Powder material discharging method and powder medium-sized bulk container

A technology for medium-sized bulk containers and powder materials, which is applied to large-scale containers, containers, packaging, etc., can solve the problems of difficult manufacturing, increased investment in costs, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

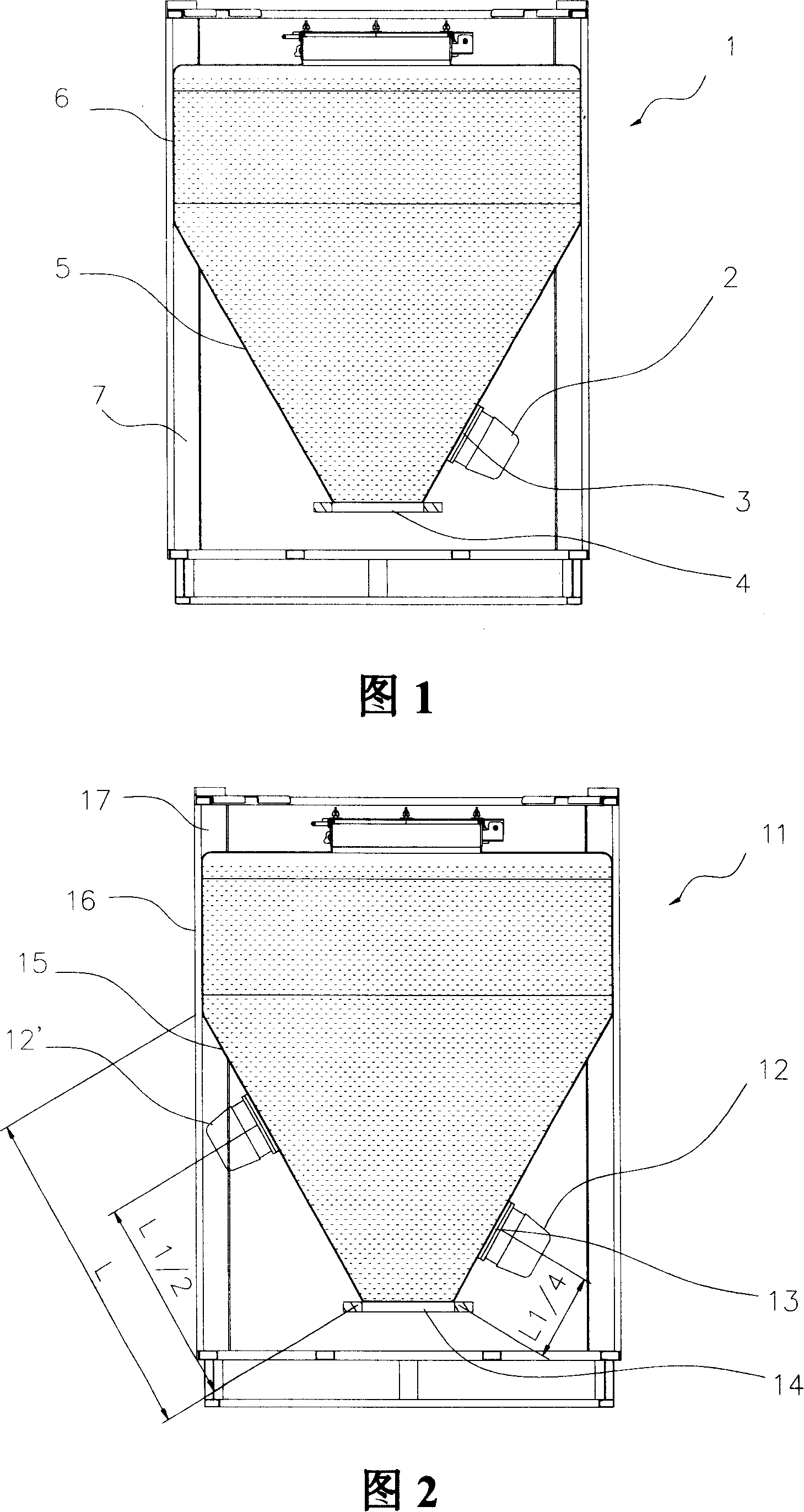

[0027] As shown in Figure 1, it is a preferred powder intermediate bulk container of the present invention, and this powder intermediate bulk container 1 includes a frame device 7 and a cylinder 6 fixed on the frame device 7, and the lower end of the cylinder 6 is connected with a The lower head 5 of the slope, the bottom of the lower head 5 is provided with a discharge port 4, the cylinder 6 and the lower head 5 define a storage space (not shown) for storing powder materials, and are all located in this Inside the frame unit 7. In particular, the powder intermediate bulk container 1 of the present invention also includes at least one vibration device 2, which can be rigidly connected and installed on the lower head 5 or / and the outer surface of the cylinder body 6 through a base 3, that is, on the lower head 5 or / and a base 3 is welded on the outer surface of the cylinder 6, and the vibrating device 2 is connected and fixed to the base 3 by bolts.

[0028] The following take...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com