Quickly detached and installed intermediate bulk container framework

A medium-sized bulk container and frame technology, applied in the field of packaging containers, can solve the problems of large occupation, waste of logistics capacity, increase of maintenance costs, etc., and achieve the effect of convenient stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

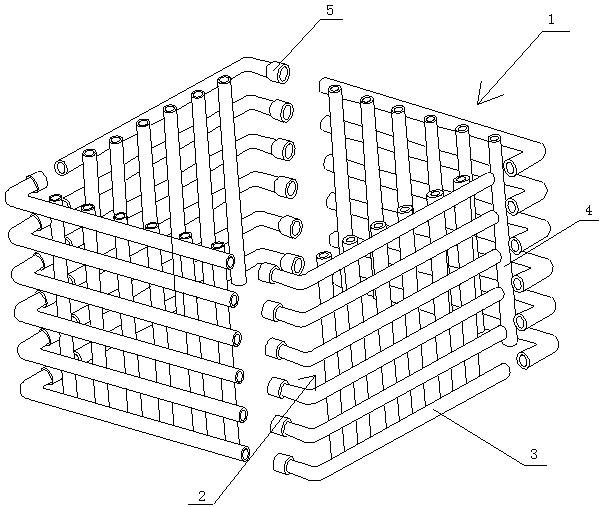

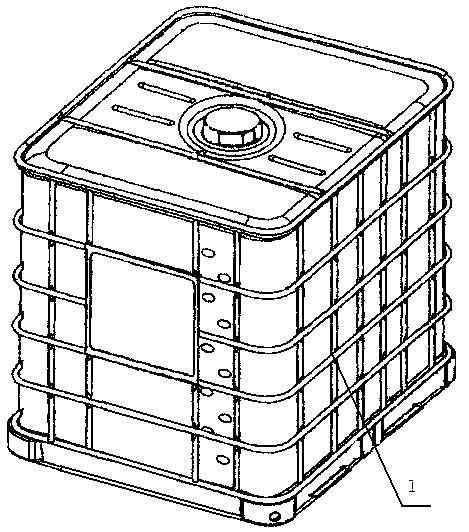

[0014] see Figure 1 to Figure 3 , the present invention relates to a quick disassembly and assembly medium-sized bulk container frame, comprising an outer frame 1, the outer frame 1 is composed of four frame components 2, and the frame component 2 is composed of a plurality of horizontal tubes 3 arranged in parallel up and down and a plurality of left and right The vertical tubes 4 arranged in parallel are welded together, wherein the horizontal tube 3 is in the shape of an "L", and the end of the short straight section of the horizontal tube 3 is provided with a sleeve 5, and the sleeve 5 is connected to an adjacent horizontal tube. The ends of the long straight sections of 3 are connected and fixed with bolts, so that the four frame components 2 can be easily installed and fixed to form the outer frame 1.

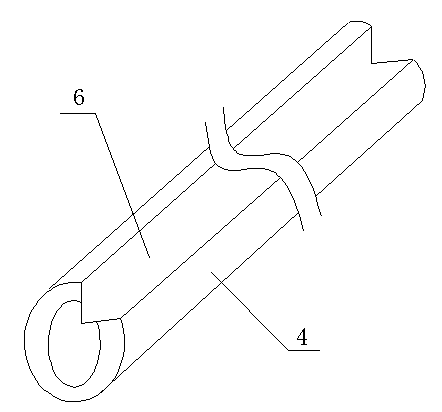

[0015] Both the horizontal tube 3 and the vertical tube 4 have grooves 6 on their surfaces, and the grooves 6 are in the shape of a "V".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com