Quantitative and continuous tailings discharging system and method of coarse slime sorting machine

A sorting machine and coarse coal slime technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of unsmooth discharge continuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given hereby, and the details are as follows:

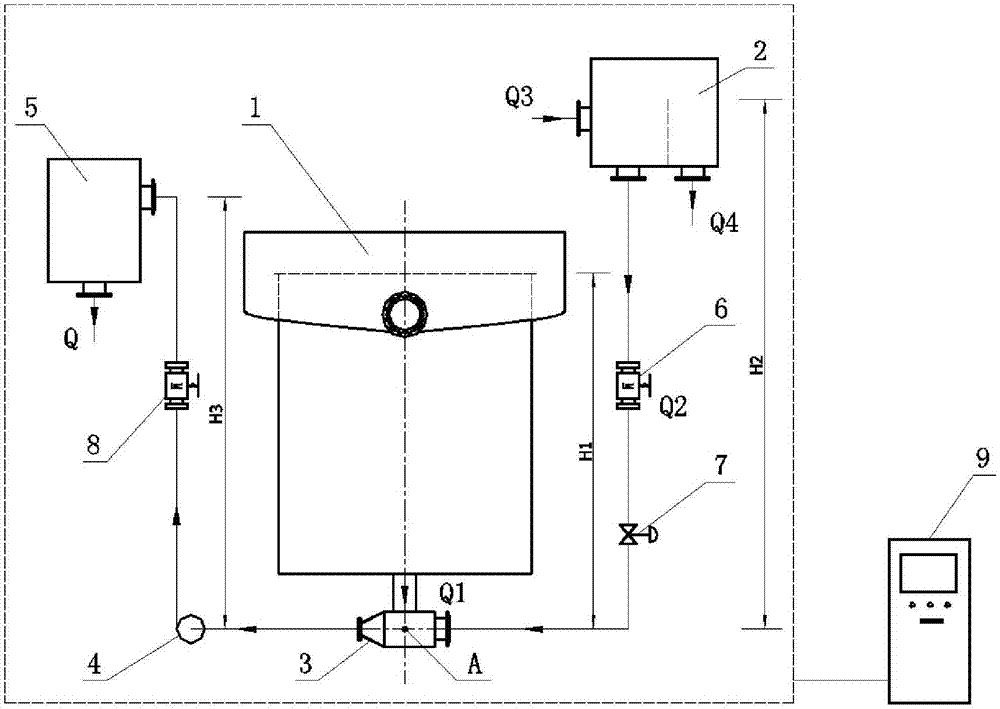

[0028] see Figure 1 to Figure 3 1. A system for quantitative and continuous discharge of tailings of a coarse coal slime separator, a coarse coal slime separator; the coarse coal slime separator includes a separator cylinder 1, and The upper end of 1 is provided with an overflow weir; the lower end of the sorting machine cylinder 1 is connected with the feeding pipe of the discharging pump through the first branch pipe and the discharging mixing box 3 in turn, and the feeding pipe of the discharging pump is located at On the horizontal plane; the geometrical height difference between the overflow weir and the feed pipe of the discharge pump is a constant H 1 , the top of the sorting machine cylinder 1 is provided with a water replenishment surge tank 2 and a discharge steady flow tank 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com