Lining bag for middle-sized bulk container

A medium-sized bulk container and liner bag technology, applied in the field of liner bags, can solve the problems of resource waste, difficult operation, time-consuming, etc., and achieve the effects of increasing utilization, saving costs, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0039] The liner bag of the present invention is generally used to contain liquid substances, especially viscous liquids such as grease, shower gel, hairspray, honey and the like. During transportation, liner bags are usually installed in IBCs.

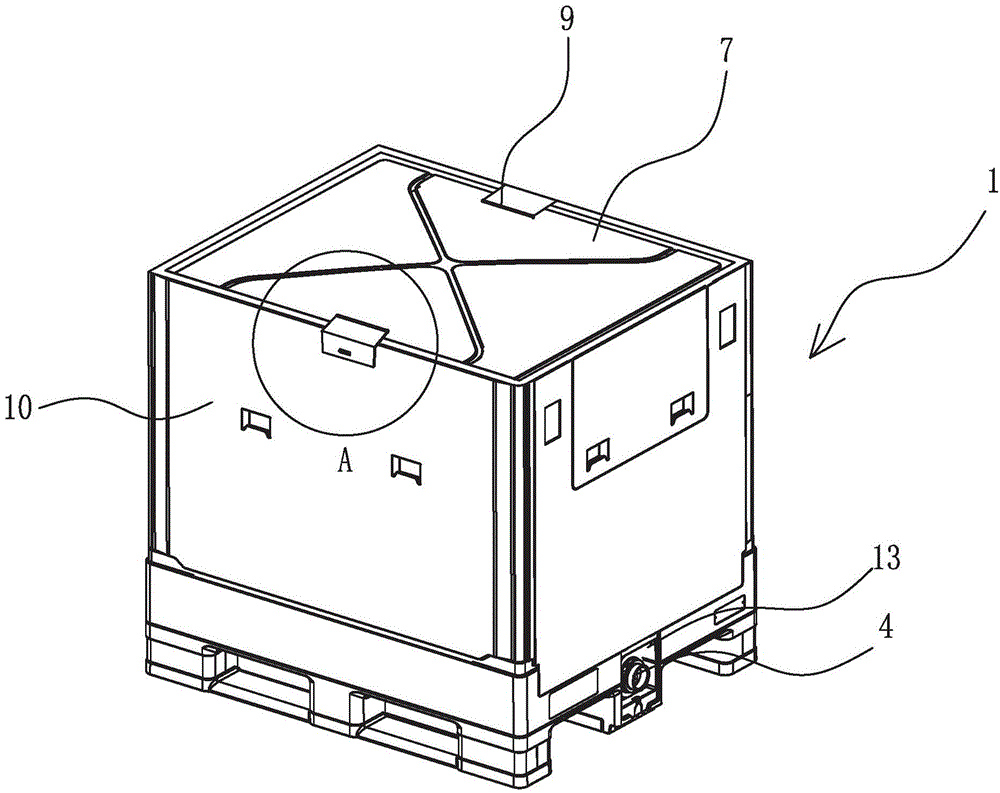

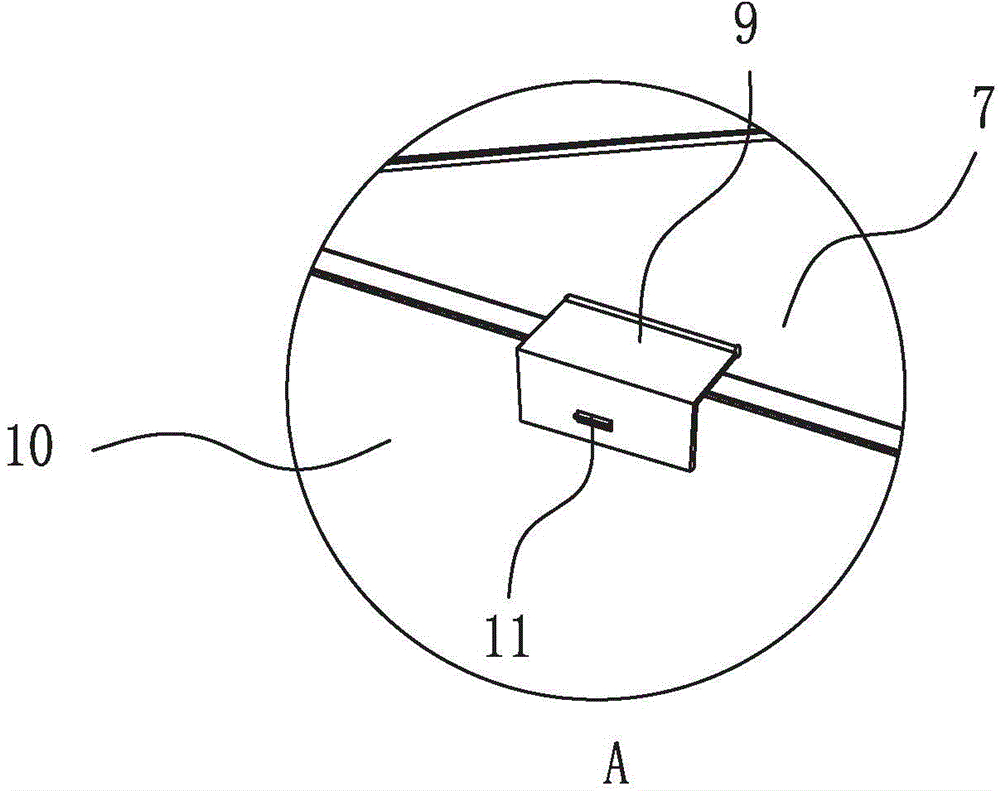

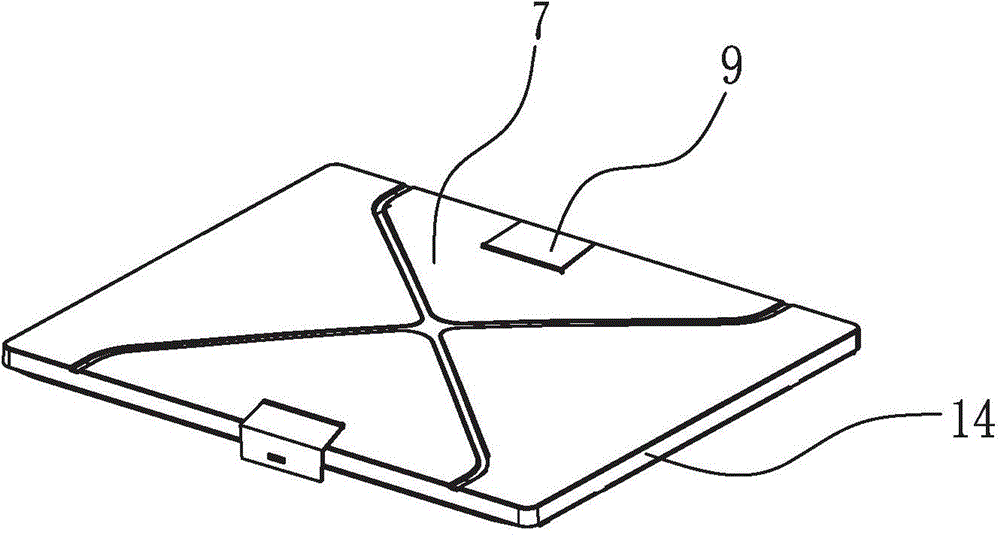

[0040] figure 1 It is a perspective view of an IBC 1 including a liner bag according to the first embodiment of the present invention. Figure 2a yes figure 1 Enlarged view of part a in middle; Figure 2b-2c yes figure 1 Schematic diagram of the structure of the removable cover of an IBC in . Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com