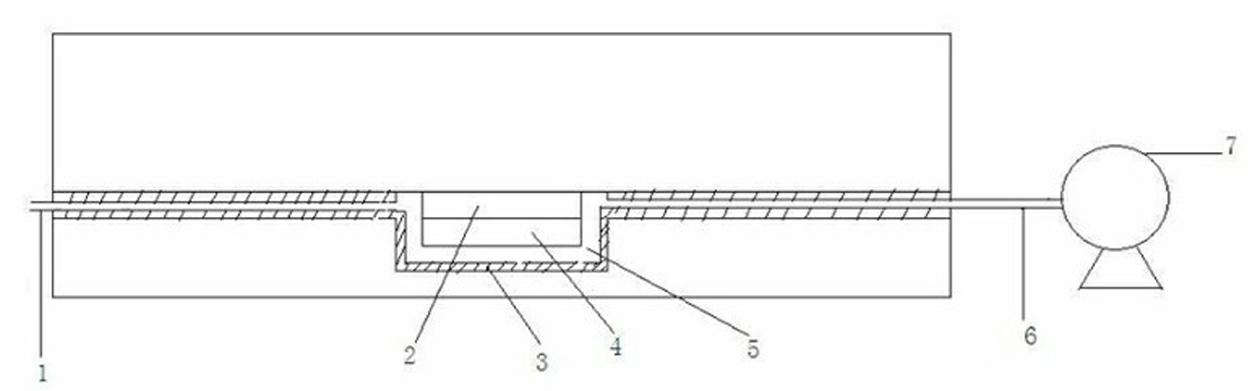

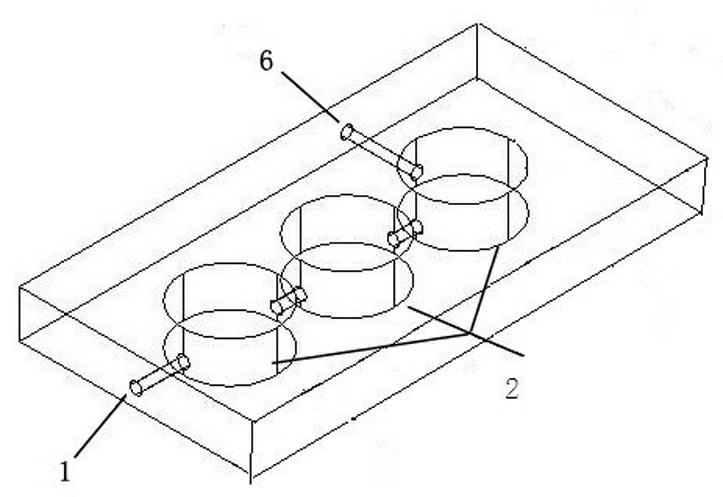

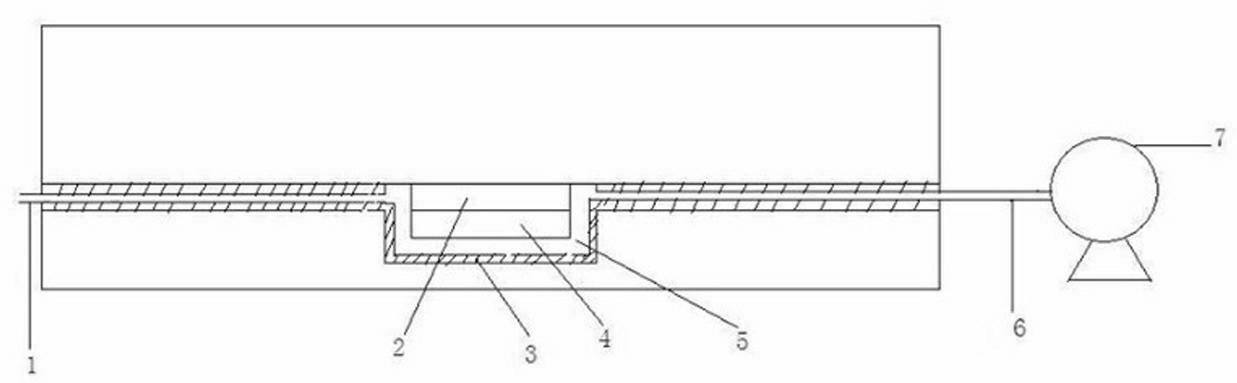

Structure of test cavity

A test chamber and transducer technology, applied in the field of test chamber structure, can solve the problems of high sensor detection limit value, large sensor detection error, and long sensor response time, so as to promote practicality and popularization, reduce detection error, and improve The effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] A test chamber structure, including an airflow inlet, a transducer, an inner wall medium layer, a sensitive film, a test chamber, an airflow outlet, and an air pump. The test chamber and the air pump are connected through capillary tubes to reduce the inflated volume inside the test chamber. The three-dimensional At least one dimension is on the order of microns, and the cross-sectional size of the gas path connecting the outside world and the test chamber is on the order of microns to millimeters. The transducer is a part of the inner wall of the test cavity or is arranged in the test cavity. The material of the capillary is one of semiconductor materials such as silicon, silicon dioxide, gallium arsenide, and silicon nitride. The inner wall medium layer of the test chamber is made of low surface tension and chemically inert material o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com