Mobile mining equipment

A kind of mining equipment and mobile technology, applied in the field of mobile mining equipment, can solve the problems of coal crushing, easy blockage, coal discharge inconvenience, etc., achieve the effect of smooth discharge process and prevent blockage of discharge port

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

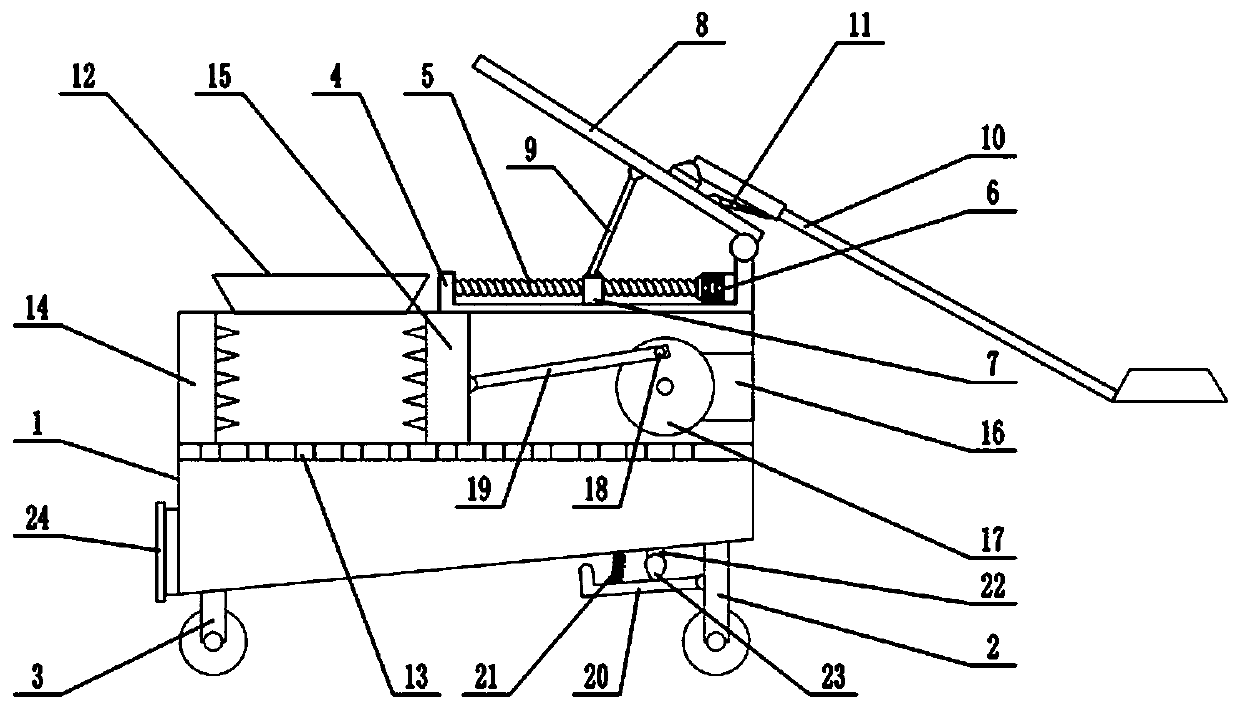

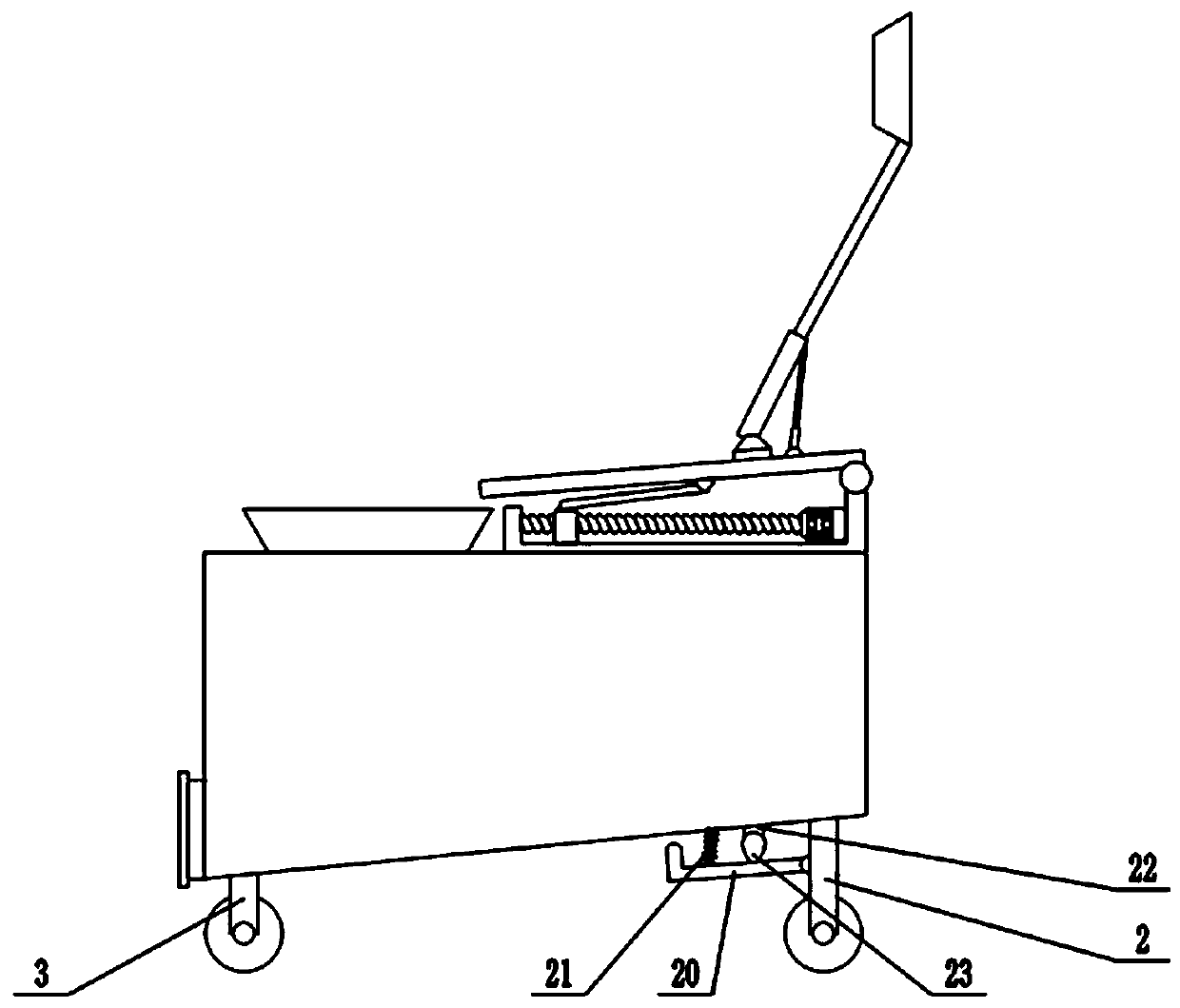

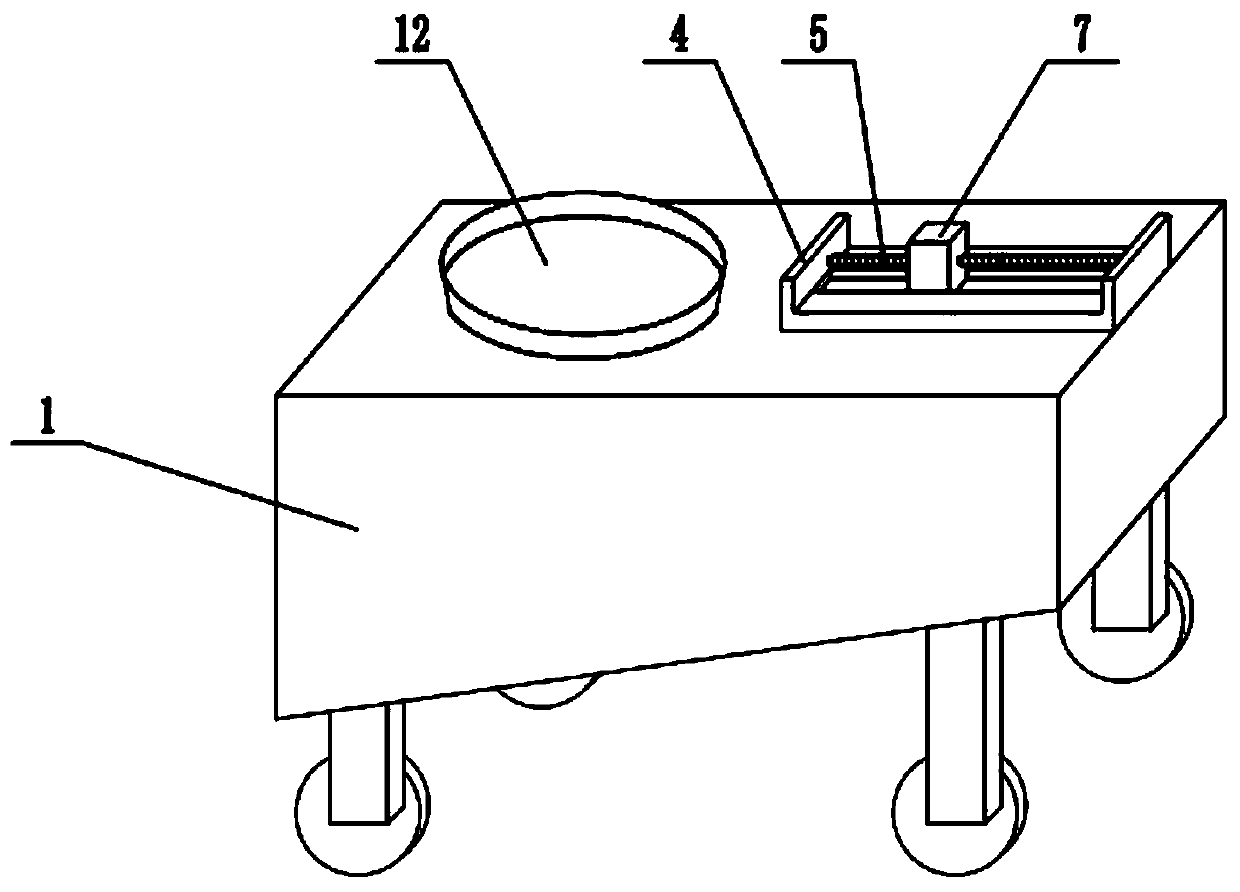

[0020] see Figure 1-3 , in the embodiment of the present invention, a kind of mobile mining equipment comprises housing 1, front wheel bracket 2, rear wheel bracket 3, movable plate 8 and bucket 10, and the bottom of housing 1 is installed with front wheel bracket 2, rear wheel bracket 3. The front wheel bracket 2 and the rear wheel bracket 3 are respectively