Preparation method of refractory castable

A technology for refractory castables and raw materials, applied in the field of castables, can solve problems such as poor resistance to penetration of molten aluminum and inability to meet market demands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

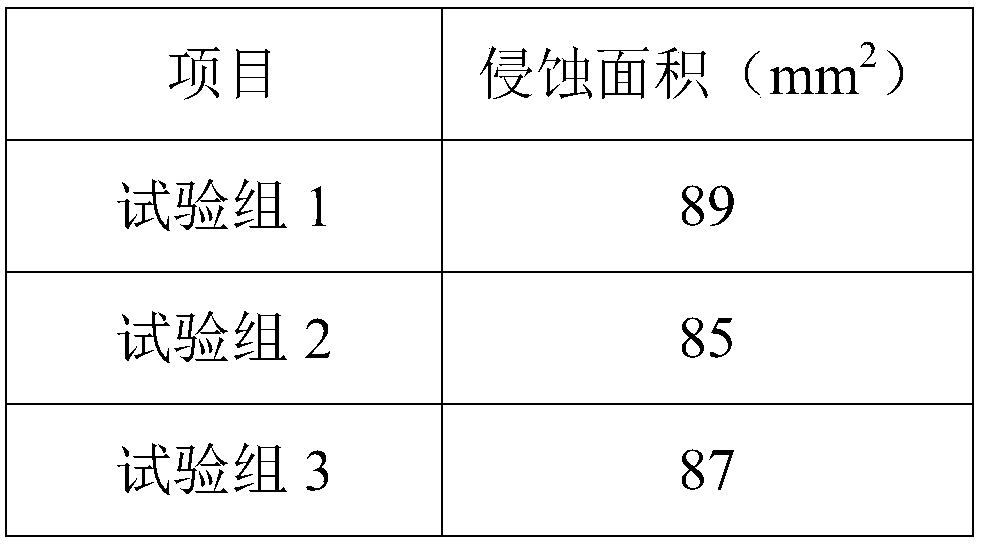

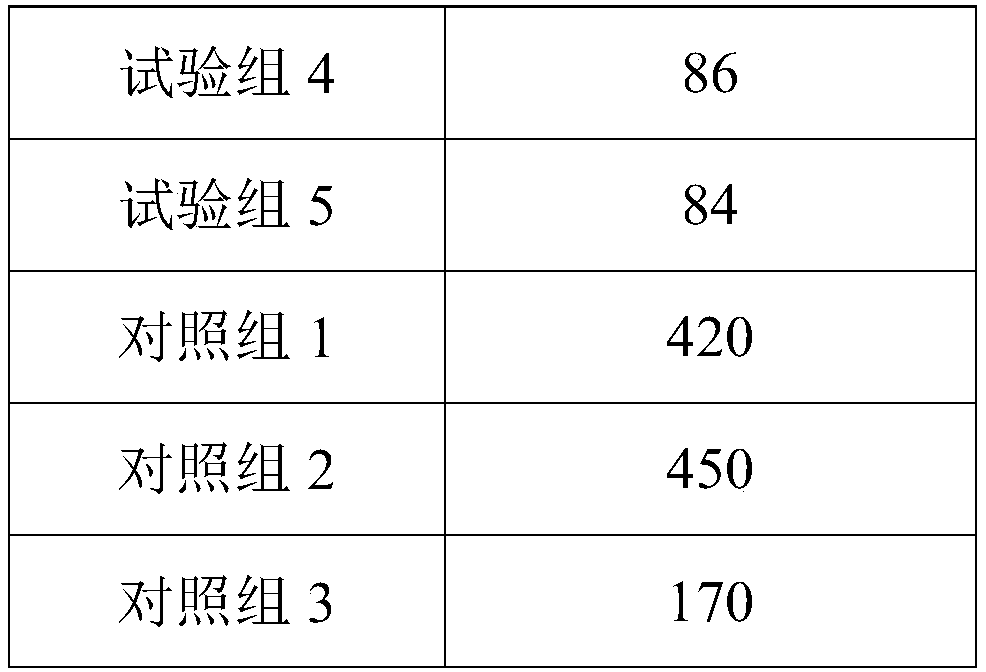

Examples

Embodiment 1

[0016] A method for preparing a refractory castable, the raw material composition and weight ratio of the refractory castable are: 55 parts of brown corundum, 19 parts of kyanite powder, 2 parts of feldspar powder, 11.5 parts of calcium aluminate cement, and 3 parts of calcium sulfate , 9.5 parts of calcium fluoride, 1.5 parts of anti-seepage aid, 9 parts of explosion-proof fiber, 1.5 parts of dispersant, 14 parts of sodium silicate, 2.5 parts of potassium silicate, 0.5 part of rare earth; during preparation, according to the weight ratio, first Co-grind brown corundum, calcium sulfate, calcium fluoride and anti-seepage additives in a vibration mill for 45 minutes to obtain homogenized powder, then mix the homogenized powder with other components and knead evenly to obtain a refractory castable.

Embodiment 2

[0018] A method for preparing a refractory castable, the raw material composition and weight ratio of the refractory castable are: 78 parts of brown corundum, 12 parts of kyanite powder, 7 parts of feldspar powder, 5 parts of calcium aluminate cement, and 8.5 parts of calcium sulfate , 2 parts of calcium fluoride, 4.5 parts of anti-seepage aid, 4.5 parts of explosion-proof fiber, 4 parts of dispersant, 6 parts of sodium silicate, 7.5 parts of potassium silicate, 0.1 part of rare earth; during preparation, according to the weight ratio, first Co-grind brown corundum, calcium sulfate, calcium fluoride and anti-seepage additives in a vibration mill for 55 minutes; obtain homogenized powder, then mix the homogenized powder with other components, and knead evenly to obtain a refractory castable;

[0019] Wherein, the preparation method of the anti-seepage auxiliary agent is as follows: taking iron powder and chromium nitride powder and mixing uniformly, sintering treatment, and heat...

Embodiment 3

[0021] A method for preparing a refractory castable, the raw material composition and weight ratio of the refractory castable are: 65 parts of brown corundum, 15 parts of kyanite powder, 4 parts of feldspar powder, 9 parts of calcium aluminate cement, and 5 parts of calcium sulfate , 6 parts of calcium fluoride, 3 parts of anti-seepage auxiliary agent, 7 parts of explosion-proof fiber, 3 parts of dispersant, 9 parts of sodium silicate, 5 parts of potassium silicate, 0.3 part of rare earth; during preparation, according to the weight ratio, first Co-grind brown corundum, calcium sulfate, calcium fluoride and anti-seepage additives in a vibrating mill for 50 minutes; obtain homogenized powder, then mix the homogenized powder with other components, and knead evenly to obtain a refractory castable;

[0022] Wherein, the preparation method of the anti-seepage additive is: take iron powder and chromium nitride powder and mix uniformly according to the mass ratio of 1:1.5, sinter at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com