High temperature resistant environment-protective polychloroethylene material for electric wire and cable

A wire and cable, polyvinyl chloride technology, applied in the direction of insulated cables, cables, circuits, etc., to achieve the effects of good hand feeling, good compression and impact resilience, good mechanical and physical properties and insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1. High temperature resistant and environmentally friendly polyvinyl chloride material for wire and cable

[0058] Material formula:

[0059] components parts by weight Loose polyvinyl chloride resin - high degree of polymerization polyvinyl chloride resin, polyvinyl chloride resin

Alignment 2000~3000 100 TOPM plasticizer, flash point ≥ 260°C 35 Poly(1,2-trimethylene adipate), molecular weight 3000~4000 25 Calcium Zinc Stabilizer—High Temperature Calcium Zinc Stabilizer Grade 5℃~125℃ 13 Antioxidant 1010 1 Flame retardant - antimony trioxide 4 Filler - Calcium Carbonate 20 Filler - calcined kaolin 5 Lubricant—PE wax 0.7 Processing Modifier—ACR401 1

[0060] 2. Preparation process

[0061] Step 1: Weigh all the raw and auxiliary materials according to the formula, preheat the polyester plasticizer to 80°C, and then add polyvinyl chloride resin and calcium zinc stabilizer to knead at a...

Embodiment 2

[0065] Embodiment 2. High-temperature resistant and environmentally friendly polyvinyl chloride material for wire and cable

[0066] 1. Material formula

[0067] components parts by weight Loose polyvinyl chloride resin - high degree of polymerization polyvinyl chloride resin, polymerized

Degree 2000~3000 90 Plasticizer—TOPM plasticizer, flash point ≥ 260°C 38

[0068] Plasticizer—poly-1,3-butylene adipate, molecular weight 3000-4000 20 Calcium zinc stabilizer - 105 ℃ ~ 125 ℃ grade high temperature calcium zinc stabilizer 14 Antioxidant—1010 0.5 Antioxidant—168 0.5 Flame retardant - antimony trioxide 3 Flame Retardant—Zinc Borate 3 Filler - Calcium Carbonate 15 Filler - calcined kaolin 8 Lubricant - stearic acid 0.8 Processing aid—ACR401 1.1

[0069] 2. Preparation process

[0070] Same as embodiment one.

