Preparation process of chemical plating rare earth cerium Ni-P-PTFE (Polytetrafluoroethylene) composite coating

A composite coating, rare earth cerium technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem of uneven PTFE coating, achieve low cost, good self-lubricating effect, improve wear resistance and The effect of antifouling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

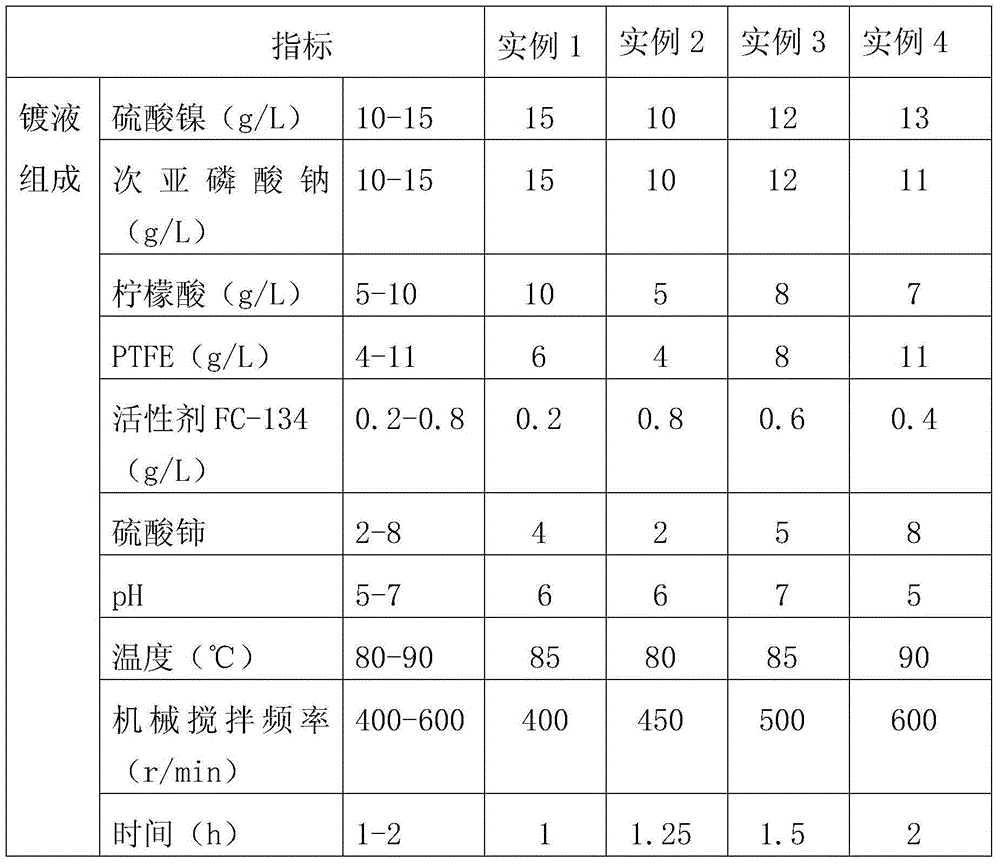

Embodiment 1

[0027] The bath configuration:

[0028] Plating: nickel sulfate 15g / L, sodium hypophosphite 15g / L, citric acid 10g / L, activator 0.2g / L, PTFE emulsion 6g / L, cerium sulfate 4g / L, pH 6, temperature 85°C, Time 1h; mechanical stirring: 400r / min;

Embodiment 2

[0030] The bath configuration:

[0031] Plating: nickel sulfate 10g / L, sodium hypophosphite 10g / L, citric acid 5g / L, activator 0.8g / L, PTFE emulsion 4g / L, cerium sulfate 2g / L, pH 6.0, temperature 80℃, Time 1.25h, mechanical stirring: 450r / min;

Embodiment 3

[0033] The bath configuration:

[0034] Plating: nickel sulfate 12g / L, sodium hypophosphite 12g / L, citric acid 8g / L, activator 0.6g / L, PTFE emulsion 8g / L, cerium sulfate 5g / L, pH 7, temperature 85℃, Time 1.5h; mechanical stirring: 500r / min;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com