Carbon nano-reinforced aluminum-based conductor material and preparation method

A technology for strengthening aluminum-based and conductor materials, applied in the field of nano-phase-reinforced aluminum-based composite materials, can solve the problems of insufficient strength and heat resistance, and achieve the effects of high production efficiency, preventing crack propagation, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

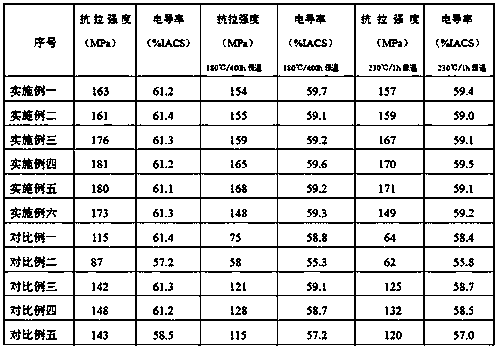

Examples

Embodiment 1

[0028] Alloy composition: graphene 0.07%, Zr 0.30%, Fe 0.008%, Si 0.038%, Ti 0.010%, and the balance is Al. Among them, the preparation process and proportion of redox graphene@silicon dioxide are as follows: prepare KH-550 silane coupling agent solution, ethanol: water ratio is 1:14, and the content of KH-550 in the solution is 1.5vol.%. Static hydrolysis for 6 hours; the graphene in the solution is no more than 5 layers, graphene oxide with an average particle size of 5 microns, so that the graphene concentration is 1.0g / L, then add silica powder and ultrasonically treat for 100min, nano-silica The particle size of the powder is 10nm, and the amount of silica added is 1.0% of the graphene mass. After the solution is vacuum freeze-dried, the graphene oxide is reduced and sintered. The sintering temperature is 1500°C and the time is 2h, and the reduced graphene oxide@silica is obtained. Composite powder. Clean the furnace before starting the furnace. If alloys other than 1 se...

Embodiment 2

[0030]Alloy composition: graphene 0.01%, Zr 0.1%, Ti 0.010%, Fe 0.071%, Si 0.035, each of the other elements ≤ 0.01%, and the balance is Al. The preparation process and proportion of pre-synthesized redox graphene@silica are as follows: prepare KH-550 silane coupling agent solution, ethanol: water is 10:4, KH-550 content in the solution is 1.2vol.%, static hydrolysis 6 hours; Add no more than 3 layers of graphene oxide with an average particle size of 20 microns in the solution to make the graphene concentration 1.0g / L, then add silicon dioxide and ultrasonically treat it for 120min, and the particle size of nano-silica powder is 50nm , the addition amount is 5% of the mass of graphene, after the solution is vacuum freeze-dried, the graphene oxide is reduced and sintered, the sintering temperature is 1500°C, and the time is 2h, to obtain the reduced graphene oxide@silicon dioxide composite powder. Clean the furnace before starting the furnace. If alloys other than 1 series wer...

Embodiment 3

[0032] Alloy composition: graphene 0.05%, Zr 0.15%, Ti 0.010%, Fe 0.069%, Si 0.034, each of the other elements ≤ 0.01%, and the balance is Al. The preparation process and proportion of pre-synthesized redox graphene@silicon dioxide are as follows: prepare KH-550 silane coupling agent solution, ethanol: water is 3:9, and the content of KH-550 in the solution is 1.0vol.%. Static hydrolysis for 4 hours; add no more than 3 layers of graphene oxide with an average particle size of 15 microns in the solution to make the graphene concentration 0.8g / L, then add silica powder and ultrasonically treat for 60 minutes, nano-silica powder The diameter is 10nm, and the amount added is 5% of the mass of graphene. After the solution is vacuum freeze-dried, graphene oxide is reduced and sintered at 1200°C for 4 hours to obtain reduced graphene oxide@silicon dioxide composite powder. Clean the furnace before starting the furnace. If alloys other than 1 series have been produced before, it is ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com