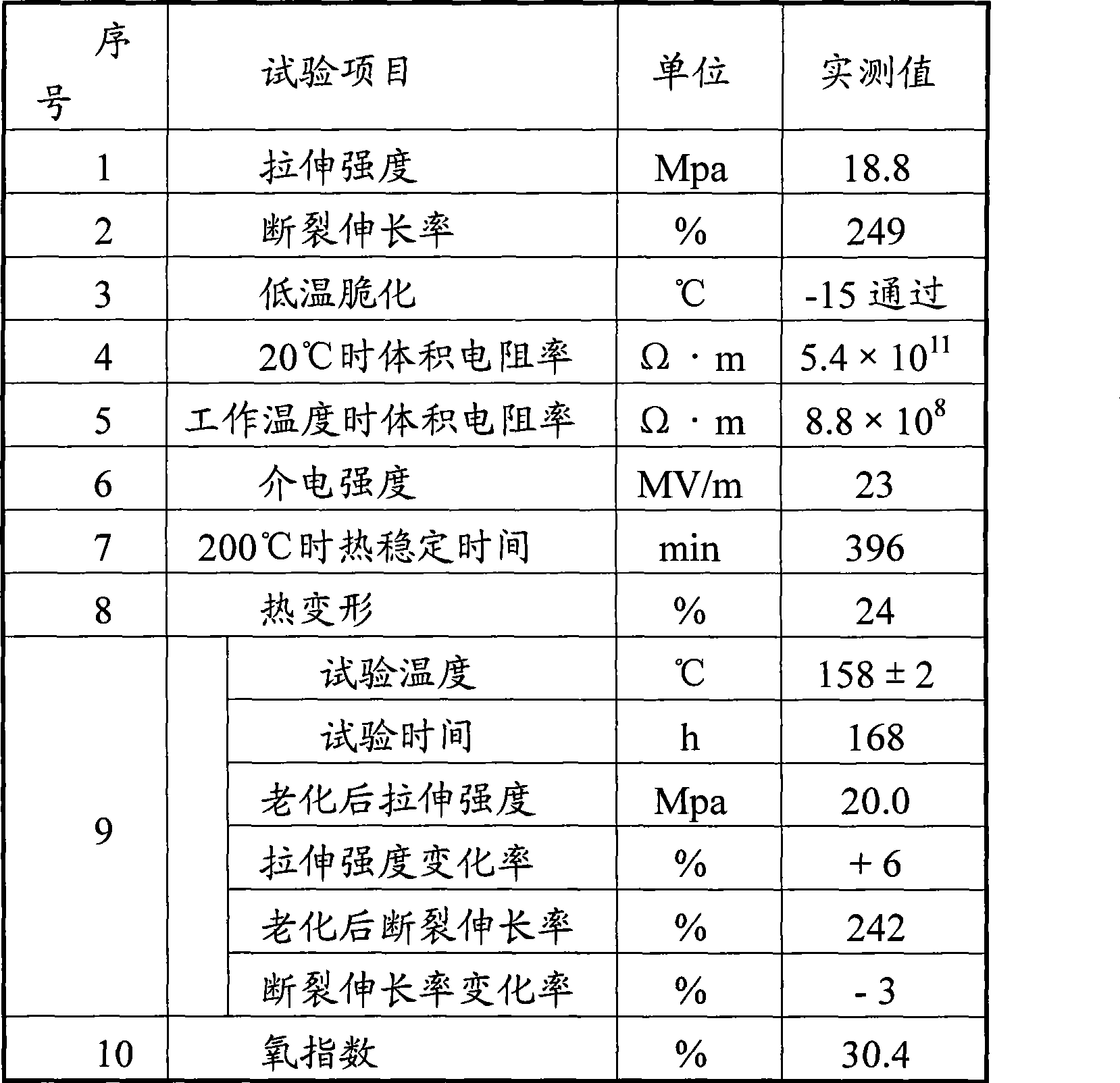

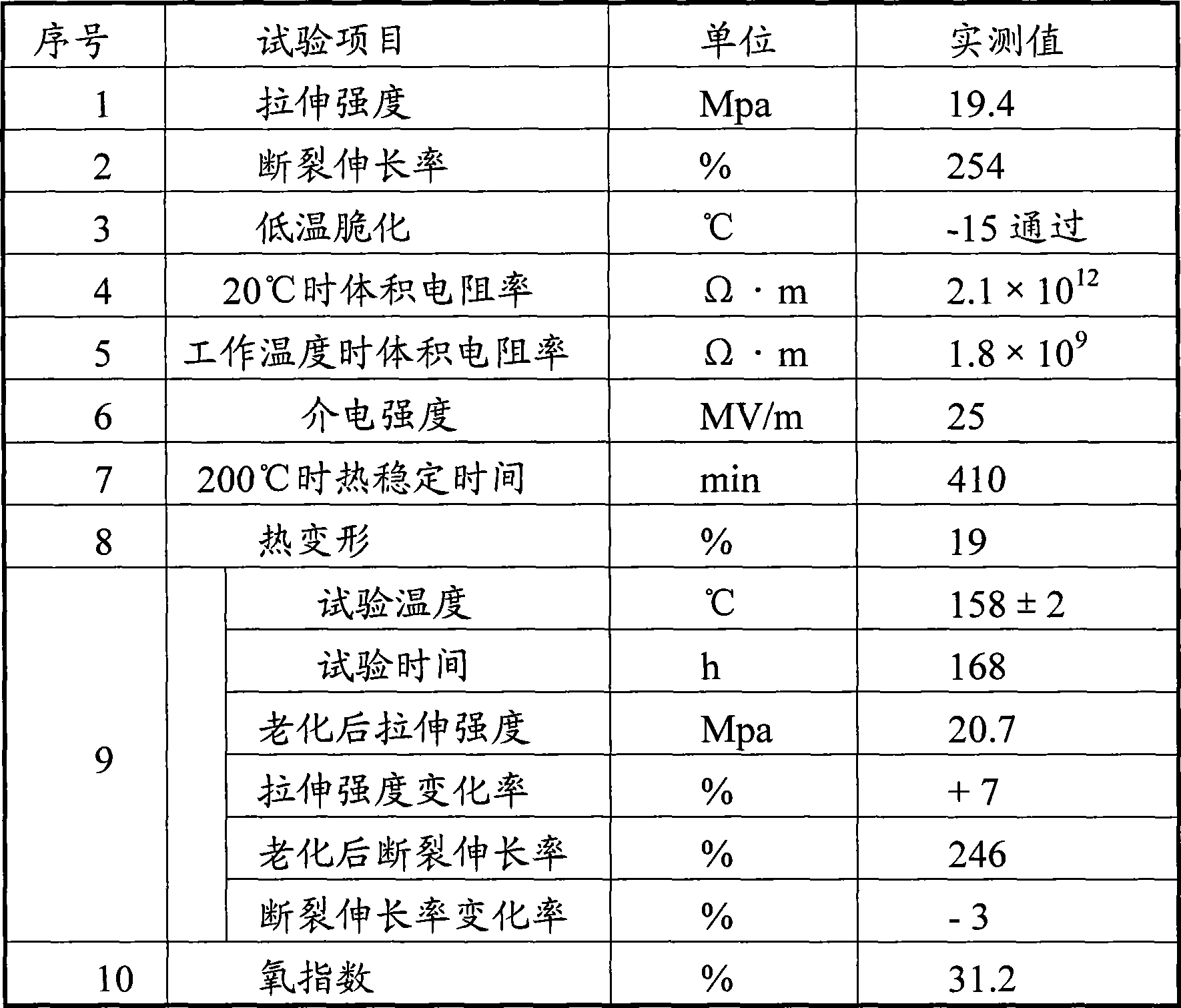

[0071] 3. Technical indicators

[0072]

