Patents

Literature

37results about How to "Inhibition of decarburization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel wire material for spring and its producing method

InactiveUS20090020189A1Workability be deteriorateImprove hardenabilityFurnace typesHeat treatment process controlNickelTitanium

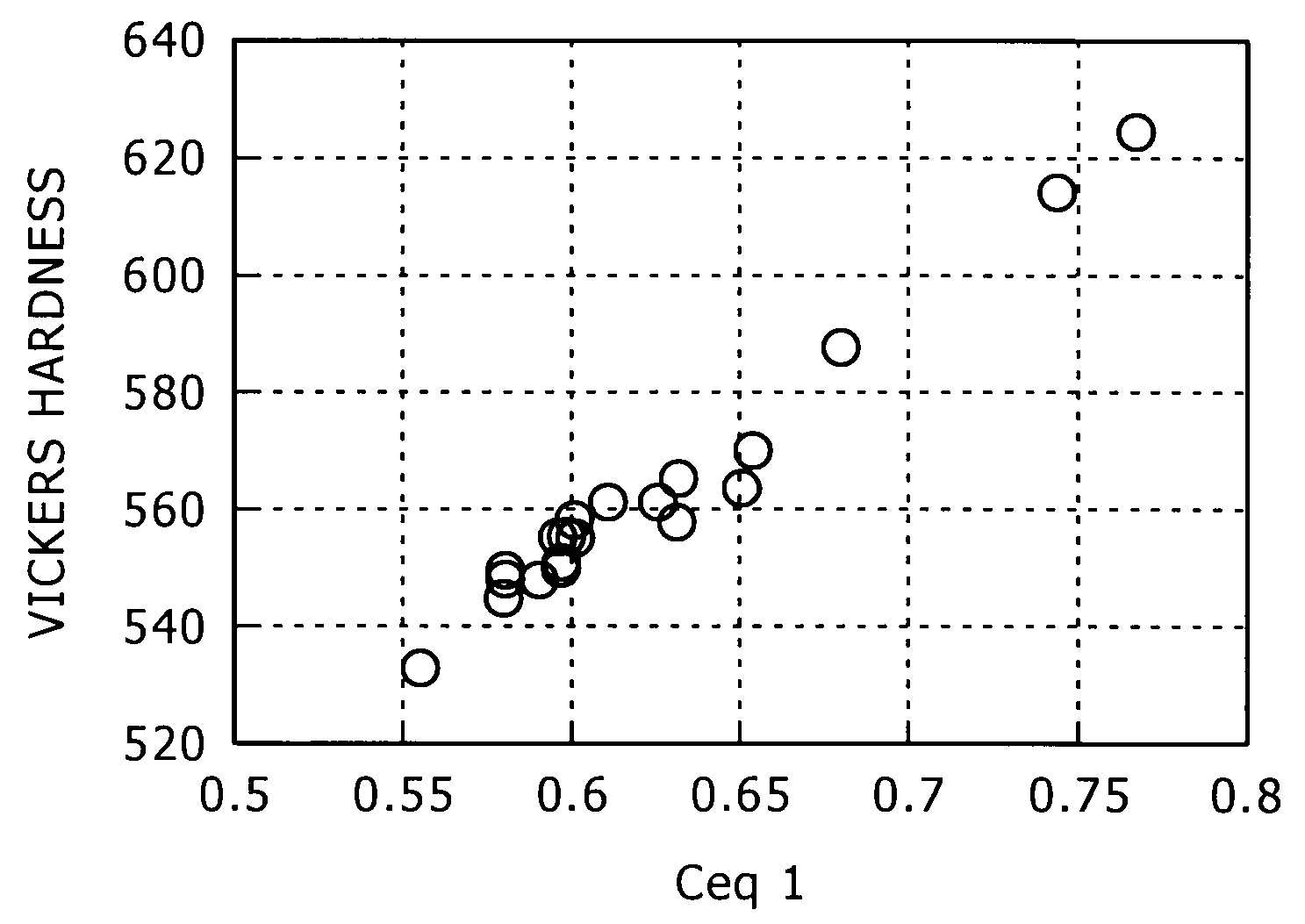

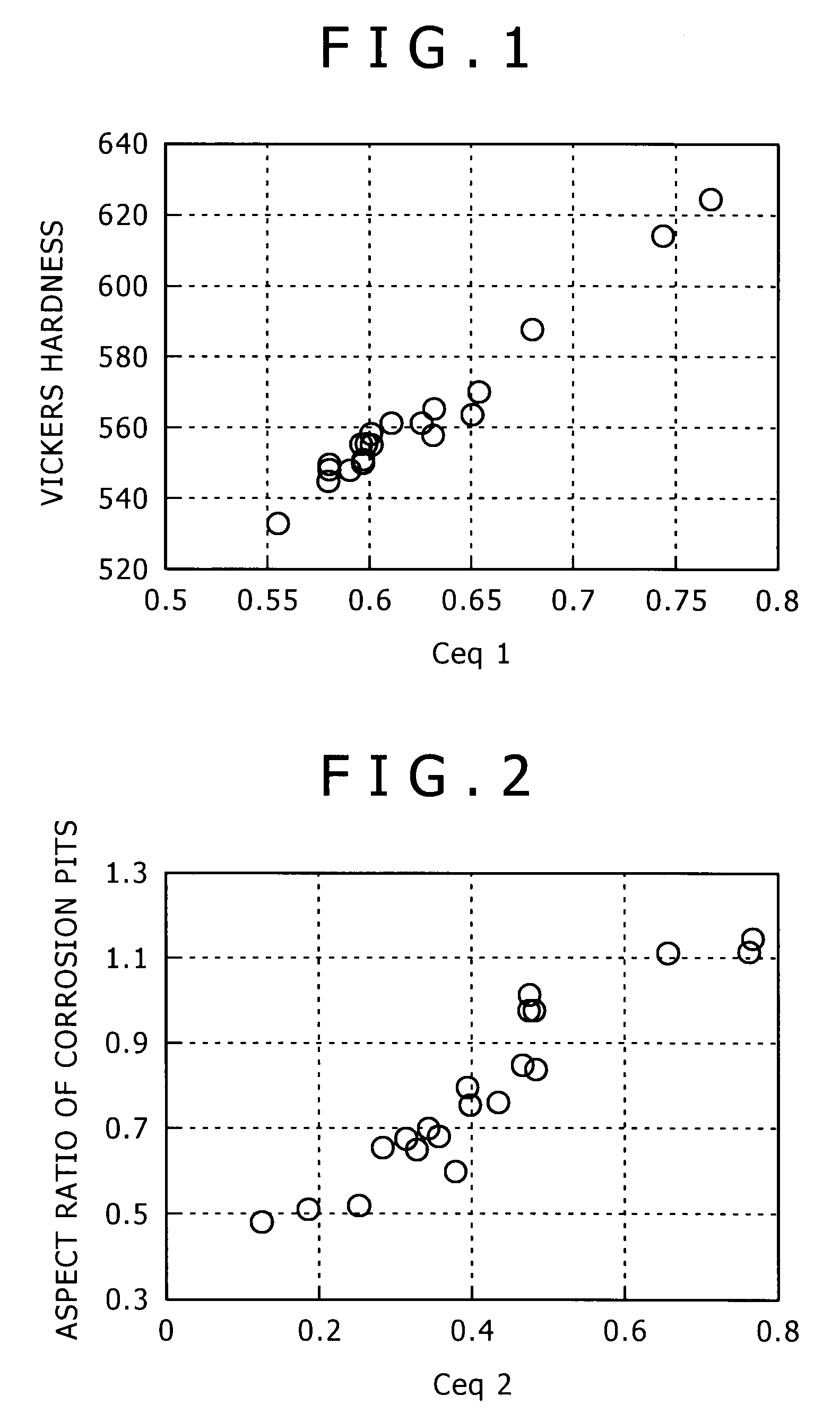

