Full-automatic filling system for multi-variety material buckets and filling method of system

A filling system and material barrel technology, which is applied in the field of automatic filling system for various material barrels, can solve the problems of high production cost, low production efficiency, single automatic filling function, etc., and achieve low production cost, high efficiency, The effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

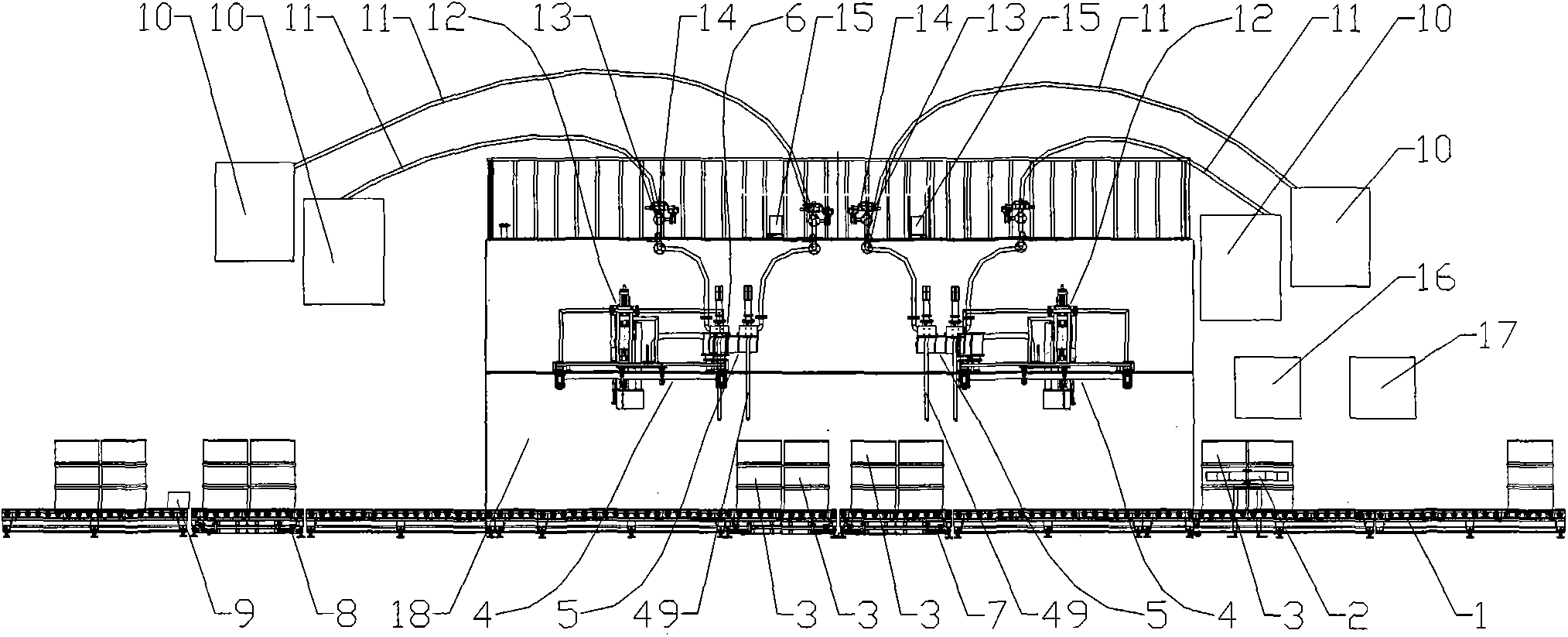

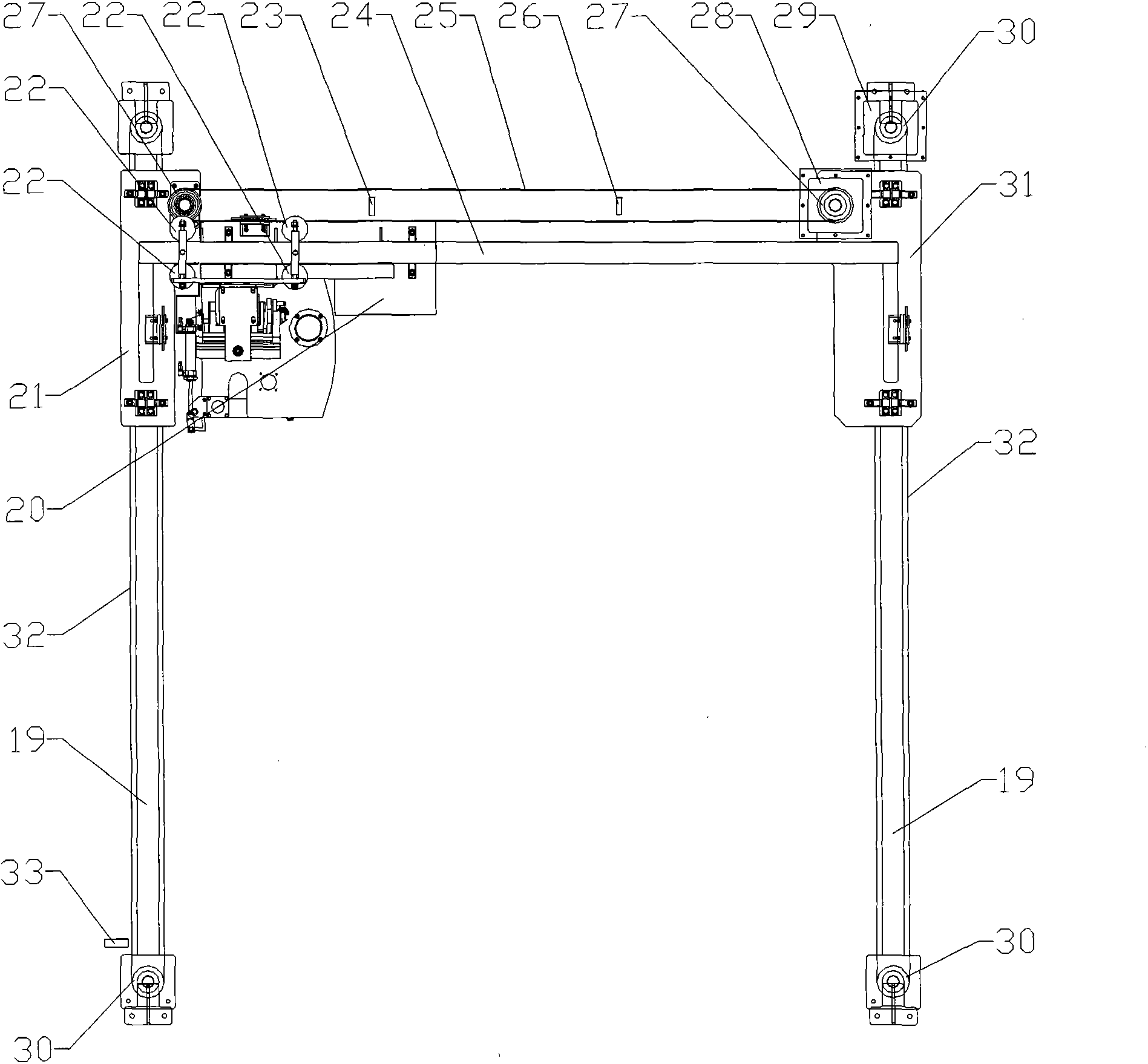

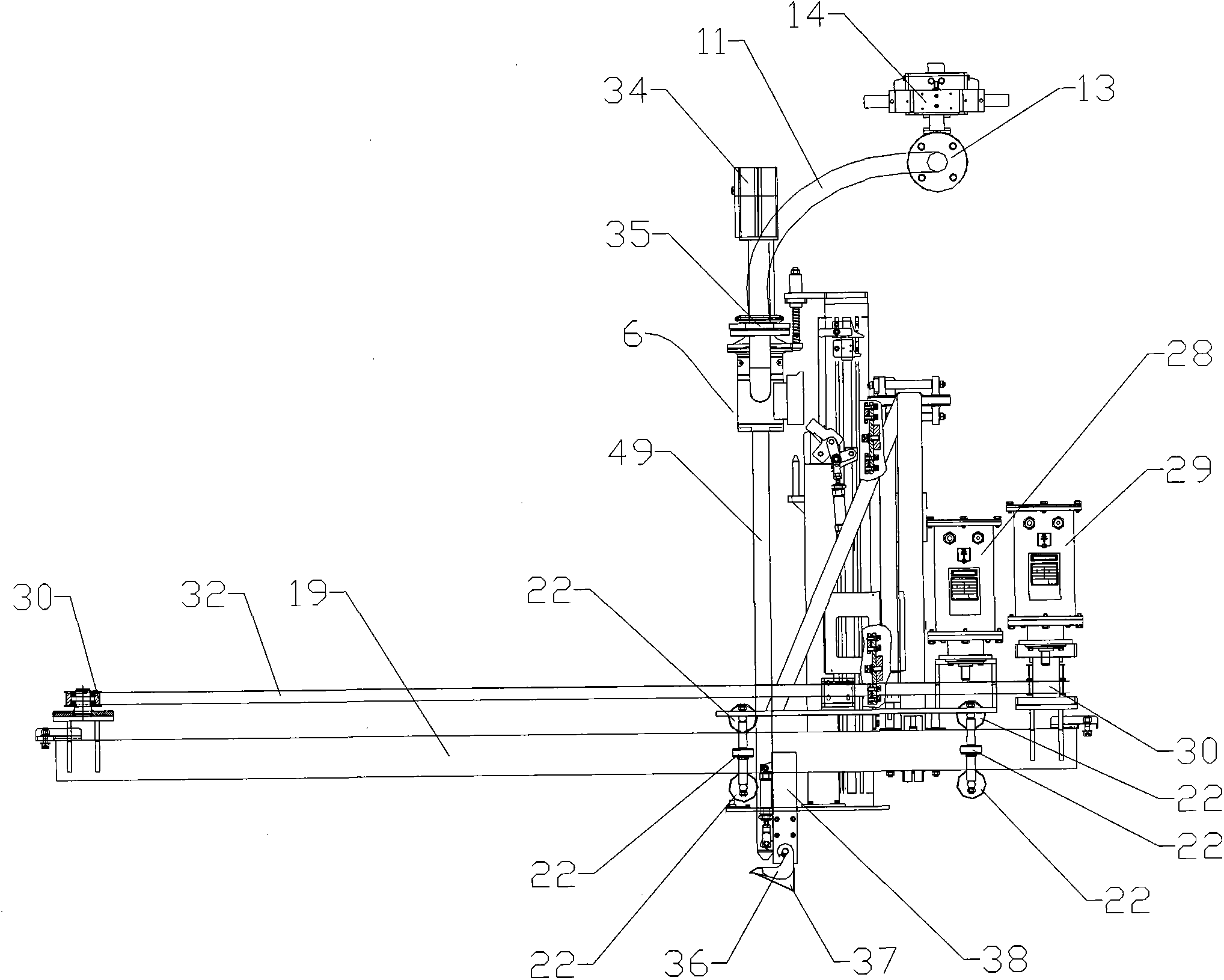

[0034] Embodiment 1: as attached figure 1 As shown, the automatic filling system for various material barrels includes a body 18, a controller 16 and a processor 17. Two groups of sliding mechanisms 4 are arranged on the body 18, and a filling mechanism 12 is arranged on the sliding mechanism 