Crushing and dedusting equipment for mining stone

A technology for dust removal equipment and stone materials, which is applied to swirling devices, devices whose axial directions of swirling can be reversed, and grain processing, etc., can solve the problems of crushers without dust removal devices, easily causing pollution, and inconvenient for promotion and implementation, etc. To achieve the effect of easy promotion and implementation, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

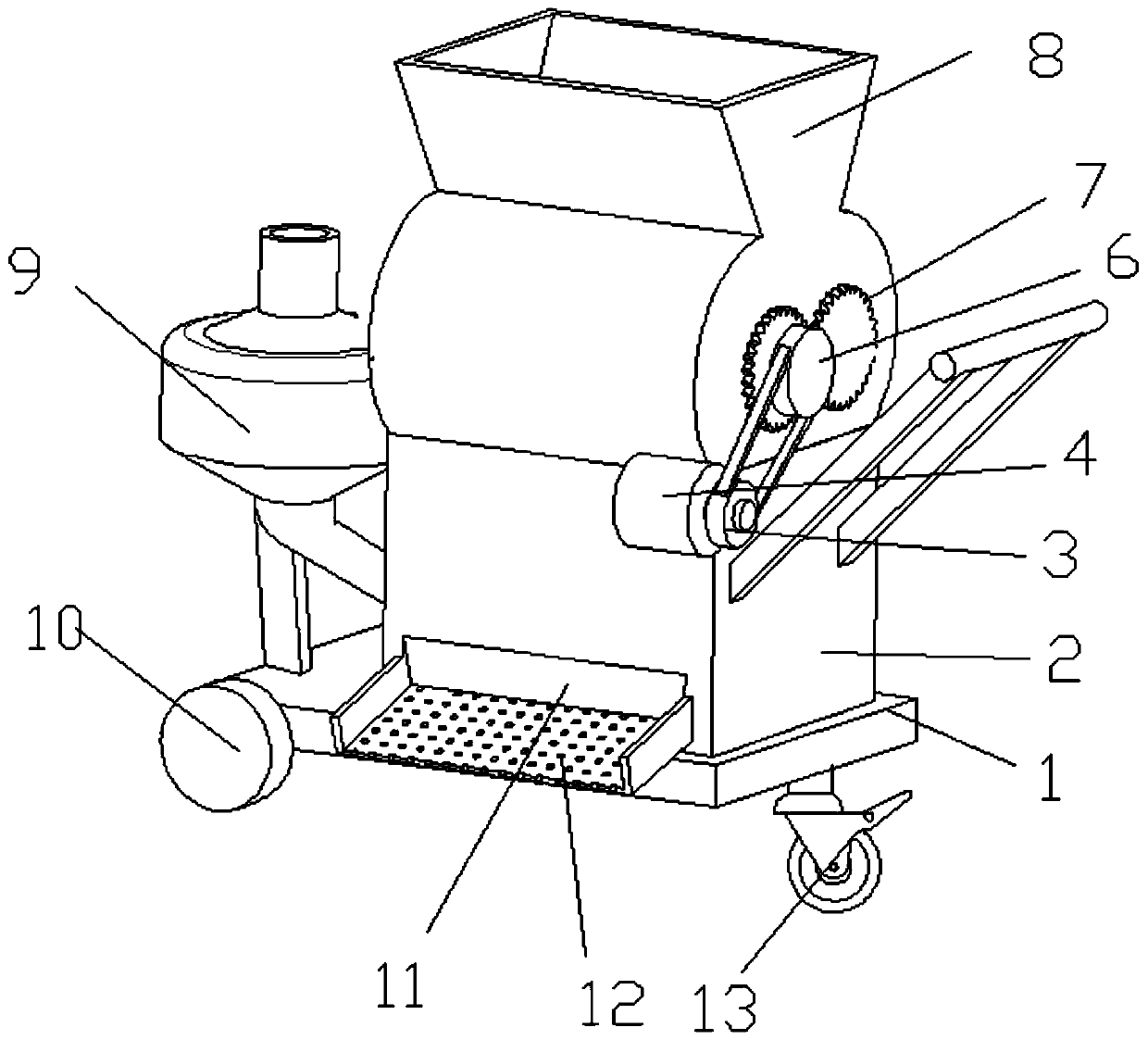

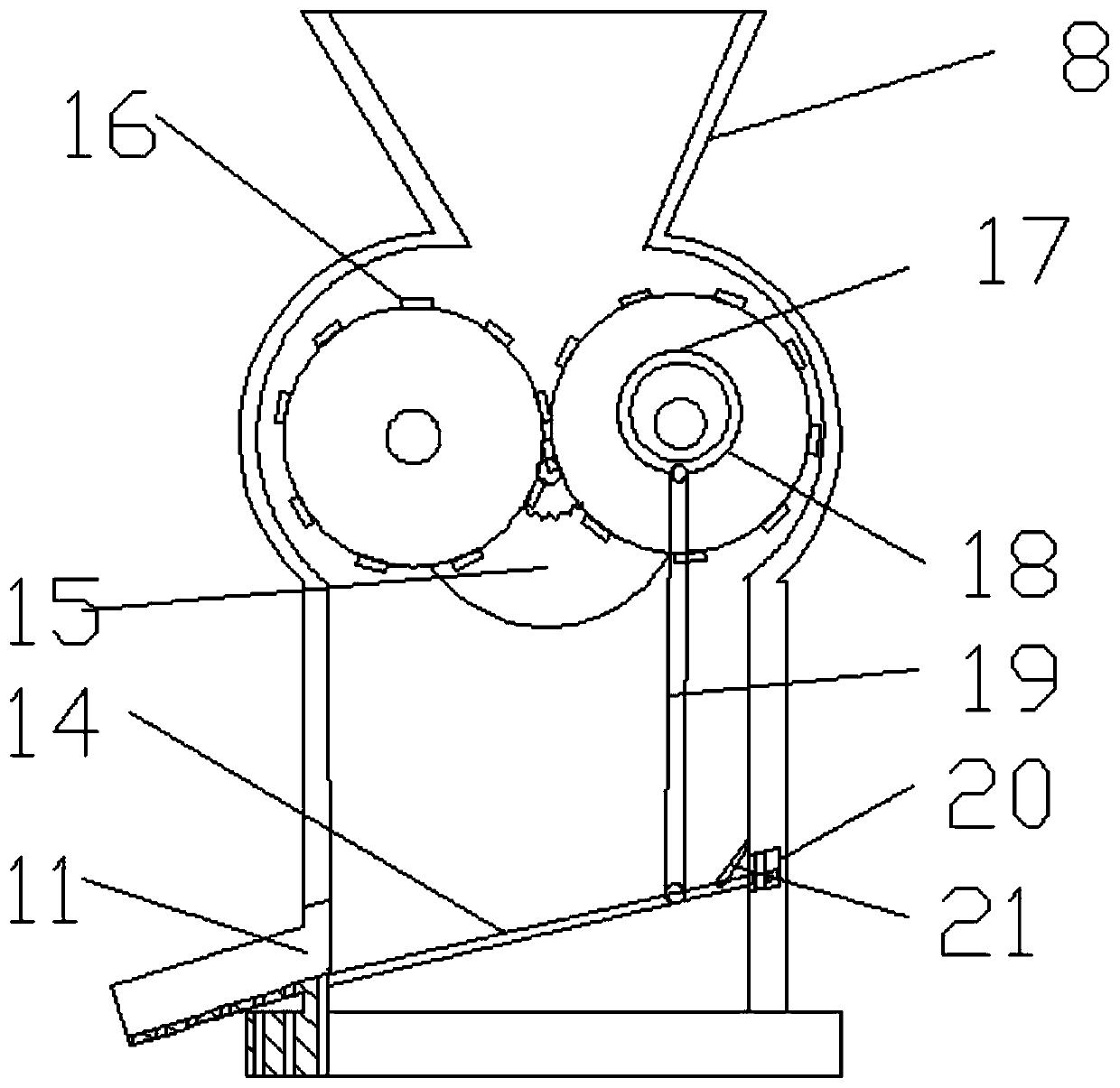

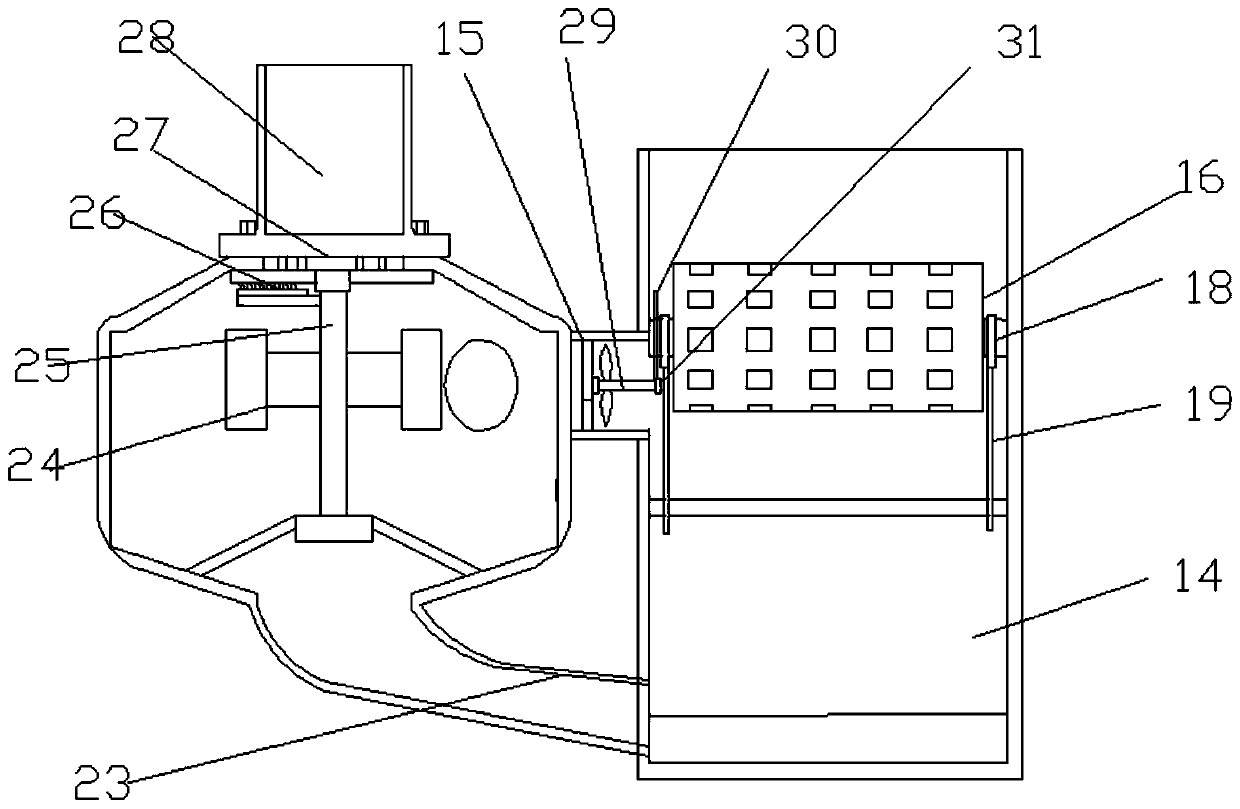

[0025] see Figure 1-3 , a kind of crushing and dedusting equipment for mine stone, comprising a base 1, a crushing shell 2 and a cyclone separator 9, the bottom of the base 1 is provided with a rotating wheel 10, the setting of the rotating wheel 10 is convenient for the movement of the base 1, and the bottom of the base 1 is provided with The universal wheel 13 is provided with a clamping plate, which has a braking effect on the universal wheel 13, and the universal wheel 13 and the rotating wheel 10 are arranged to facilitate the movement and fixing of the base 1. A crushing shell 2 and a cyclone separator 9 are fixedly installed on the base 1, and the top of the crushing shell 2 is communicated with a trough-shaped feed hopper 8, and the inside of the feed hopper 8 holds ores to be crushed. Below the feed hopper 8, there are two flat crushing rollers 16 rotating inside the crushing shell 2. One end of the crushing rollers 16 protrudes from the inside of the crushing shell ...

Embodiment 2

[0030] On the basis of Embodiment 1, an inclined sieve plate 12 is fixedly installed inside the crushing shell 2 on the outside of the discharge port 11. The setting of the sieve plate 12 is convenient for screening the crushed gravel, thereby facilitating the crushing. Stones are sieved for grading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com