equipped with rollers to facilitate the movement of the device. The upper surface of the housing 1 is fixedly connected with a fixed frame 4, and the inner wall of the fixed frame 4 is fixedly connected with a first motor 6. , the first motor 6 is a forward and reverse motor, the shaft extension end of the first motor 6 is equipped with a screw rod 5, the end of the screw rod 5 is rotatably connected with the side wall of the fixed frame 4, and a slider is set on the screw rod 5 7. The slider 7 is threadedly connected with the screw rod 5, and the lower surface of the slider 7 is slidably connected with the fixed frame 4...

Embodiment 2

[0022] On the basis of Embodiment 1, a percussion hammer 20 is provided below the housing 1, the end of the percussion hammer 20 is hinged with the front wheel bracket 2, and the middle part of the percussion hammer 20 is fixedly connected with an extension spring 21, and the end of the extension spring 21 The upper end is fixedly connected with the bottom of the casing 1, and under the action of the extension spring 21, the percussion hammer 20 can strike the bottom of the casing 1, and the lower surface of the casing 1 is fixedly connected with a third motor 22, and the shaft extension end of the third motor 22 A cam 23 is sleeved, and the cam 23 abuts against the middle part of the hammer 20, starts the third motor 22, drives the cam 23 to rotate, and when the protruding part of the cam 23 contacts with the hammer 20, drives the hammer 20 rotates downwards, and the cam 23 continues to rotate. Under the action of the tension spring 21, the hammer 20 is driven to rotate upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com