4. Through the sliding mechanism Move the filling mechanism 12 to the top of the material barrel 3, the filling mechanism 12 is provided with an automatic replacement mechanism, and the body 18 between the two sets of sliding mechanisms 4 is provided with two visual sensors 15, and the visual sensors 15 are located at the bottom of the body 18 On the upper end, the position and quantity of the barrel mouth of the material barrel 3 are recognized by the visual sensor 15 , and the visual sensor 15 is connected with the controller 16 and the processor 17 .

[0035] The lower part of the body 18 is provided with a conveying mechanism 1, and the conveying mechanism 1 is provided with a weighin...

Embodiment 2

[0057] Embodiment 2: a filling method of a multi-type material barrel automatic filling system, the filling method comprises the following steps:

[0058] According to the information of the filled material, the sliding mechanism 4 moves the automatic replacement mechanism to the predetermined position of the storage mechanism 5, and automatically picks up or replaces the filling system 6;

[0059] Slide mechanism 4 returns to predetermined initial position;

[0060] Put the empty barrel of material on the conveying mechanism 1, and the conveying mechanism 1 moves the empty barrel to the bottom of the visual sensor 15;

[0061] The visual sensor 15 recognizes the position and quantity of the mouth of the barrel, and the processor 17 sets the weight value of the filling material according to the result recognized by the visual sensor 15;

[0062] The sliding mechanism 4 moves the filling mechanism 12 above the mouth of the barrel to fill the material, and the weighing and meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com