Non-asphalt-based pre-paved waterproof coiled material with high water soaking resistance and preparation method of non-asphalt-based pre-paved waterproof coiled material

A non-bitumen-based, waterproof membrane technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, film/sheet adhesives, etc., can solve the bonding strength and skin-type waterproof effect impact, the isolation sand is easy to fall off, and the lap joints are easy to warp, etc., to achieve the effects of excellent peel strength, reduced water absorption, and improved wetting angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

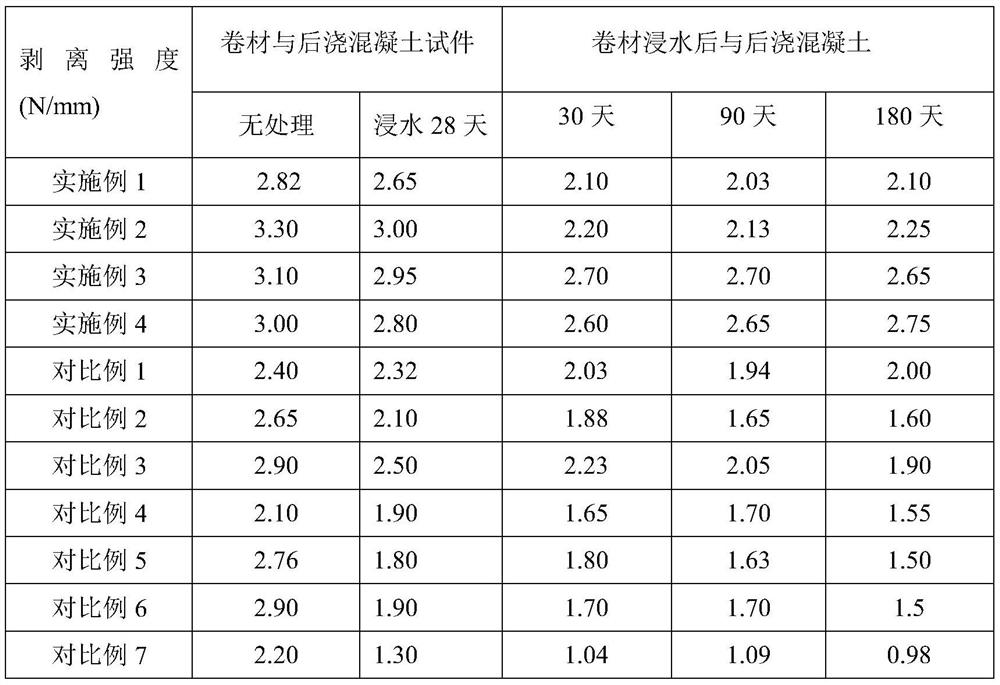

Embodiment 1

[0046]A high water-immersion non-ortel-based preparation waterproof web, including a polymer sheet substrate, a polar thermal molten sensitive glue coated on a substrate and a strong waterborne isolation sand covering on a rubber layer.