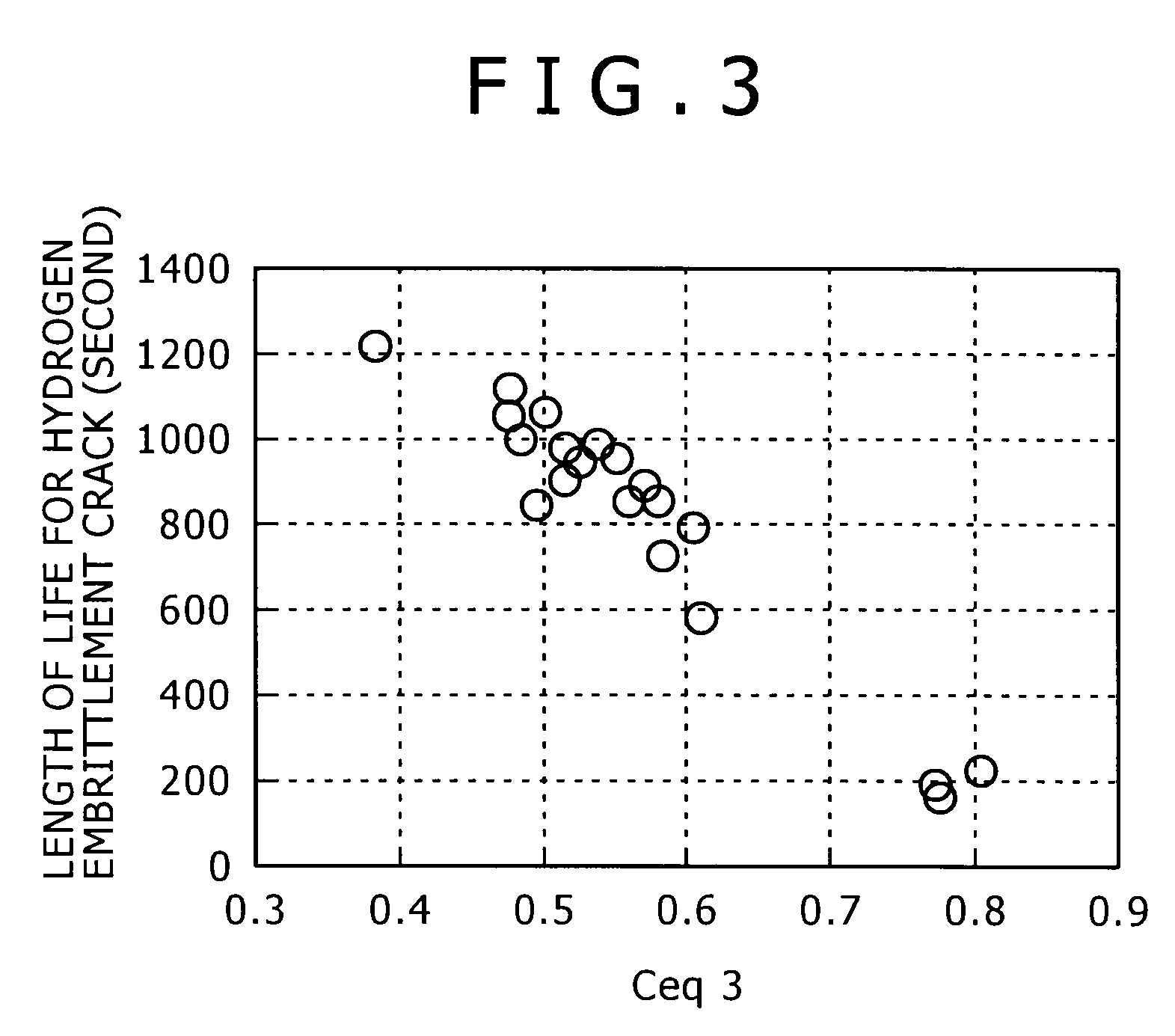

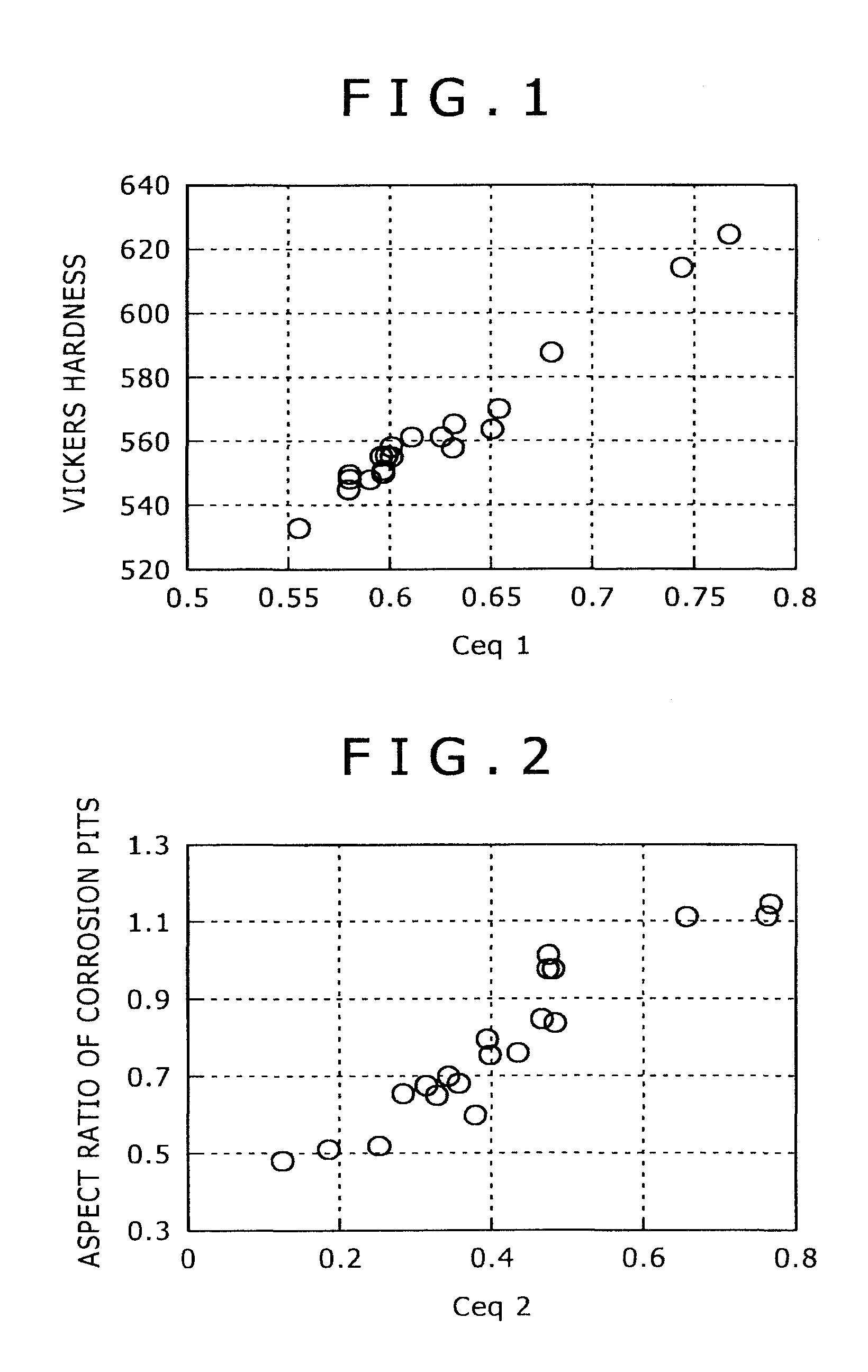

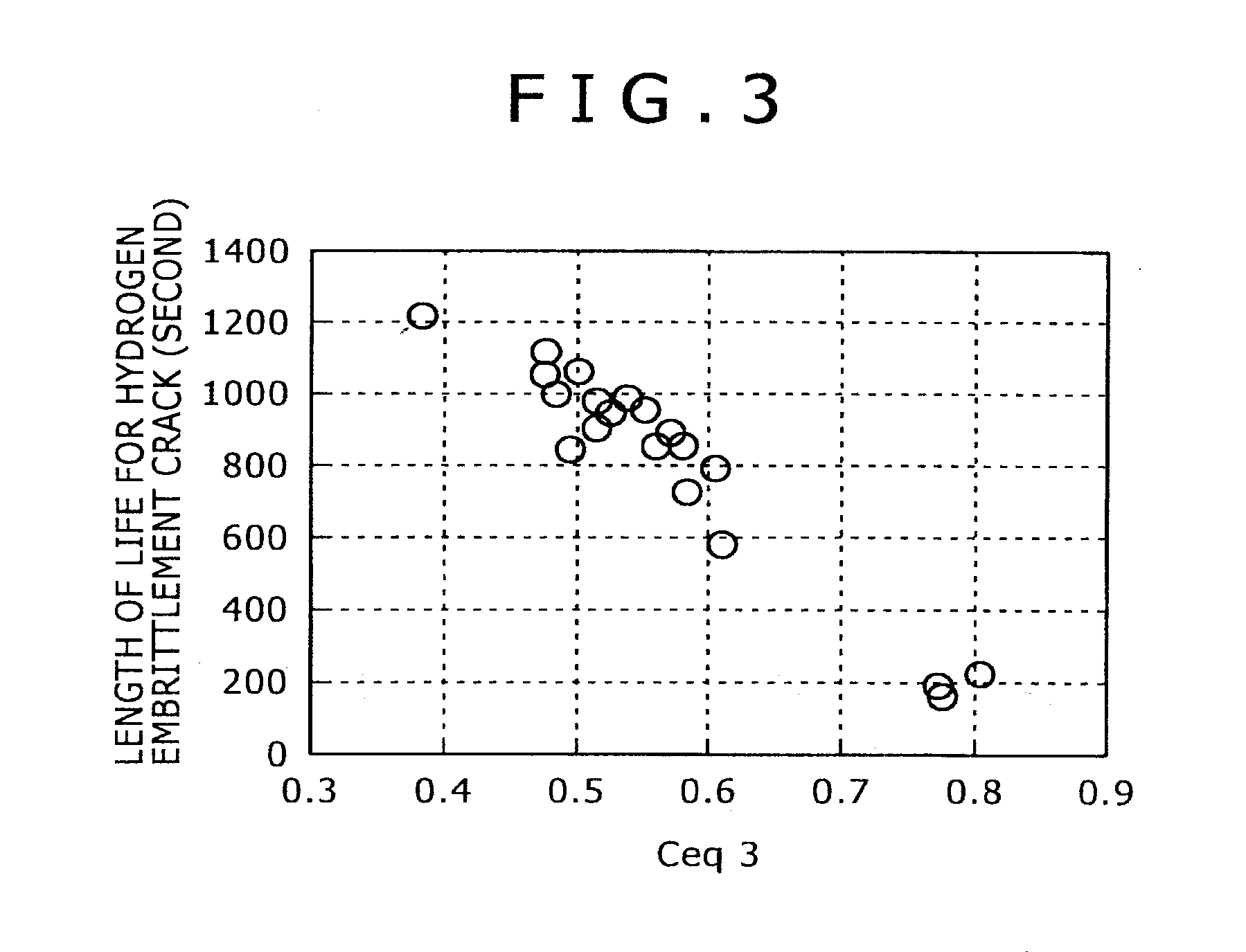

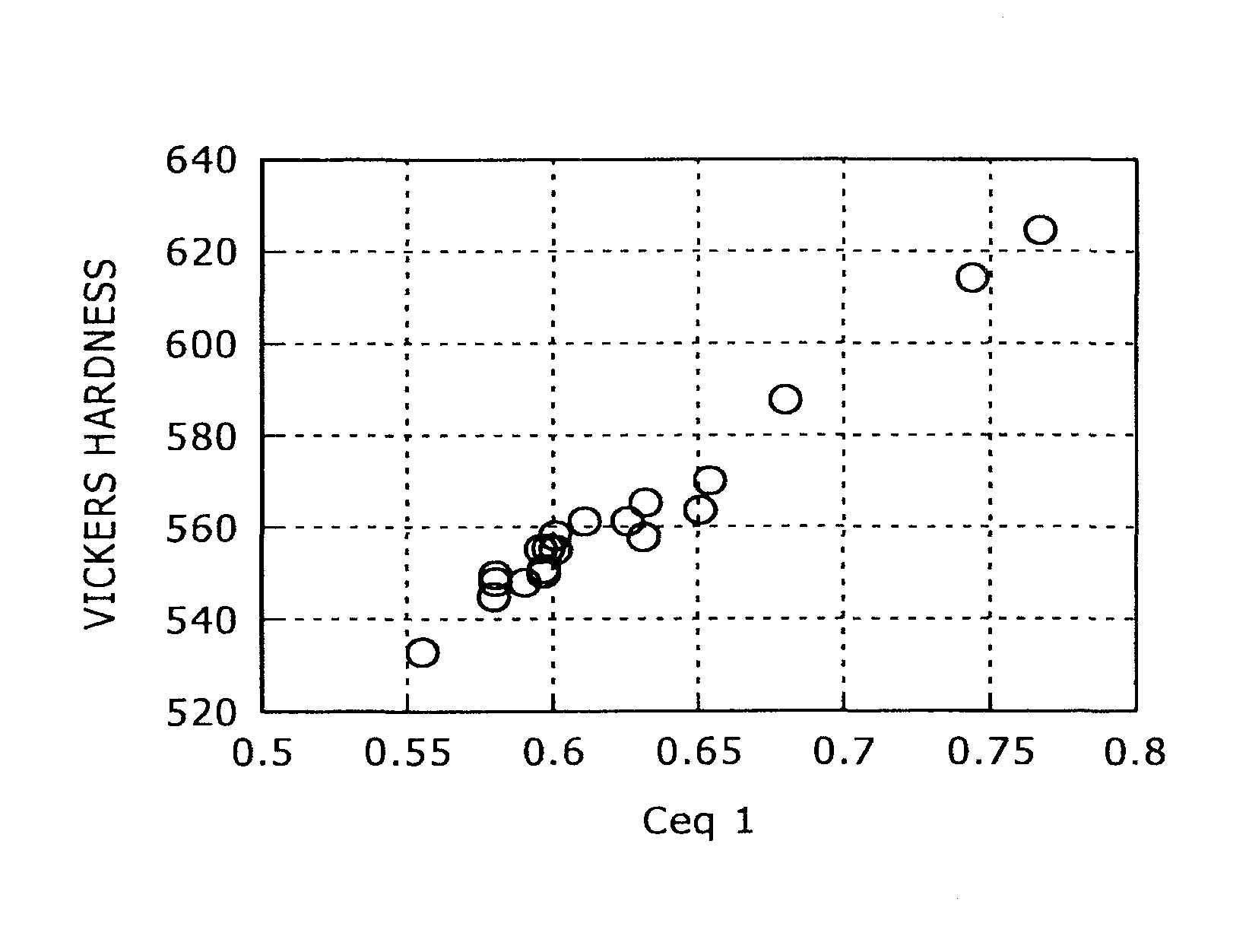

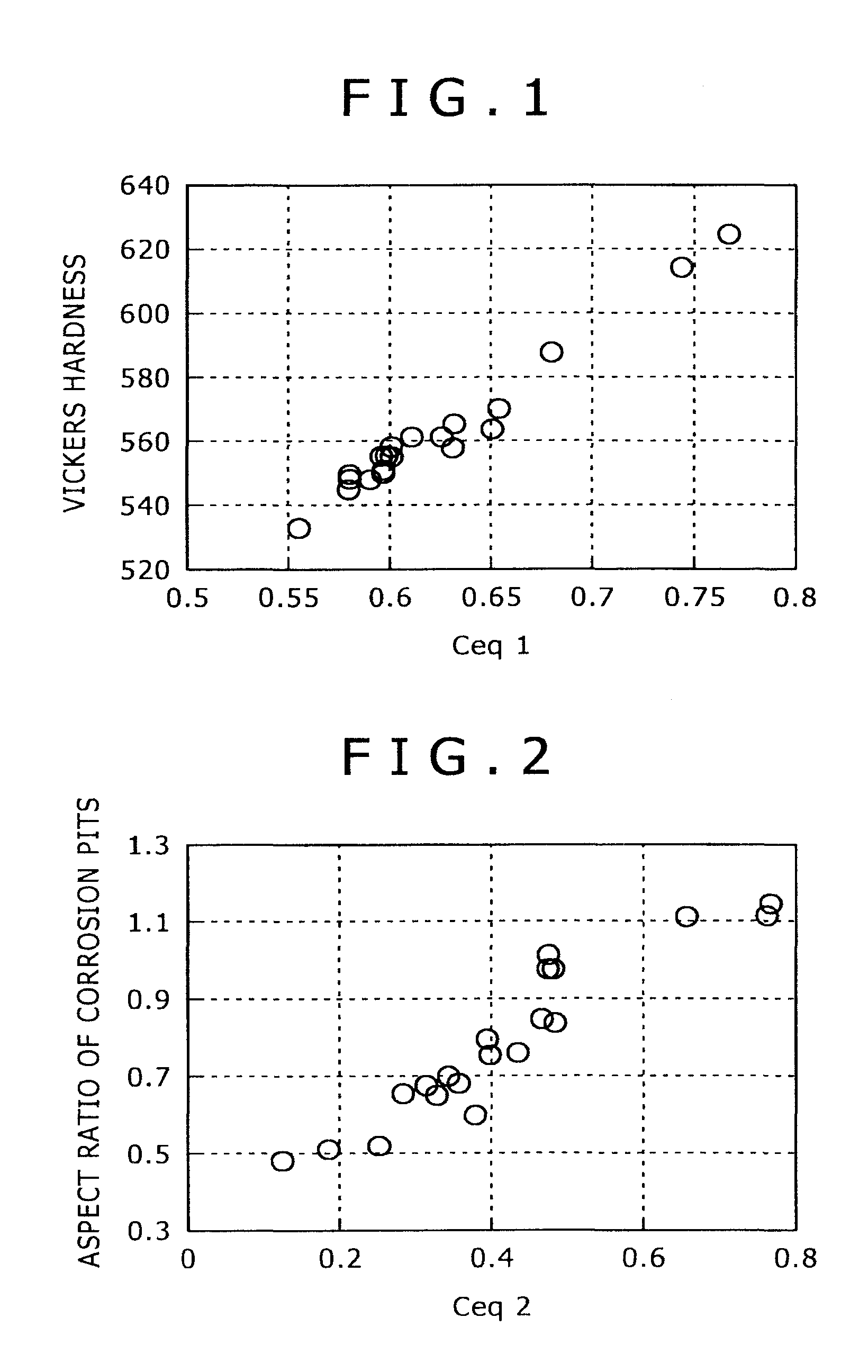

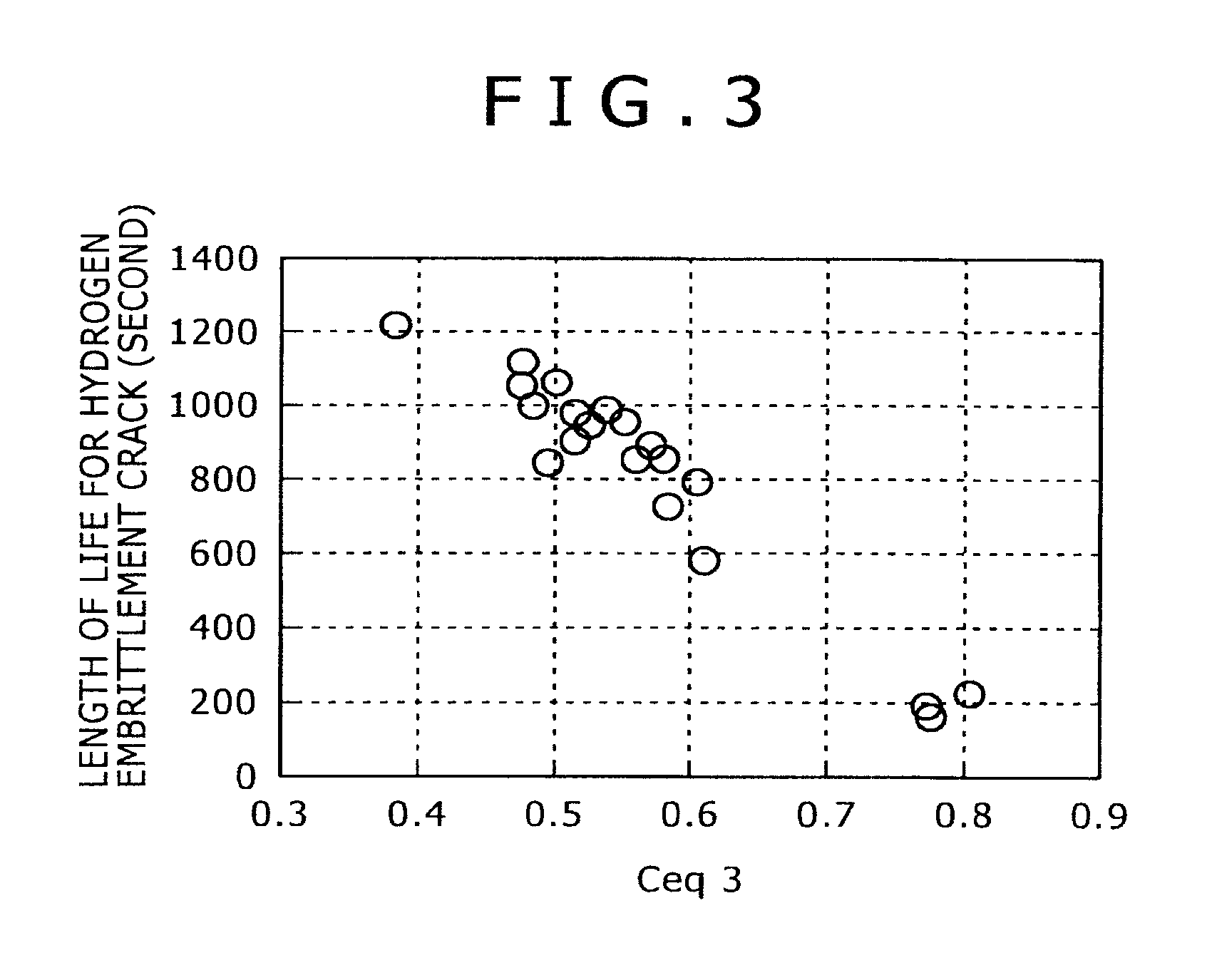

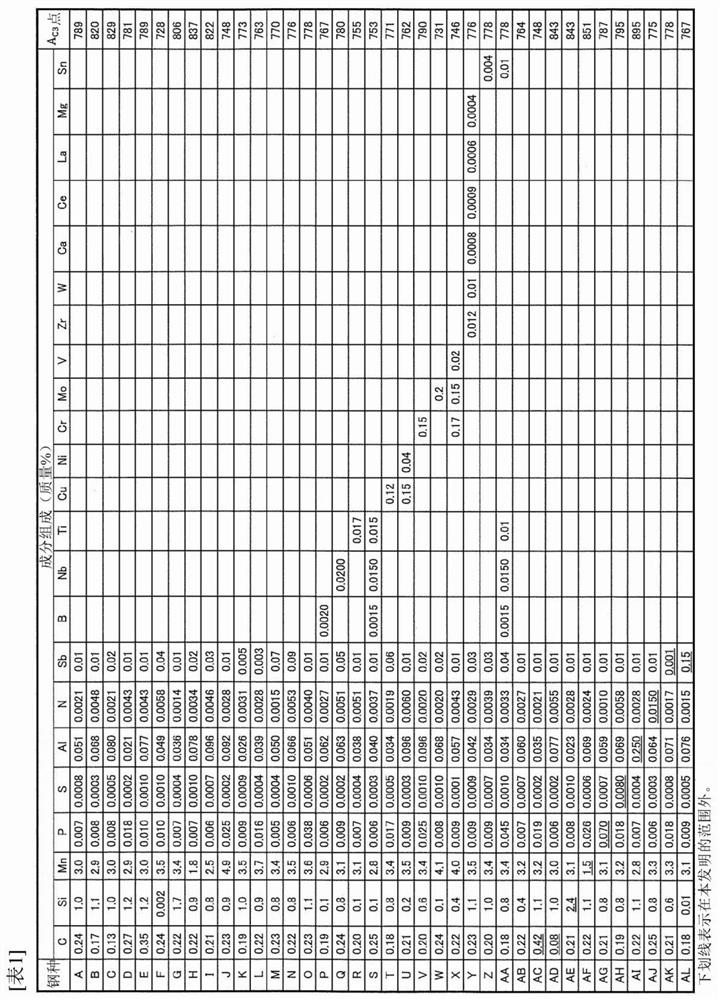

The steel wire material for a spring of the invention contains; C: 0.37-0.54%, Si: 1.7-2.30%, Mn: 0.1-1.30%, Cr: 0.15-1.1%, Cu: 0.15-0.6%, Ti: 0.010-0.1%, Al: 0.003-0.05%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, whole decarburized layer depth is 0.20 mm or less, and fracture reduction of area is 25% or more. It alternately may contain; C: 0.38-0.47%, Si: 1.9-2.5%, Mn: 0.6-1.3%, Ti: 0.05-0.15%, Al: 0.003-0.1%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, Ceq1 in the equation (1) below is 0.580 or more, Ceq2 in the equation (2) below is 0.49 or less, and Ceq3 in the equation (3) below is 0.570 or less.Ceq1=[C]+0.11[Si]−0.07[Mn]−0.05[Ni]+0.02[Cr] (1)Ceq2=[C]+0.30[Cr]−0.15[Ni]−0.70[Cu] (2)Ceq3=[C]−0.04[Si]+0.24[Mn]+0.10[Ni]+0.20[Cr]−0.89[Ti]−1.92[Nb] (3)(In the above equations, [ ] shows the content (mass %) of each element in steel.)

