Overlapped turbine type bead separator of medium stirring mill

A turbine type, stirring mill technology, applied in grain processing and other directions, can solve the problems of heat-sensitive material grinding limitation, separation device failure, grinding efficiency reduction, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

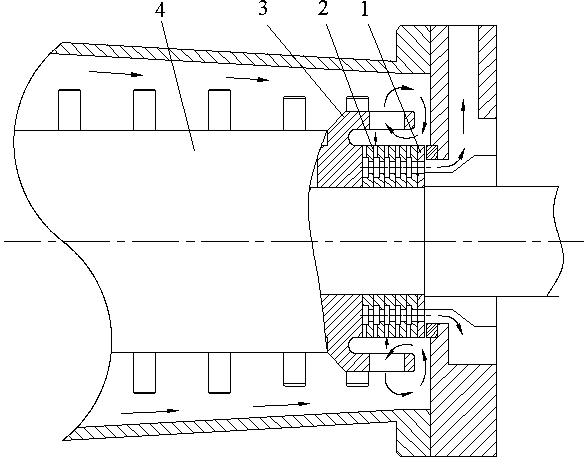

[0012] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, the stacked turbine type high-efficiency bead separator of the present invention includes: a static ring 1, a stacked turbine combination 2 and an outer turbine 3. The static ring 1 is mounted on the end plate of the grinding chamber, the outer turbine 3 and the stirring rotor are installed together, the left end of the stacked turbine group 2 is closely attached to the outer turbine 3, and the right end is placed on the shoulder of the shaft to keep an appropriate distance with the static ring 1. Discharge gap (adjustable). The size of the gap depends on the viscosity of the slurry to be ground, the diameter of the grinding beads and the output requirements.

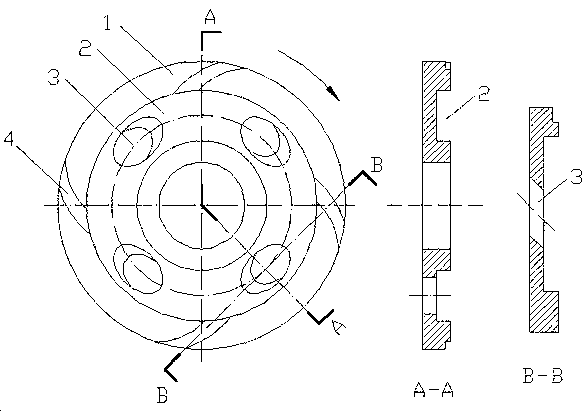

[0013] Such as figure 2 As shown, the turbine lamination set described in the present invention has the same size and structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com