Product containing NiCrN ternary coating and preparation method thereof

A product and coating technology, applied in the field of new PVD ternary coating, can solve the problems of coating application limitation, easy cracking, peeling, poor toughness, etc., and achieve the effect of improving the bonding strength of film base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Pretreatment of the base part: take He H13 mold steel as the product base part, ultrasonically clean the product base part in 10 g / L sodium hydroxide aqueous solution for 8 minutes, then ultrasonically clean it in acetone for 9 minutes, and finally clean it in absolute ethanol Ultrasonic cleaning for 8 minutes to obtain the pretreated product substrate.

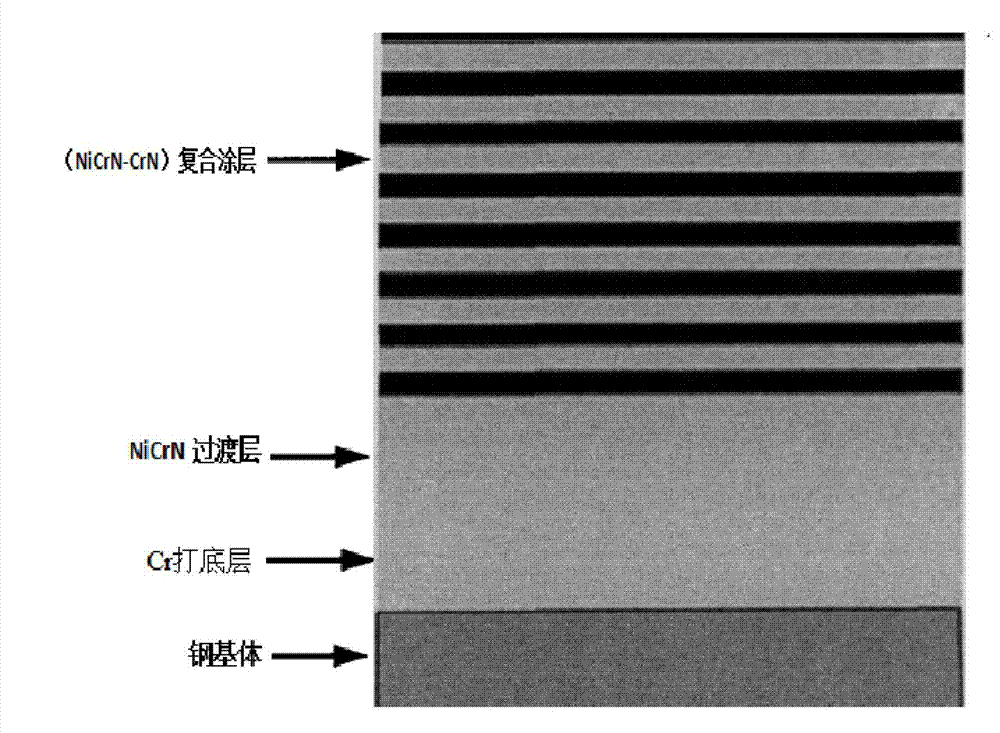

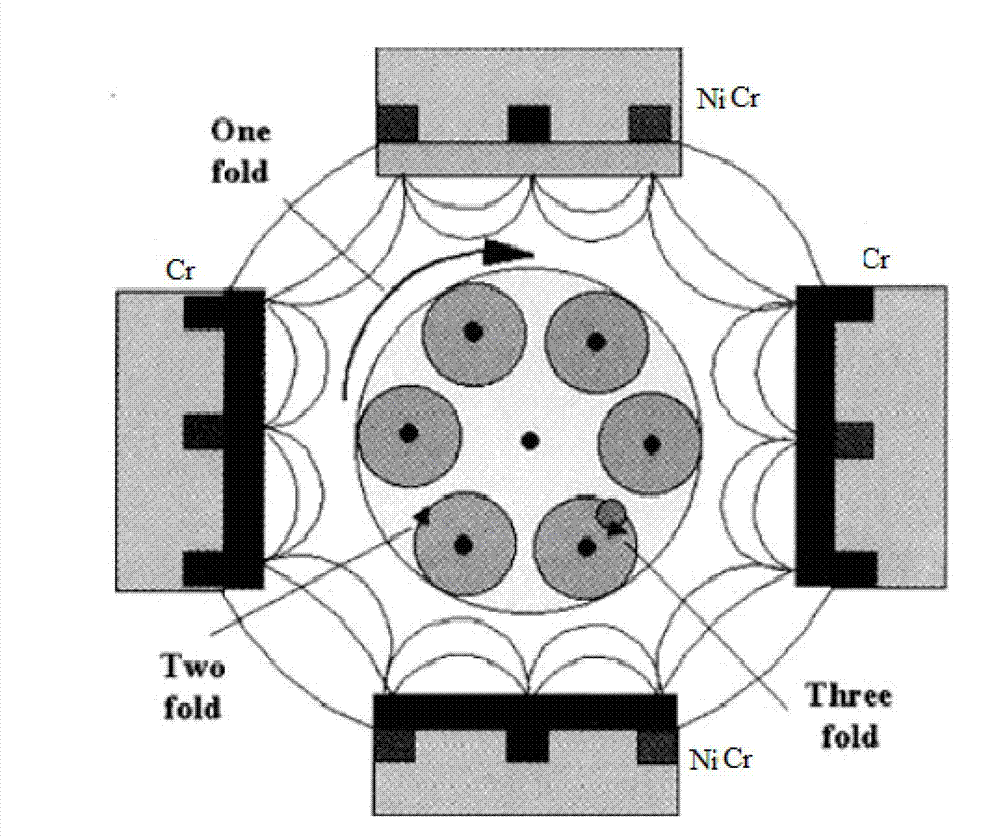

[0031] (2) The NiCrN ternary coating was prepared by Teer-UDP850 / 4 closed-field unbalanced magnetron sputtering ion plating equipment (see the schematic diagram of the coating structure in figure 1 shown) the main steps are as follows:

[0032] 1) Turn on the machine to preheat, pass cooling water, turn on the mechanical pump to vacuum to 4.0×10 -4 Pa, and heat the vacuum chamber to 100°C;

[0033] 2) Introduce argon gas, adjust the gas cylinder valve and flow meter, and adjust the air pressure in the vacuum chamber to make the target glow;

[0034] 3) Ion cleaning: rotate the substrate, adjust the bias voltage ...

Embodiment 2

[0045] The pretreated H13 die steel was nitriding at 570°C for 8 hours in a nitriding furnace, and then a NiCrN ternary coating was prepared using Teer-UDP850 / 4 closed-field unbalanced magnetron sputtering ion plating equipment. Other operations and methods are the same as in Example 1. The thickness of the NiCrN-CrN composite coating in the product is 3 μm, that is, the product containing the NiCrN ternary coating is obtained, and the product containing the NiCrN ternary coating is used as a sample for performance testing.

[0046] The VEGA-3-S scanning electron microscope produced by the Czech TESCAN company was used to observe the surface morphology of the sample, and the results are shown in Figure 4 shown. Figure 4 The nanocrystalline morphology of the NiCrN ternary coating surface is shown.

[0047] The HMV-1T microhardness tester was used to measure the microhardness value under a load of 10g, and the holding time was 10s. In order to reduce the error, measure the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com