Owner:KOBE STEEL LTD

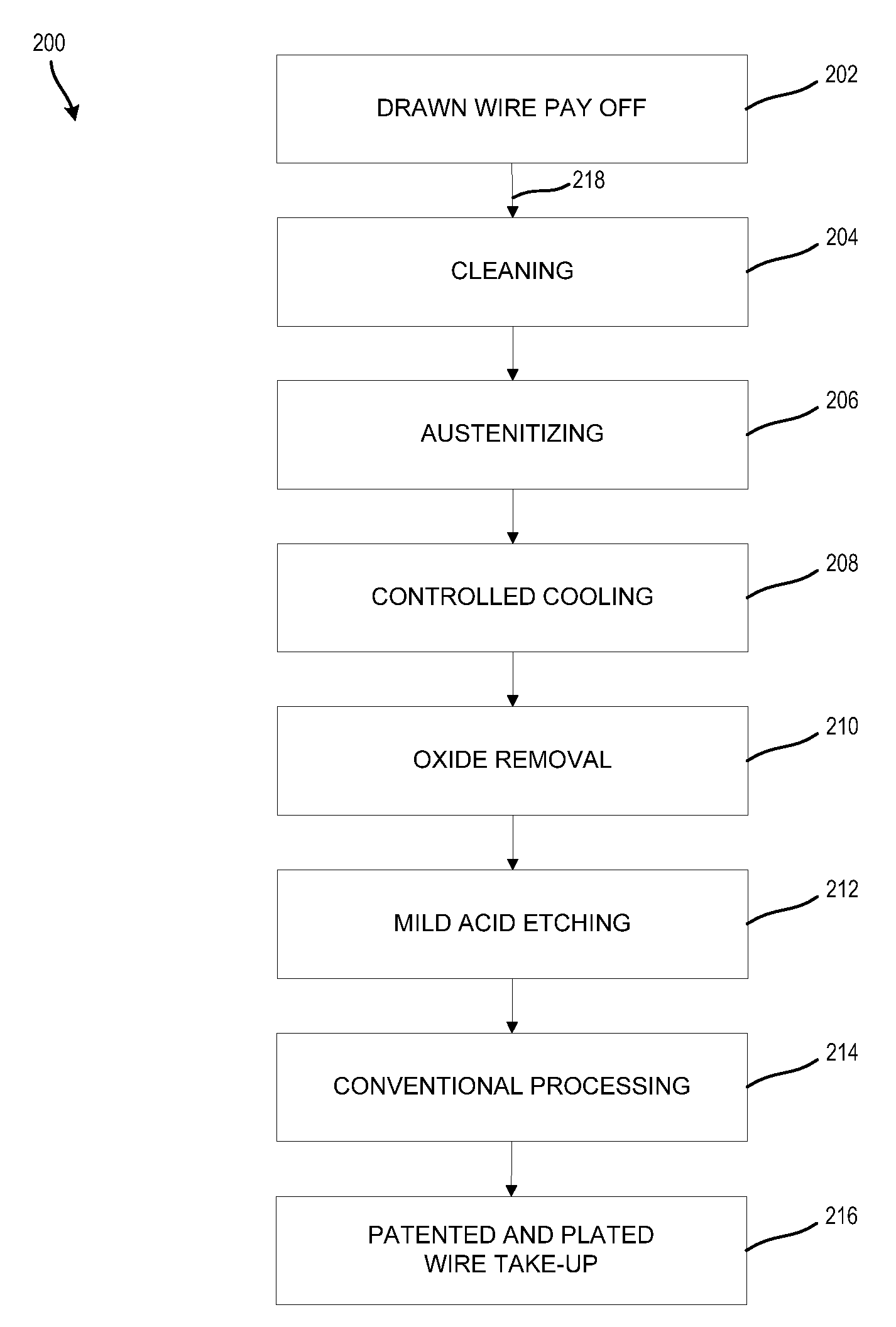

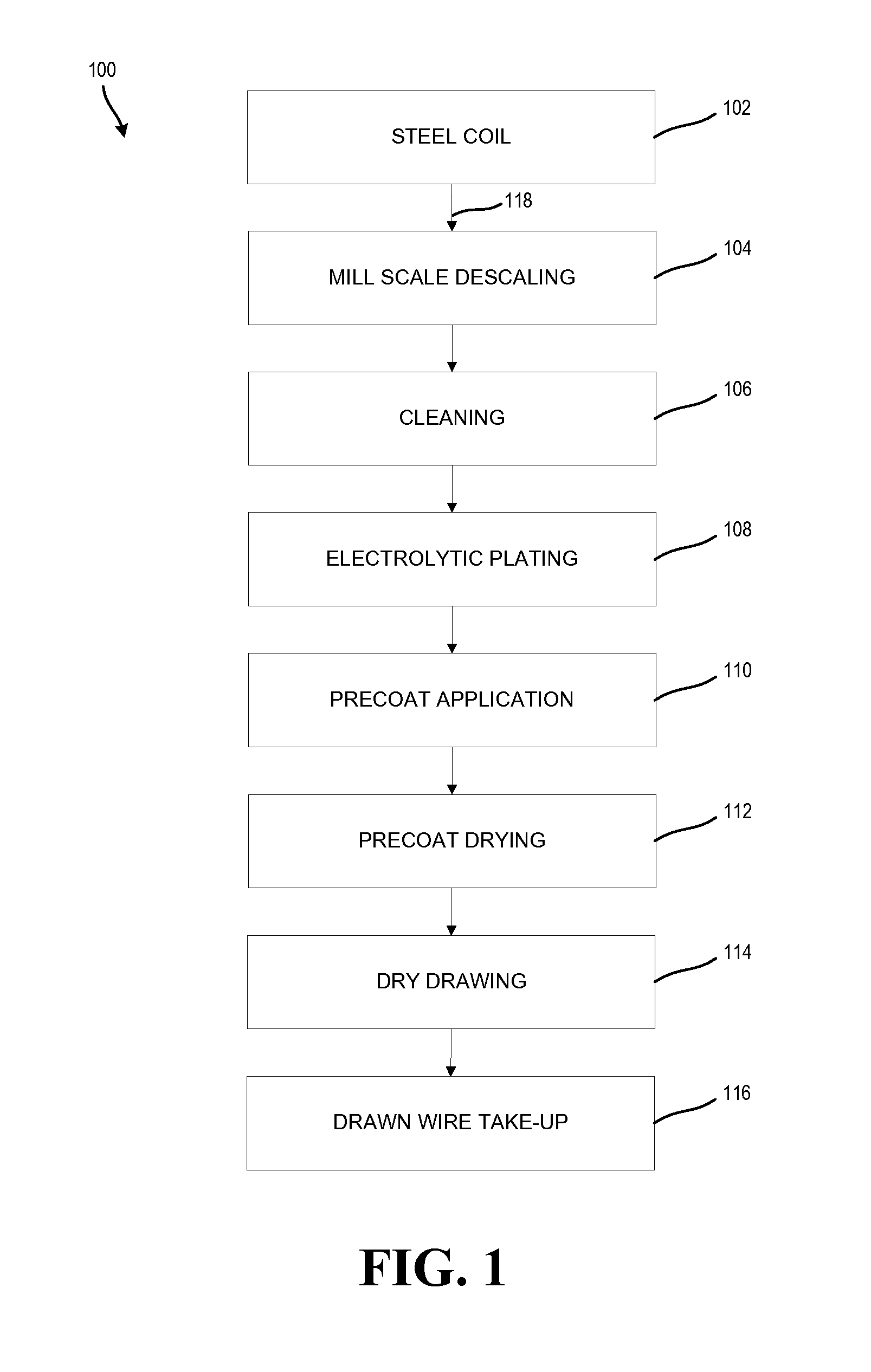

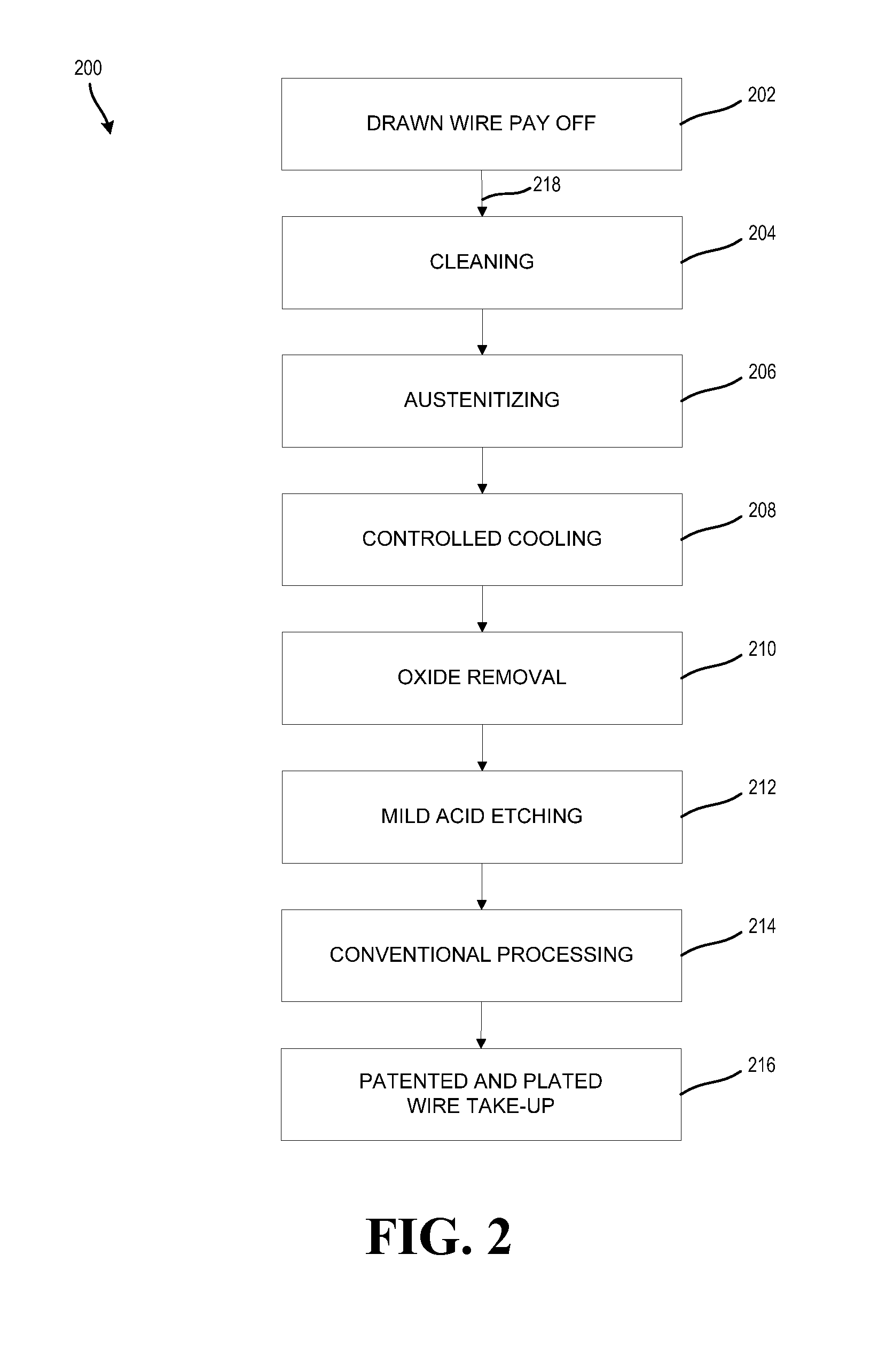

Methods and Systems for Preventing Iron Oxide Formulation and Decarburization During Steel Tempering

InactiveUS20090007997A1Prevent iron oxide formationInhibition of decarburizationFurnace typesHeat treatment furnacesCopper platingElectrolysis

The technology described herein provides a method and system to prevent iron oxide formation and decarburization during strand heat treating of a steel product without the subsequent required use of acid pickling, which has associated health and environmental risks. Additionally, this technology provides placing a coating, such as copper plating, to the surface of a steel wire prior to strand heat treating to avoid both iron oxide formation and decarburization through the surface of the steel wire by preventing interactions between the steel wire and the furnace atmosphere. To remove oxides formed by the plating metal, the oxides are chemically reduced by passing the steel wire through a reducing gas, electrolytically reduced by plating with the wire anodic, mechanically reduced through the use of brushes, or the like, or chemically reduced by acid pickling.

Owner:TYL THOMAS WILSON

Steel wire material for spring and its producing method

ActiveUS20110303327A1High strengthImprove stress conditionFurnace typesHeat treatment process controlFracture reductionNiobium

The steel wire material for a spring of the invention contains; C: 0.37-0.54%, Si: 1.7-2.30%, Mn: 0.1-1.30%, Cr: 0.15-1.1%, Cu: 0.15-0.6%, Ti: 0.010-0.1%, Al: 0.003-0.05%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, whole decarburized layer depth is 0.20 mm or less, and fracture reduction of area is 25% or more. It alternately may contain; C: 0.38-0.47%, Si: 1.9-2.5%, Mn: 0.6-1.3%, Ti: 0.05-0.15%, Al: 