Preparation method of hydrophobic micro-arc oxidation bioactive coating with titanium surface

A technology of micro-arc oxidation and biological coating, which is applied in the direction of surface reaction electrolytic coatings, coatings, electrolytic coatings, etc., can solve the problems of micro-arc oxidation coatings being easily corroded, coating biological activity failure, etc., to facilitate the industry The effect of modernized production, simple and easy method, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

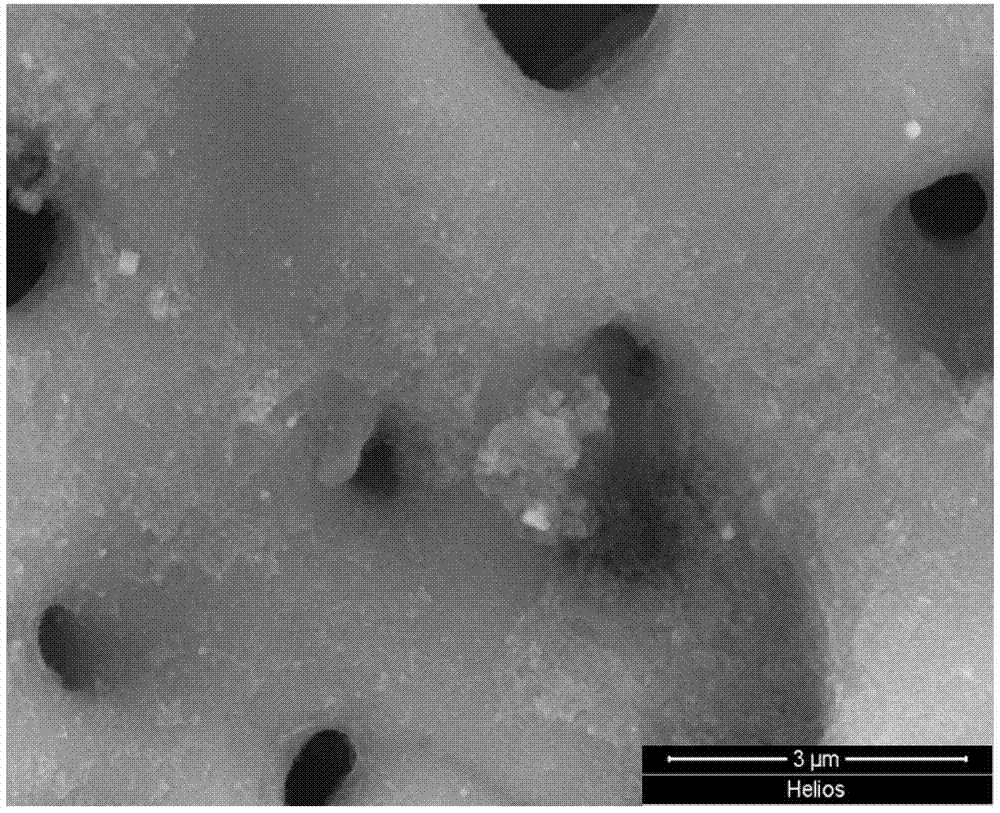

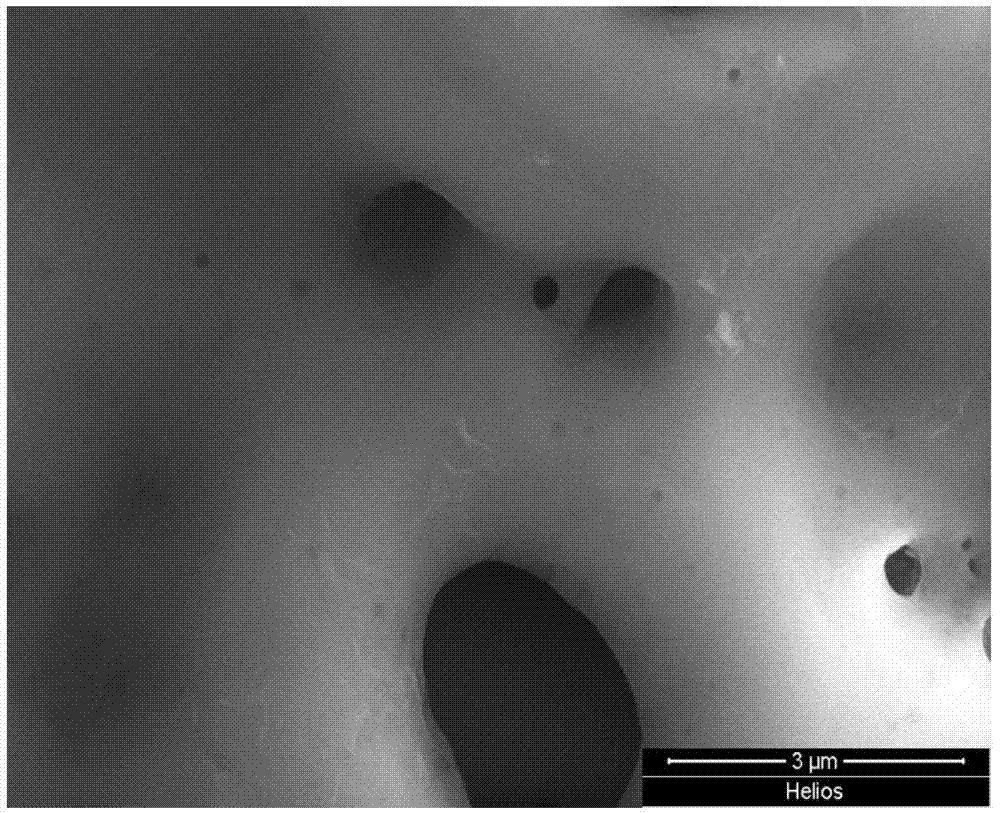

[0017] Specific embodiment one: the preparation method of a kind of hydrophobic micro-arc oxidation biological coating on the surface of titanium according to the present embodiment is carried out according to the following steps:

[0018] 1. Titanium sample surface pretreatment: use 200#, 600#, 1000# and 1500# sandpaper to polish the titanium sample in sequence, and then use acetone, 95% ethanol solution and deionized water in sequence Ultrasonic cleaning for 5 minutes, and then drying in a 40°C oven for 30 minutes;

[0019] 2. Prepare the micro-arc oxidation electrolyte: use deionized water as the solvent to prepare the micro-arc oxidation electrolyte. Sodium silicate solution, calcium acetate solution with a concentration of 1~19g / L, calcium dihydrogen phosphate solution with a concentration of 2~15g / L, EDTA-2Na solution with a concentration of 5~30g / L and a concentration of 0.1~20g / L The sodium hydroxide solution of L is formed;

[0020] 3. Put the titanium sample pretre...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the micro-arc oxidation electrolytic solution described in step 2 takes deionized water as a solvent, and is a silver acetate solution with a concentration of 10 ~ 25g / L, with a concentration of 5~10g / L sodium silicate solution, 5~10g / L calcium dihydrogen phosphate solution, 5~15g / L calcium acetate solution, 10~20g / L EDTA-2Na solution and Sodium hydroxide solution with a concentration of 10~20g / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the micro-arc oxidation electrolyte described in step two uses deionized water as a solvent, and the concentration is 15 ~ 20g / L silver acetate solution , a sodium silicate solution with a concentration of 7.1g / L, a calcium dihydrogen phosphate solution with a concentration of 6.3g / L, a calcium acetate solution with a concentration of 8.8g / L, an EDTA-2Na solution with a concentration of 15g / L and a concentration of 15g / L sodium hydroxide solution. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com