Spiral type heating dryer with materials being loaded separately

A screw type, dryer technology, applied in dryers, non-progressive dryers, drying and other directions, can solve the problems of prolonging the residence time of the dryer, reducing the drying efficiency of the device, and low drying efficiency, and achieves wetting. The effect of large angle, high temperature hardness and low bubble rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

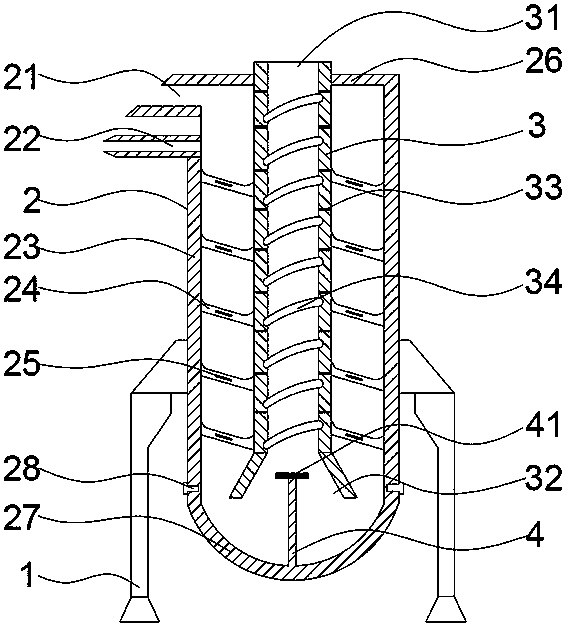

[0019] Such as figure 1 As shown, the spiral heating dryer for object packaging includes a support column 1, an outer drying cylinder 2 supported by the support column 1 and fixedly connected, and an outer drying cylinder 2 nested inside the outer drying cylinder 2 and arranged coaxially with the outer drying cylinder 2. The inner drying cylinder 3 has four support columns and is symmetrically distributed around the outer drying cylinder 2. The outer drying cylinder 2 includes an outer cylinder body 23 with upper and lower ends open, which is fixedly connected to the upper end of the outer cylinder body 23 and sealed. 23, the top cover 26 with the upper end open, the cylinder bottom 27 that is fixedly connected to the lower end of the outer cylinder 23 and seals the lower end opening of the outer cylinder 23, and the top end of the upper part of the side wall of the outer cylinder 23 is provided with a feed port 21 that runs through the side wall of the outer cylinder , the ho...

Embodiment 2

[0027] Such as figure 1 As shown, the spiral heating dryer for separate packaging of objects, after the power is turned on, the outer drying cylinder 2 is fixedly connected with support columns 1 for supporting this embodiment. The part is connected with the heater, and is used to transmit the hot air flow to the outer drying cylinder 2. Since the outer cylinder body 23 is provided with a spiral downward guide plate 24, when the wet material is added from the feed port 21, the wet material is in the hot air flow. Under the action, it moves downward in a spiral along the upper end surface of the guide plate 24, and is dried in the outer drying cylinder 2; There is a spiral upward airflow in the drying cylinder 3. When the material moves downward to the bottom 27 of the cylinder, the dried material is entrained by the airflow and is driven by the suction fan 41 and the air flow of the induced draft fan to move upward from the inner drying cylinder 3. After further drying, it is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com