0.003-0.1%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, Ceq1 in the equation (1) below is 0.580 or more, Ceq2 in the equation (2) below is 0.49 or less, and Ceq3 in the equation (3) below is 0.570 or less.Ceq1=[C]+0.11[Si]−0.07[Mn]−0.05[Ni]+0.02[Cr] (1)Ceq2=[C]+0.30[Cr]−0.15[Ni]−0.70[Cu] (2)Ceq3=[C]−0.04[Si]+0.24[Mn]+0.10[Ni]+0.20[Cr]−0.89[Ti]−1.92[Nb] (3)(In the above equations, [ ] shows the content (mass %) of each element in steel.)

Owner:KOBE STEEL LTD

Wolfram carbide-cobalt-carbon composite powder for hot spraying and preparation method thereof

InactiveCN103131999AInhibit oxidative decompositionInhibition of decarburizationMolten spray coatingCarbon compositesThermal spraying

The invention relates to a wolfram carbide-cobalt-carbon composite powder for hot spraying and a preparation method thereof. The invention is characterized in that the composite powder contains simple substance carbon, and is composed of the following components in percentage by weight: 5-30% of Co, 60-90% of WC, 1-10% of C, 0-20% of Fe and 0-20% of Cr. The preparation method comprises the following steps: proportionally and directly mixing graphite powder used as a carbon source with other powder components, carrying out ball milling or high-energy ball milling mechanical alloying under the protection of absolute alcohol, kerosene or any other organic solvent, drying, and screening to obtain the composite powder. The invention can also comprise the following steps: by using an organic compound (such as glucose) as a carbon source, proportionally and directly mixing powdered glucose with other powder components, carrying out ball milling under the protection of absolute alcohol, kerosene or any other organic solvent, drying at 60-80 DEG C, carbonizing in a vacuum furnace at 400 DEG C below, carrying out ball milling or high-energy ball milling mechanical alloying, and screening to obtain the composite powder.

