Net-based baffles for flexible intermediate bulk containers

a technology of intermediate bulk containers and net-based baffles, which is applied in the direction of containers, bags, sacks, etc., can solve the problems of occupying considerable volume of idle spaces, affecting the sizing of present baffles, and unable to sew through the edges of present baffles, etc., to achieve the effect of volum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

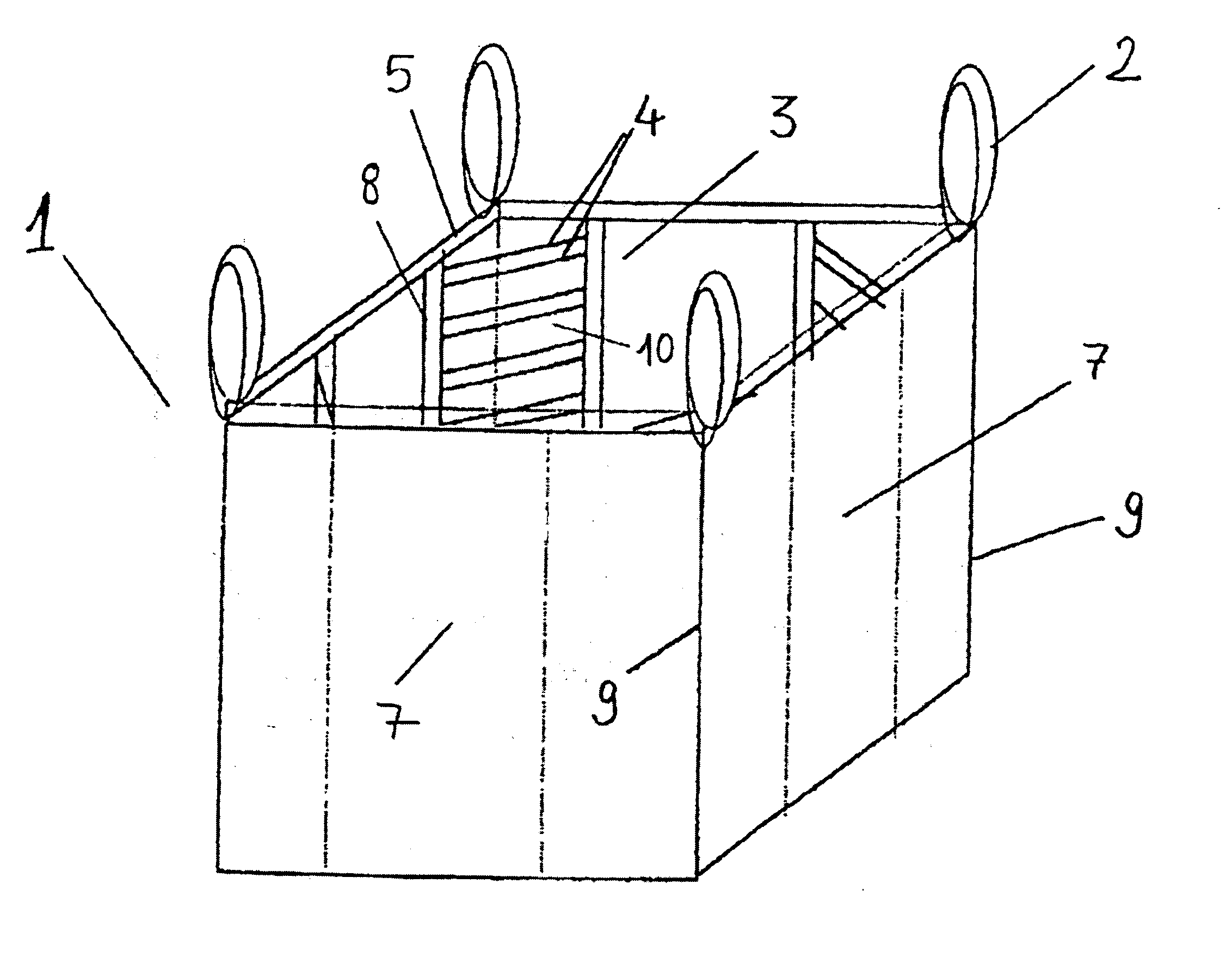

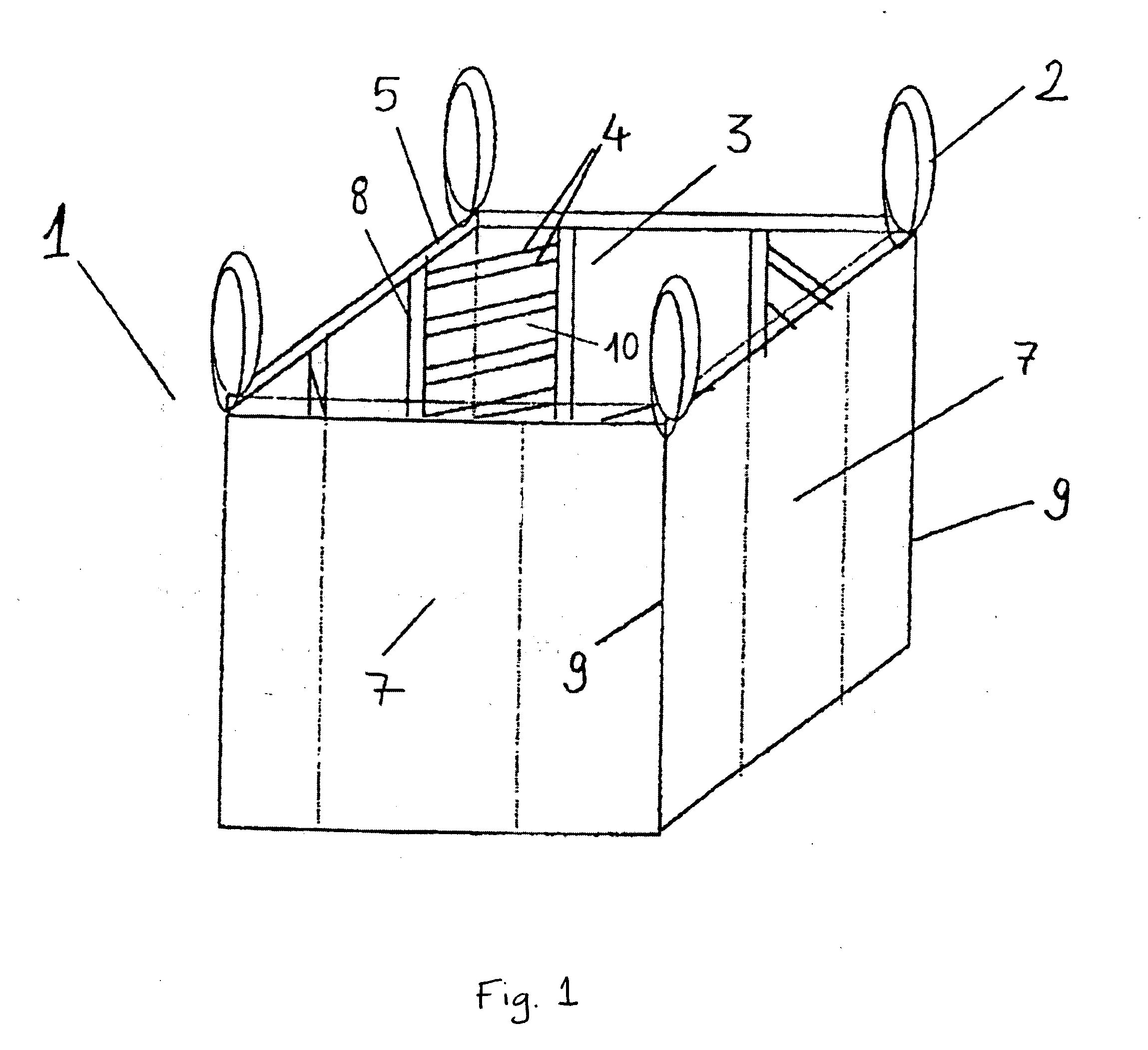

