Electroslag remelting quaternary slag system for preparing high-purity stainless steel

A technology of electroslag remelting and quaternary slag, applied in the field of electroslag, can solve the problems affecting the internal quality of military products and difficult to meet the requirements of technical indicators, so as to reduce the content of non-metallic inclusions, low use cost, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using the quaternary slag system of the present invention to prepare high-purity 12% Cr stainless steel electroslag remelting steel ingots comprises the following steps:

[0019] The first step, the preparation of metal electrodes:

[0020] The source of metal electrodes is the key to whether the electroslag furnace can be produced. In this embodiment, metal electrodes of various specifications for electroslag remelting are obtained by using "electric arc furnace + refining outside the furnace" smelting, and using the down casting method, and the electrode specifications are 1.1 to 1.3 tons per piece;

[0021] a. The chemical composition and weight percentage composition of consumable electrodes should meet the following requirements:

[0022] C 0.08~0.15%, Mn 0.50~0.90%, Si≤0.25%, S≤0.015%, P≤0.020%, Ni 2.00~3.00%, Cr 11.00~12.50%, Mo 1.50~2.00%, V 0.25~0.40% , N0.020~0.040%, the balance is Fe; residual element requirements: Ti≤0.020%, Al≤0.020%, Cu≤0.10%, Sn≤0.015%,...

Embodiment 2~6

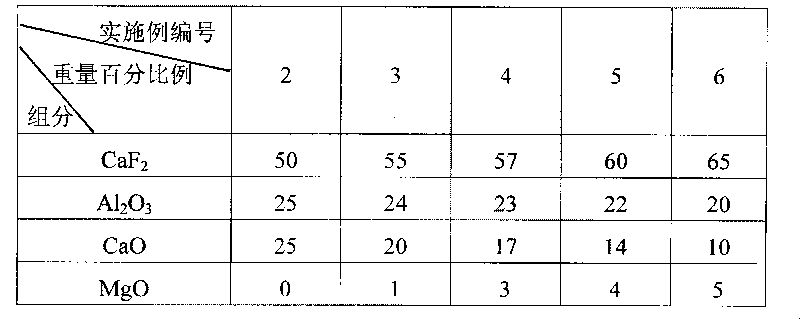

[0034] The quaternary slag system of the present invention is used to prepare high-purity 12% Cr stainless steel electroslag remelting steel ingots, and the slag composition and weight percentage examples of the quaternary slag system are shown in the following table:

[0035]

[0036] Others are the same as those described in Embodiment 1 or the contents of the present invention, omitted.

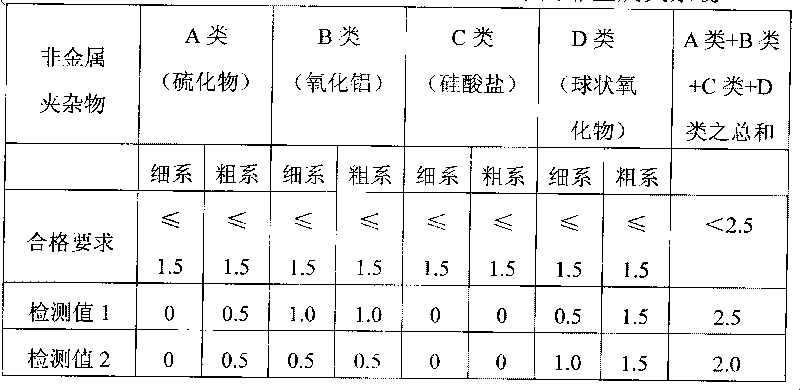

[0037] Adopt the method described in the embodiment of the present invention 1 or the content of the present invention part, the super (super) critical material 1Cr12Ni3Mo2VN steel [steam turbine super (super) critical material] of production, detect the data of the nonmetallic inclusion of super (super) critical material See Table 1:

[0038] Table 1: Non-metallic inclusions in super(super)critical material 1Cr12Ni3Mo2VN steel

[0039]

[0040] Note: 1. The value of "Qualified Requirements" in Table 1 is the value required by the enterprise standard, and the inspection method is ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com