A kind of manufacture method of non-stick coating

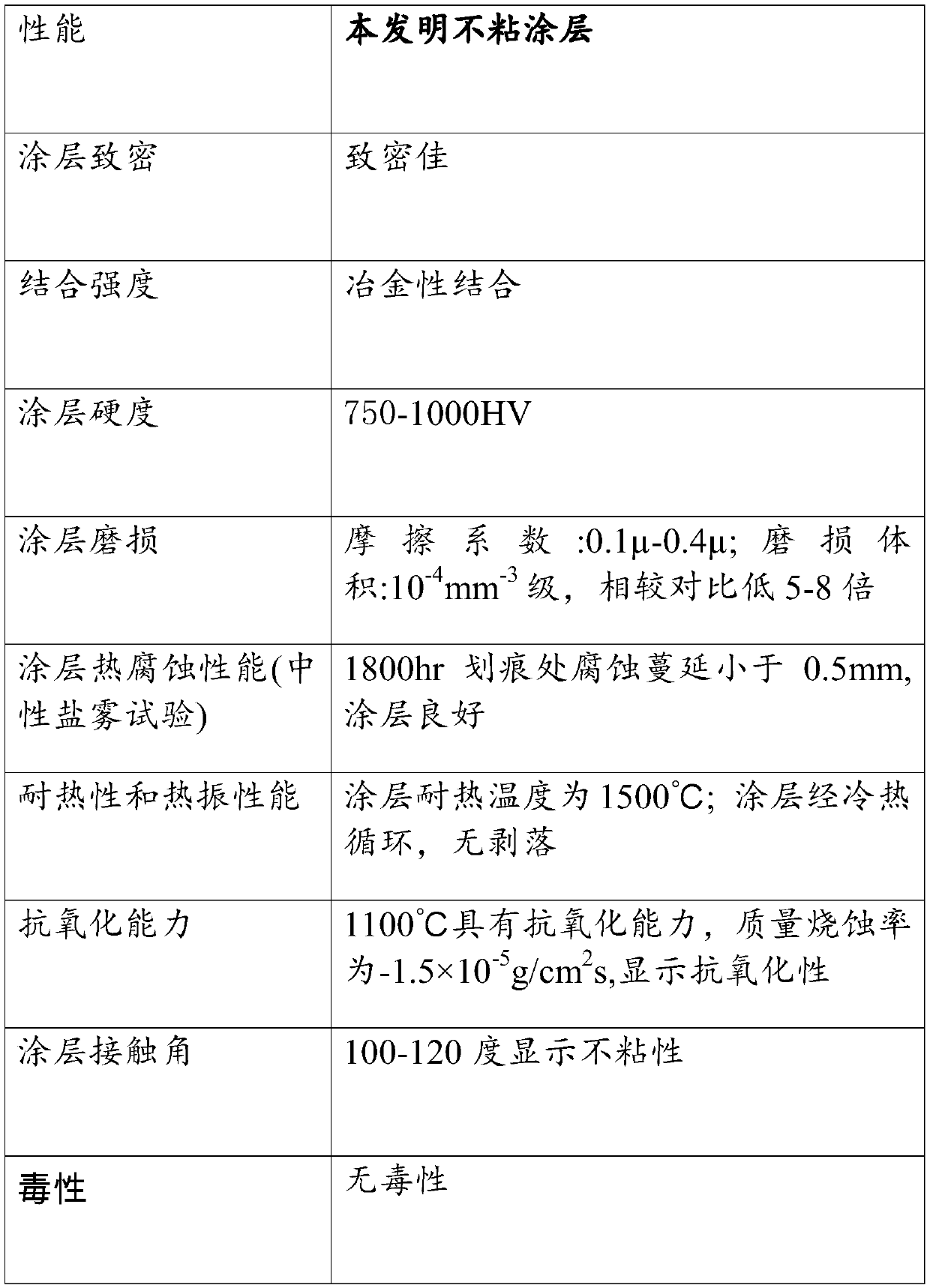

A technology of non-stick coating and production method, which is applied in coating, manufacturing tools, fireproof coating, etc., can solve the problems of not being able to make acidic food, affecting the performance of the pot body, and easy loss of heat, etc., and achieves good chemical stability and porosity Less, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method of making a non-stick coating, comprising the following steps:

[0032] 1. Pre-treat the inner surface of the pot to remove dust, grease and rust;

[0033] 2. Preheat the inner surface of the pot to 100℃;

[0034] 3. Using the plasma spraying system, the powder material of the base layer is preset on the inner surface of the pot by the method of plasma spraying powder, and then the base layer is obtained by electron beam welding; in the same way, the powder material of the first transition layer and the powder material of the second layer are preset layer by layer. transition layer powder material and surface layer powder material to obtain a first transition layer, a second transition layer and a surface layer;

[0035] The process parameters of the plasma spray powder are as follows: the angle of the spray gun: 45-90 degrees, the current is 400-800A, the distance between the nozzle of the spray gun and the inner surface of the container is 10-70cm, the movin...

Embodiment 2

[0039] A method of making a non-stick coating, comprising the following steps:

[0040] 1. Pre-treat the inner surface of the pot to remove dust, grease and rust;

[0041] 2. Preheat the inner surface of the pot to 200℃;

[0042] 3. Using the plasma spraying system, the powder material of the base layer is preset on the inner surface of the pot by the method of plasma spraying powder, and then the base layer is obtained by electron beam welding; in the same way, the powder material of the first transition layer and the powder material of the second layer are preset layer by layer. transition layer powder material and surface layer powder material to obtain a first transition layer, a second transition layer and a surface layer;

[0043] The process parameters of plasma spraying are as follows: the angle of the spray gun: 45-90 degrees, the current is 400-800A, the distance between the nozzle of the spray gun and the inner surface of the container is 10-70cm, the moving speed ...

Embodiment 3

[0047] A method of making a non-stick coating, comprising the following steps:

[0048] 1. Pre-treat the inner surface of the pot to remove dust, grease and rust;

[0049] 2. Preheat the inner surface of the pot to 300℃;

[0050] 3. Using the plasma spraying system, the powder material of the base layer is preset on the inner surface of the pot by the method of plasma spraying powder, and then the base layer is obtained by electron beam welding; in the same way, the powder material of the first transition layer and the powder material of the second layer are preset layer by layer. transition layer powder material and surface layer powder material to obtain a first transition layer, a second transition layer and a surface layer;

[0051] The process parameters of the plasma spray powder are as follows: the angle of the spray gun: 45-90 degrees, the current is 400-800A, the distance between the nozzle of the spray gun and the inner surface of the container is 10-70cm, the movin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com