Method and device for detaching a component which is attached to a flexible film

A film and component technology, which is applied in the field of separating and device parts for bonding on a flexible film, can solve problems such as the position problem of the edge area of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

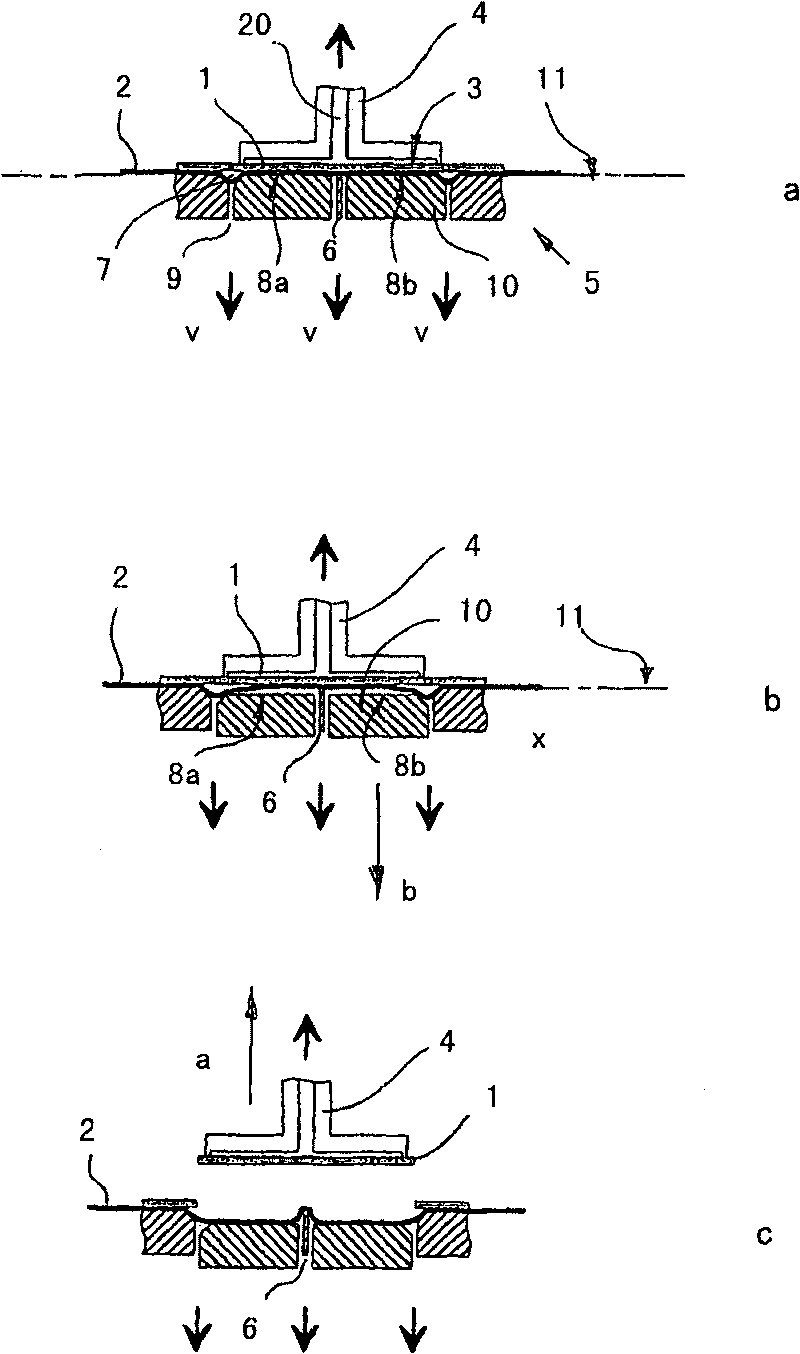

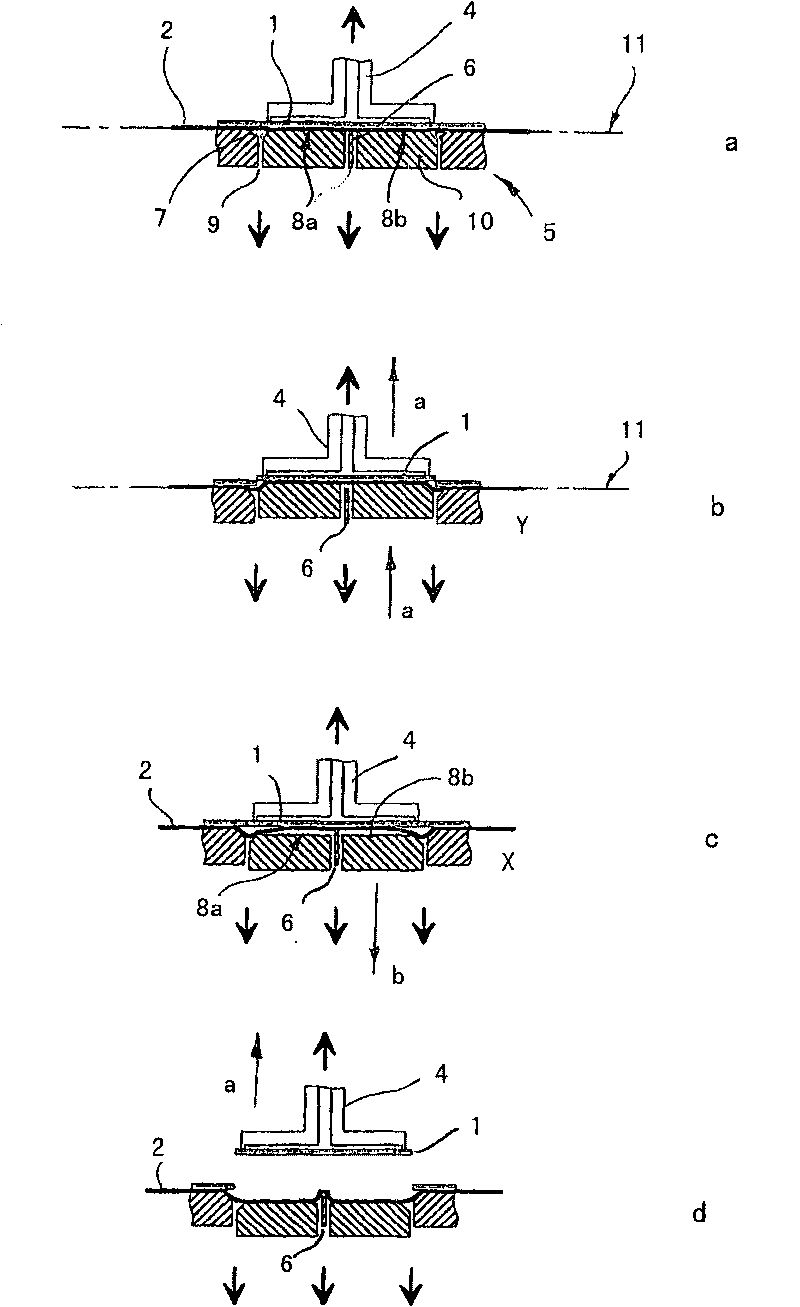

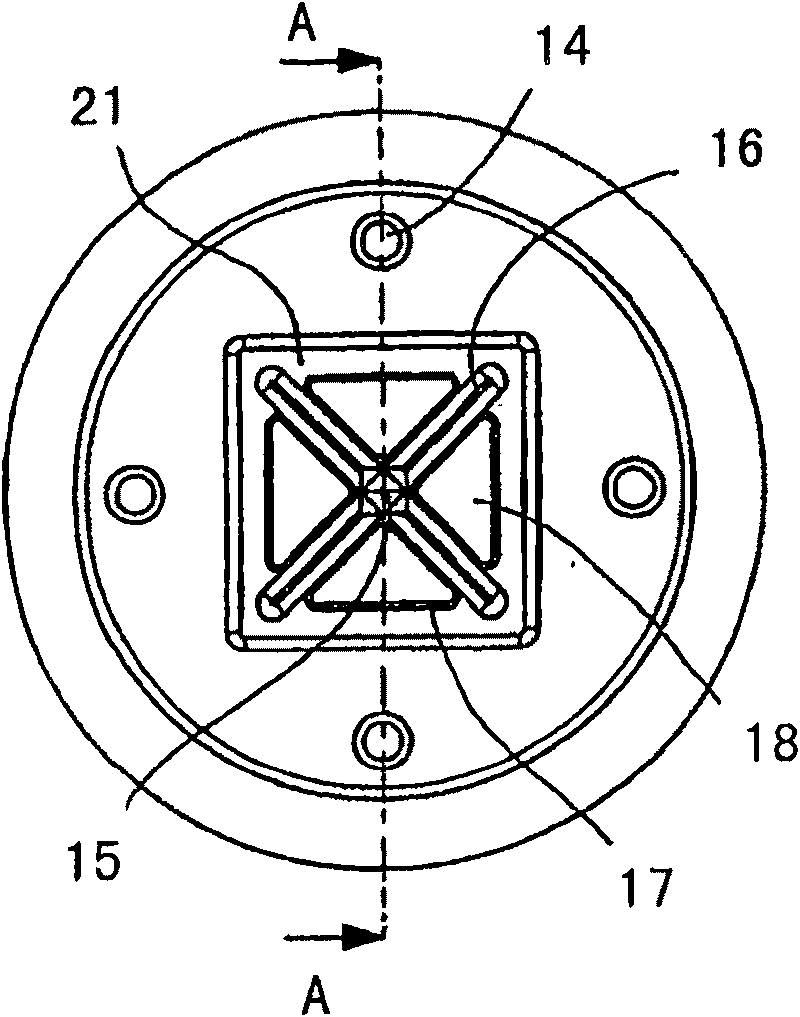

[0038] exist figure 1 A first embodiment of the split process with three steps is shown in a to 1c. Here, a plurality of chips 1 are glued onto a stretched wafer film 2, or the wafer that was bonded together is divided into individual chips by sawing. After sawing, the film is further tensioned in a known manner in order to facilitate the separation of the chips. The separate tool, indicated as a whole by 5, is only shown schematically here. It is arranged stationary in the working machine relative to the wafer film 2 . The placement of the chips 1 on the parting tool 5 takes place by means of an X-Y coordinate drive.

[0039] A holding tool 4 with a flat, suction-action holding surface can rest against the surface 3 of the chip facing away from the film. A negative pressure is applied to this surface via the negative pressure channel 20 , so that the chip adheres to the holding tool 4 . Holding tool 4 can be raised along arrow direction a under the situation of maintaini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com