Owner:浙江亚通冶金科技有限公司

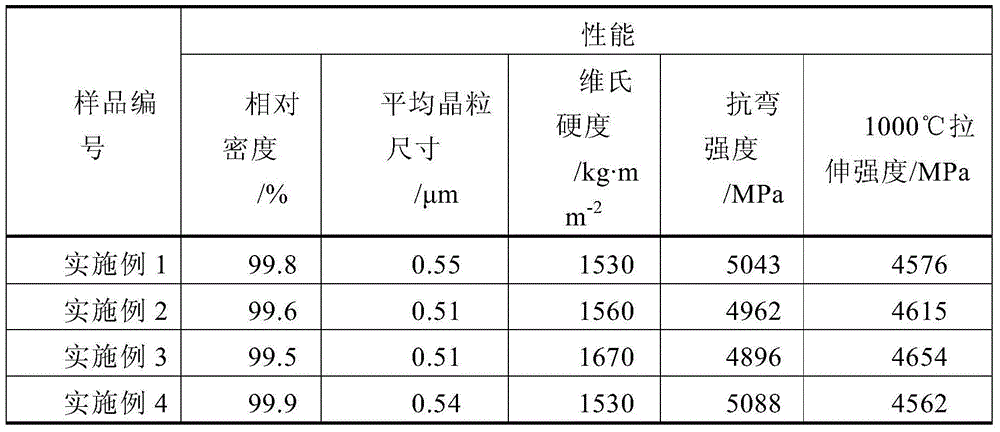

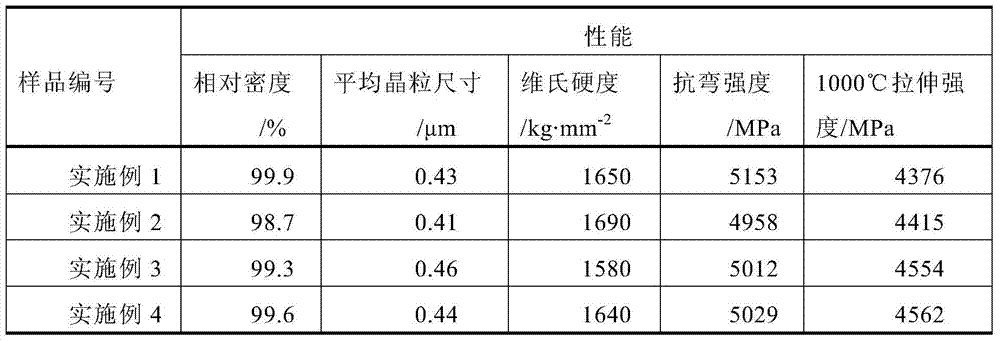

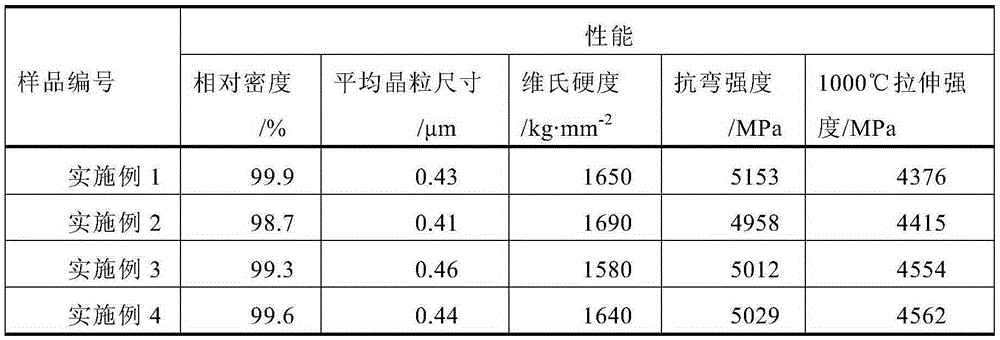

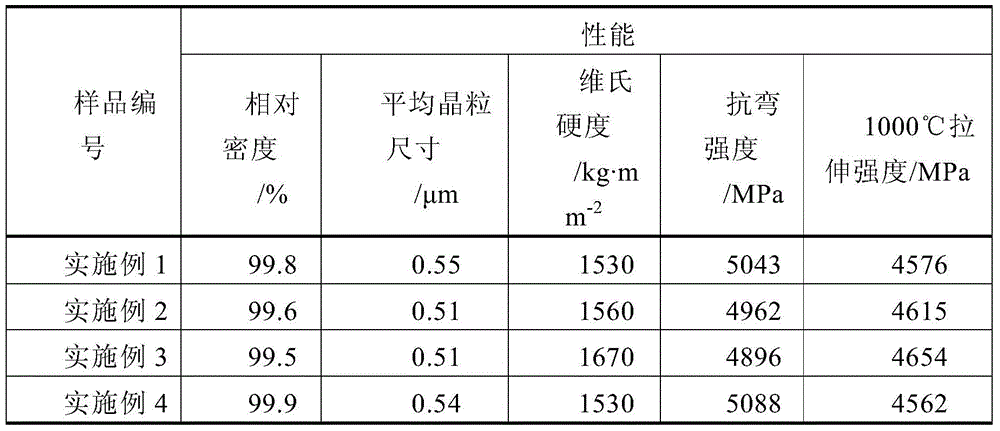

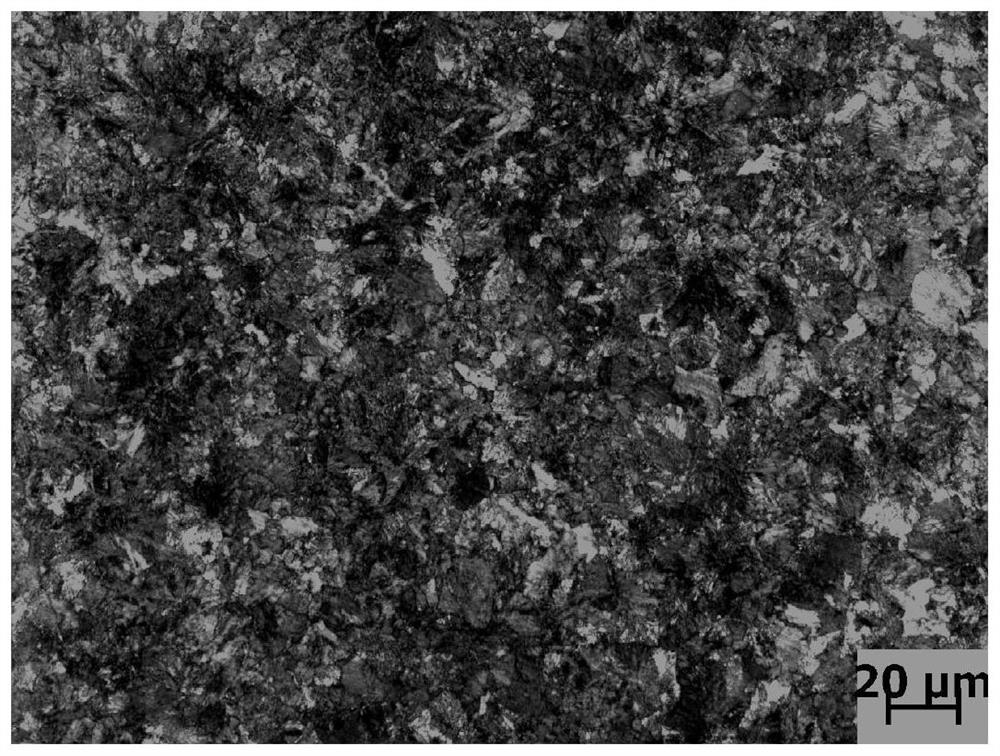

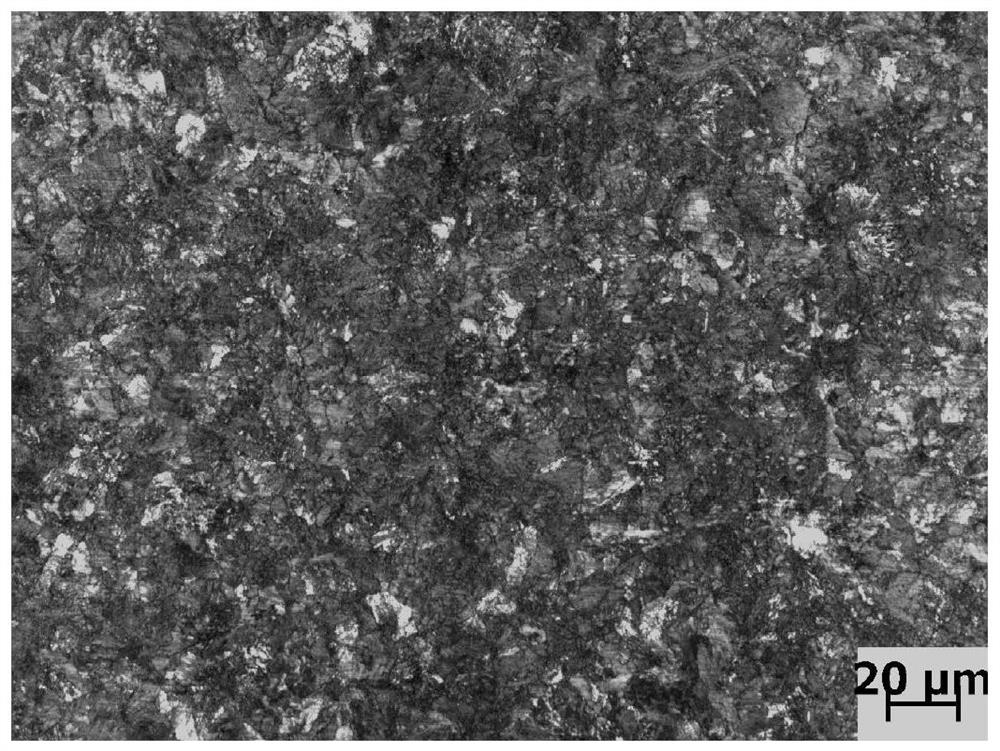

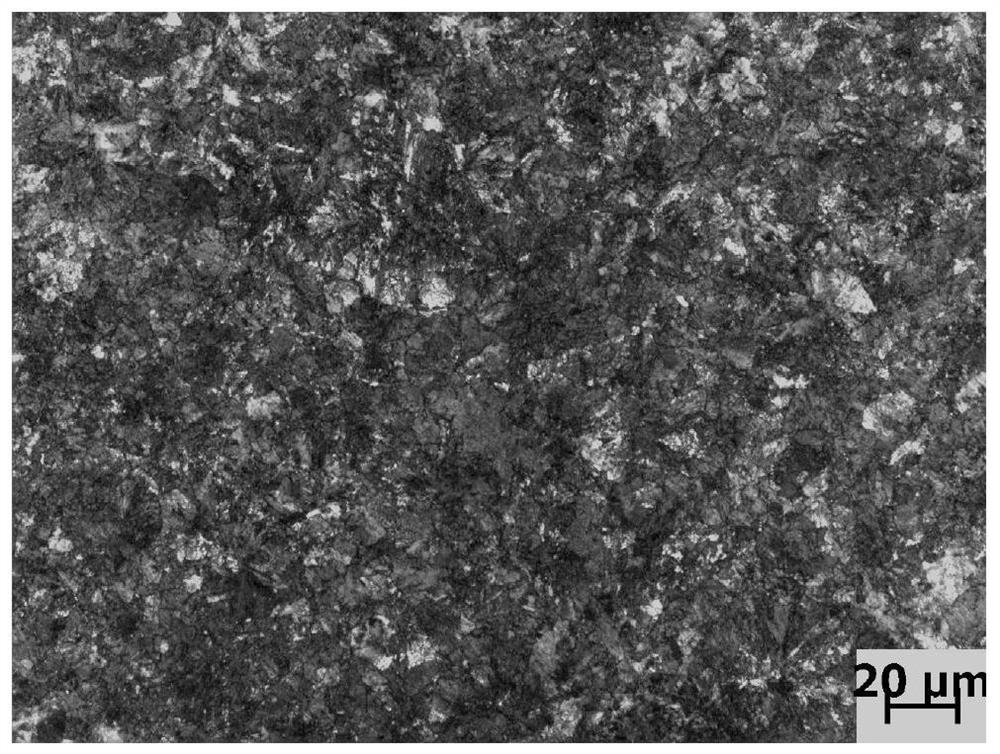

Method for preparing Ni-Fe-based high-temperature binder phase hard alloy

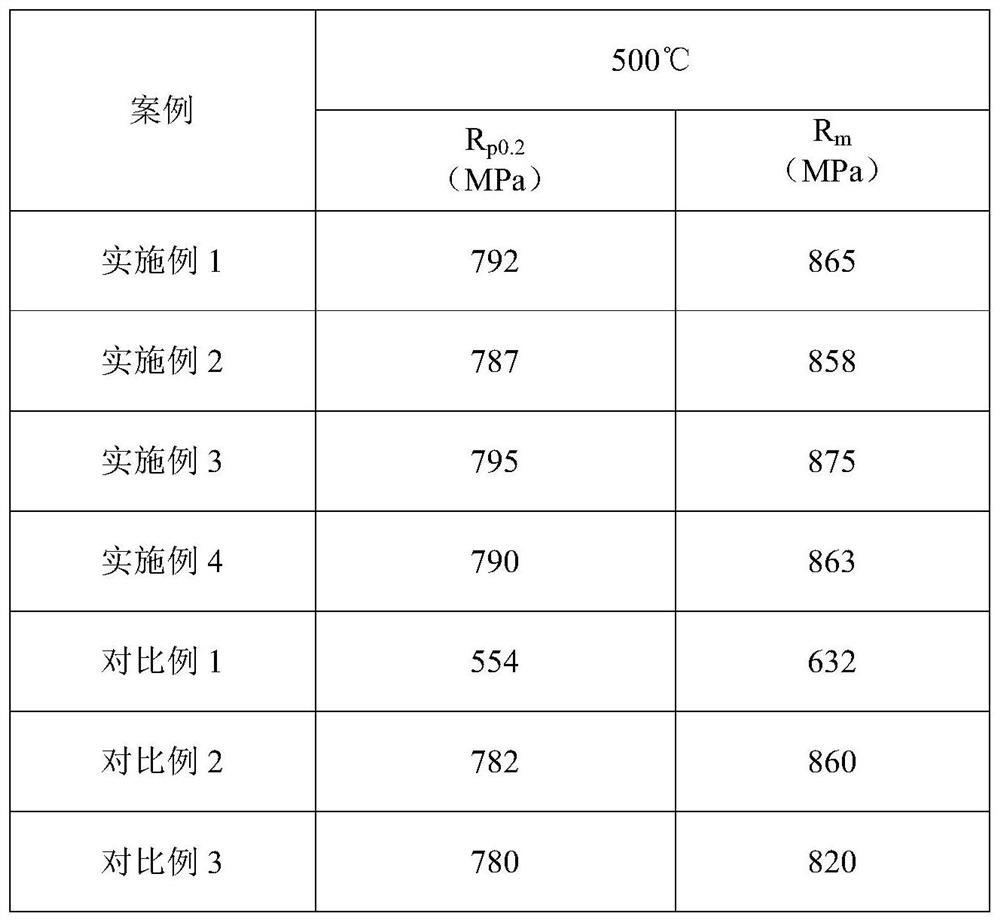

InactiveCN104593626AOvercome the adverse effects of high temperature mechanical propertiesComposition control with high precisionHigh energyFlexural strength

The invention discloses a method for preparing a Ni-Fe-based high-temperature binder phase hard alloy. The method comprises the following steps of firstly mixing nickel powder, iron powder, chromium powder, molybdenum powder and aluminum powder in a predetermined mass ratio and carrying out high-energy ball milling; carrying out ordinary ball milling on powder subjected to high-energy ball milling, tungsten carbide powder, titanium carbide powder and vanadium carbide powder to obtain a mixed powder; loading the prepared mixed powder into a mold and pressing by virtue of cold press to obtain a green body; carrying out sinter molding on the green body material under the protective atmosphere to finally obtain the Ni-Fe-based high-temperature binder phase hard alloy material. According to the method, Ni-Fe-based mechanical alloying powder instead of Co powder is used as a binder, and the prepared hard alloy has Vickers hardness equal to or greater than 1530 / kg.mm<-2>, flexural strength equal to or greater than 4880MPa and tensile strength equal to or greater than 4562MPa at 1000 DEG C.