Embodiment 3

[0073] Embodiment 3. High temperature resistant and environment-friendly polyvinyl chloride material for wire and cable

[0074] 1. Material formula

[0075] components parts by weight Loose polyvinyl chloride resin - high degree of polymerization polyvinyl chloride resin, degree of polymerization

2000~3000 110 Plasticizer—TOPM plasticizer, flash point ≥ 260°C 25 Plasticizer - adipic acid polyester plasticizer, molecular weight 3000-4000 30 Calcium zinc stabilizer - 105 ℃ ~ 125 ℃ grade high temperature calcium zinc stabilizer 15 Antioxidant 1076 0.9 Flame Retardant - Aluminum Hydroxide 8 Filler - Calcium Carbonate 20 Lubricant - Magnesium Stearate 0.8 Processing Modifier—ACR201 1.2

[0076] 2. Preparation process

[0077] Same as embodiment one.

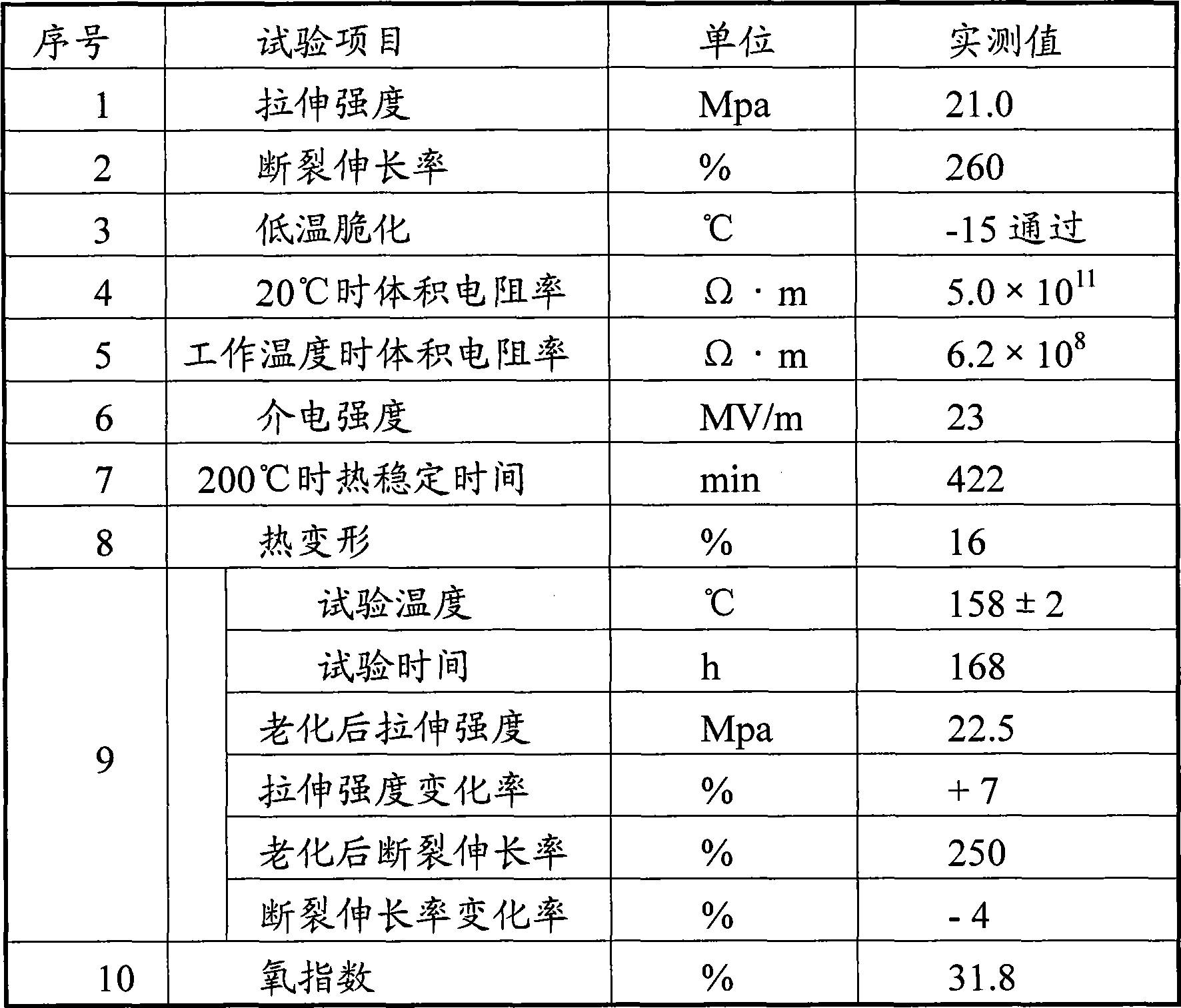

[0078] 3. Technical indicators

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com