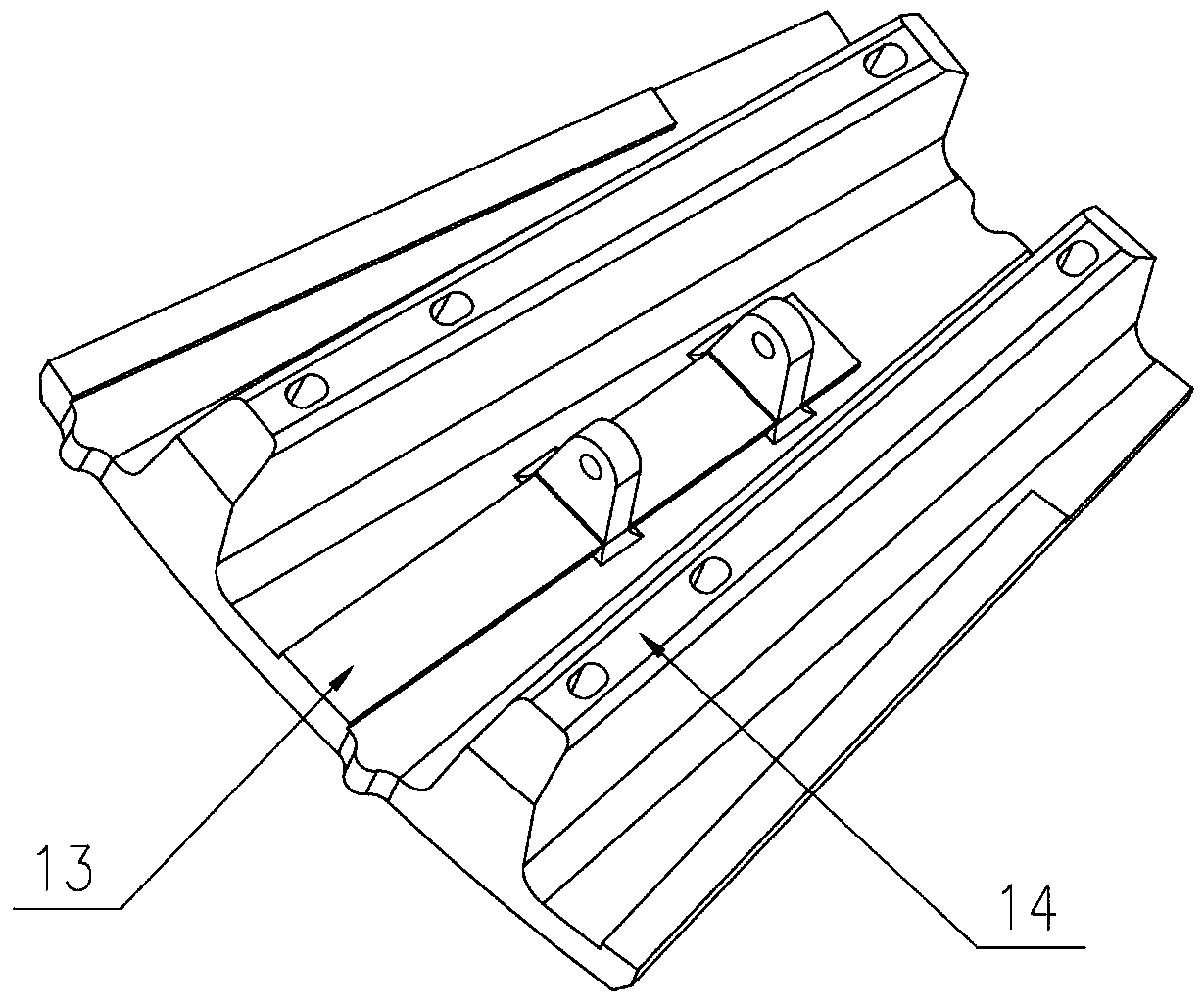

[0021] Such as Figure 1-8 As shown, the wear-resistant liner for the large autogenous mill / semi-autogenous mill includes a liner at the feed end, a liner at the cylinder body, a liner at the discharge end, and a liner for connecting the liner at the feed end and the liner at the cylinder body. plate and the filling ring 12 of the discharge end liner and cylinder liner, the feed end liner includes the feed end inner ring liner 1, the feed end middle ring liner 2 and the feed end outer ring liner connected in sequence Plate 3, cylinder liner includes feed end cylinder liner 4, intermediate section cylinder liner 5 and discharge end cylinder liner 6, discharge end liner includes outer ring pulp lifter 7, grating plate 8 , the inner ring slurry lifter 9, the discharge end cover plate 10, the discharger 11; The first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com