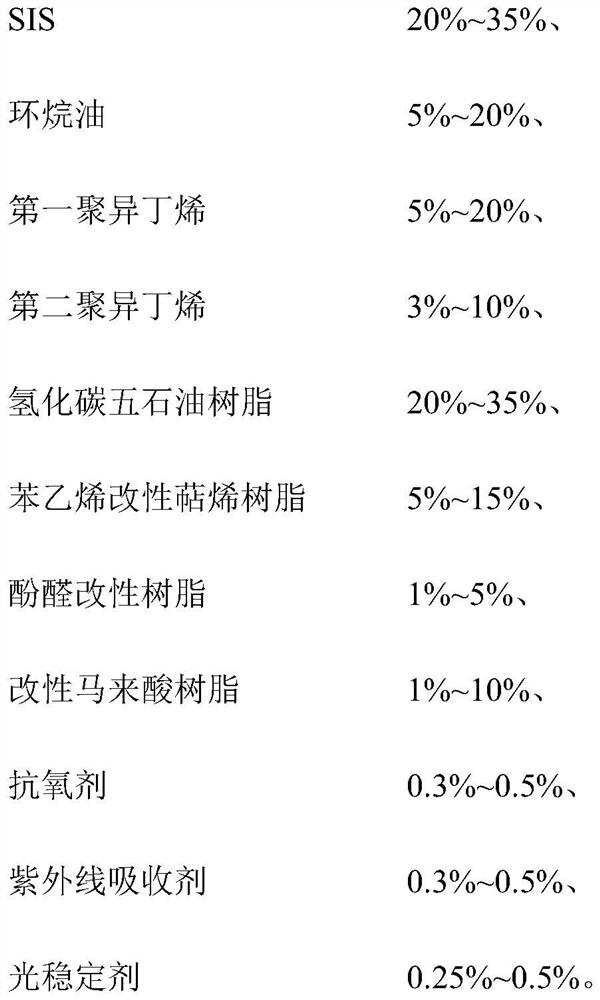

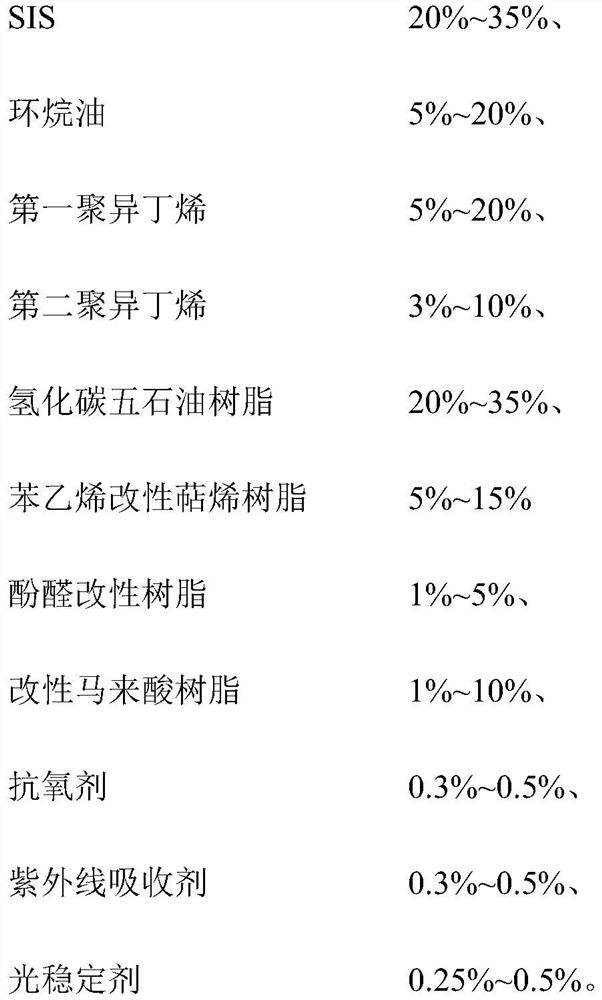

[0047]Further, the polar pressure sensitive adhesive includes the following raw materials: SIS 30kg, a cycloalkyl oil 15 kg, a first polyisobutylene, 5 kg, a second polyisobutylene 5 kg, a hydrogenated carbon-free hydrogen resin 33kg, a styrene modified terpene resin 10 kg, Phenolic modified resin 2 kg, modified maleic acid resin 5 kg, antioxidant 0.4 kg, ultraviolet absorber 0.4 kg and light stabilizer 0.5 kg.

[0048]Preferably, the SIS is Yuehua 4016, wherein the polystyrene content is 18%, and the diblock content is 75%.

[0049]The first polyisobutylene is PIB1300, and the second polyisobutylene is HRD-350.

[0050]The softening point of the hydrogenated carbon-hydrazine resin is 102 ° C.

[0051]The styrene modified terpene resin is Arizonachemical SA 100, ...

Embodiment 2

[0073]A high water-immersion non-ortel-based preparation waterproof web, including a polymer sheet substrate, a polar thermal molten sensitive glue coated on a substrate and a strong waterborne isolation sand covering on a rubber layer.

[0074]Further, the polar pressure sensitive adhesive includes the following raw materials: SIS 30kg, a cycloalkylene oil 20 kg, a first polyisobutylene 15 kg, a second polyisobutylene 5 kg, a hydrogenated carbon five petroleum resin 30 kg, a styrene modified terpene resin 15 kg, Phenolic modified resin 6kg, modified maleic acid resin 6 kg, an antioxidant 0.4 kg, ultraviolet absorber 0.4 kg and light stabilizer 0.5 kg.

[0075]Preferably, the SIS is Yuehua 1126, wherein the polystyrene content is 16%, and the diblock content is 50%.

[0076]The first polyisobutene is a PIB 950, and the second polyisobutylene is HRD-450.

[0077]The softening point of the hydrogenated carbon-hydrazine resin is 106 ° C.

[0078]The styrene modified terpene resin is a Pinova HM106, a...

Embodiment 3

[0089]A high water-immersion non-ortel-based preparation waterproof web, including a polymer sheet substrate, a polar thermal molten sensitive glue coated on a substrate and a strong waterborne isolation sand covering on a rubber layer.

[0090]Further, the polar pressure-sensitive adhesive includes the following raw materials: SIS 28kg, a cycloalkyl oil 12 kg, a first polyisobutylene 21kg, a second polyisobutylene 6 kg, a hydride-hydrocarbon-free hydrogen resin 28 kg, a styrene modified terpene resin 10 kg, Phenolic modified resin 2 kg, modified maleic acid resin 5 kg, antioxidant 0.4 kg, ultraviolet absorber 0.4 kg and light stabilizer 0.6 kg.

[0091]Preferably, the SIS is Yuehua 4016, wherein the polystyrene content is 18%, and the diblock content is 75%.

[0092]The first polyisobutene is a PIB 1300, and the second polyisobutylene is HRD-350.

[0093]The softening point of the hydrogenated carbon-hydrazine resin is 102 ° C.

[0094]The styrene modified terpene resin is Arizonachemical SA 100,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com