Method for extracting limonene from rosin

A technology of limonene and turpentine, applied in chemical instruments and methods, purification/separation of hydrocarbons, organic chemistry, etc., to achieve the effect of facilitating filtration, high purity and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

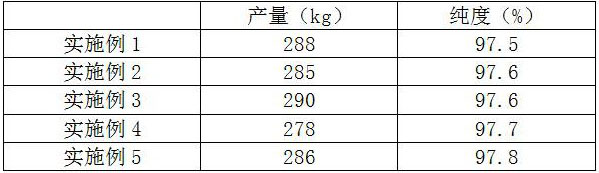

Examples

Embodiment 1

[0025] A method for extracting limonene from pine resin, comprising the following steps:

[0026] (1) Pass the turpentine through the sieve plate after being crushed. The sieve hole specification of the sieve plate is 10mm in length and 0.1mm in width. Then, turpentine with 15% turpentine quality and 8% turpentine with turpentine quality are successively added to the crushed turpentine. Clear water, then add pure phosphoric acid with 0.05% turpentine quality and mix, then directly pass into steam and heat to 90°C and keep the temperature until the rosin is completely melted to obtain turpentine liquid; the rosin can be selected from Guangxi Gaozhi Songyouzhu. The main components of purified turpentine are ①α-pinene 54.5-69.07%; ②β-pinene 4.25-7.7%; ③camphene 1.24-1.49%; ④limonene 21.53-35.6%;

[0027] (2) Filter the turpentine resin liquid obtained in step (1), then send it to a water washer for washing treatment, and then let it stand for clarification for 15 hours to obtain ...

Embodiment 2

[0032] A method for extracting limonene from pine resin, comprising the following steps:

[0033] (1) Pass the turpentine through the sieve plate after being crushed. The sieve hole specification of the sieve plate is 12mm long and 0.3mm wide, and then add turpentine with 25% turpentine mass and 9% clear water with turpentine mass to the crushed turpentine , then add pure phosphoric acid with 0.07% turpentine quality and mix, then directly pass into steam and heat to 93°C and keep the temperature until the rosin is completely melted to obtain turpentine liquid; the rosin can be selected from Guangxi Gaozhi Songyouzhu. The main components of the processed turpentine are ① α-pinene 54.5-69.07%; ② β-pinene 4.25-7.7%; ③ camphene 1.24-1.49%; ④ limonene 21.53-35.6%;

[0034] (2) Filter the turpentine resin liquid obtained in step (1), then send it to a water washer for washing treatment, and then let it stand for clarification for 10 hours to obtain a clarified resin liquid; 15%, t...

Embodiment 3

[0039] A method for extracting limonene from pine resin, comprising the following steps:

[0040] (1) Pass the turpentine through the sieve plate after being crushed. The sieve hole specification of the sieve plate is 15mm long and 0.2mm wide, and then add turpentine with 20% turpentine mass and clear water with 10% turpentine mass to the crushed turpentine , then add pure phosphoric acid with 0.1% turpentine quality and mix, then directly pass into steam and heat to 95°C and keep the temperature until the rosin completely melts to obtain turpentine resin liquid; the rosin can be selected from Guangxi Gaozhi Songyouzhu. The main components of the processed turpentine are ① α-pinene 54.5-69.07%; ② β-pinene 4.25-7.7%; ③ camphene 1.24-1.49%; ④ limonene 21.53-35.6%;

[0041] (2) Filter the turpentine resin liquid obtained in step (1), then send it to a water washer for washing treatment, and then let it stand for clarification for 20 hours to obtain a clarified resin liquid; 15%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com