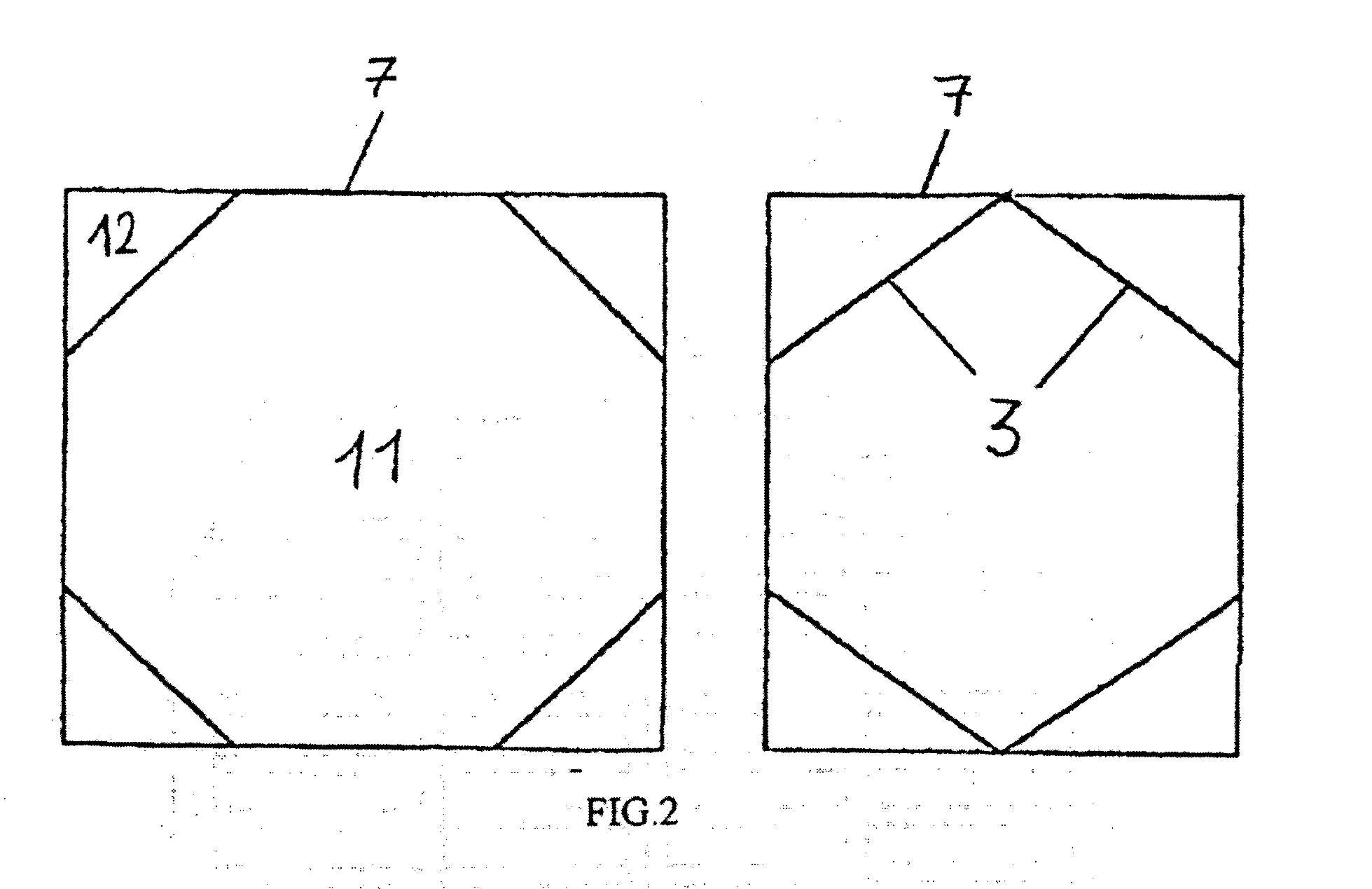

[0032] In FIG. 1, net-based baffles and the location thereof in the FIBC are illustrated. Conventionally, a FIBC, flexible intermediate bulk container (1) is a means for transferring materials and having a rectangular prism geometry carried by holders (2). The baffles (3) are sewed to the connection edges (9) of the FIBC (1) diagonally so as to obtain a relatively rounded geometry in the essential volume (11) of the FIBC, i.e. independent of sharp geometry due to edges. The lateral surfaces (7) are attached to each other by connection edges (9) so that the FIBC (1) is formed.

[0033] Net-based baffles (3) comprise preferably two vertically extending strips (8) and horizontally extending elements provided between the vertically extending strips, and net filaments (4). One of the vertically extending strips (8) is sewed to the lateral surface (7) and the inner one is embodied for connecting the net filaments (4) thereto. As an alternative structure, the vertically extending strips (8) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com