Owner:SHAANXI UNIV OF TECH

Long-fatigue-life strip steel as well as preparation method and application thereof

The invention relates to long-fatigue-life strip steel as well as a preparation method and application thereof, and belongs to the technical field of steel preparation. The long-fatigue-life strip steel is prepared from the following chemical components in percentage by mass: 0.26 to 0.45 percent of C, 0.10 to 0.25 percent of Si, 1.1 to 1.4 percent of Mn, less than or equal to 0.015 percent of P,less than or equal to 0.003 percent of S, 0.015 to 0.08 percent of Al, 0.01 to 0.05 percent of Ti, 0.0010 to 0.0050 percent of B, 0.10 to 0.30 percent of Cr, less than or equal to 0.006 percent of N,and at least one of the following chemical components in percentage by mass: 0.05 to 0.2 percent of Sb, 0.05 to 0.2 percent of Sn, and the balance of Fe and inevitable impurities. A hollow stabilizerbar is prone to surface decarburization in the plurality of heat treatment in the raw material production and follow-up forming process, so that the surface hardness is reduced, and the fatigue life is shortened. The tin / antimony element is prone to enrich on the surface layer of steel to inhibit the diffusion of C from the strip steel, so that decarburization of the surface layer is inhibited. Atleast one of Sb and Sn is added into the chemical components of the material, so that the fatigue life of the final part hollow stabilizer bar is prolonged by reducing surface decarburization of thematerial.

Owner:SHOUGANG CORPORATION +1

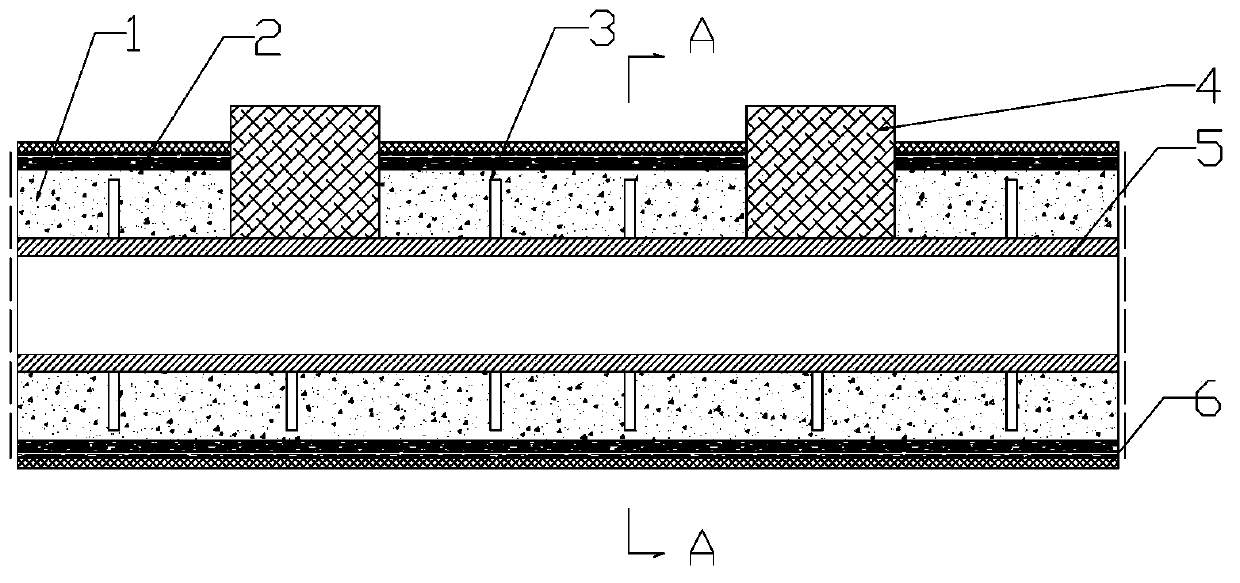

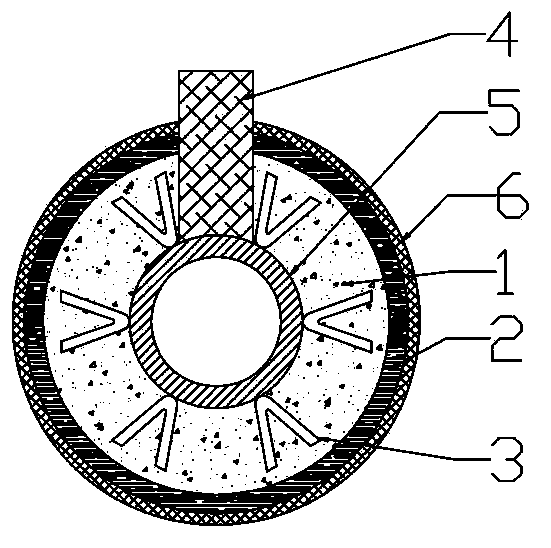

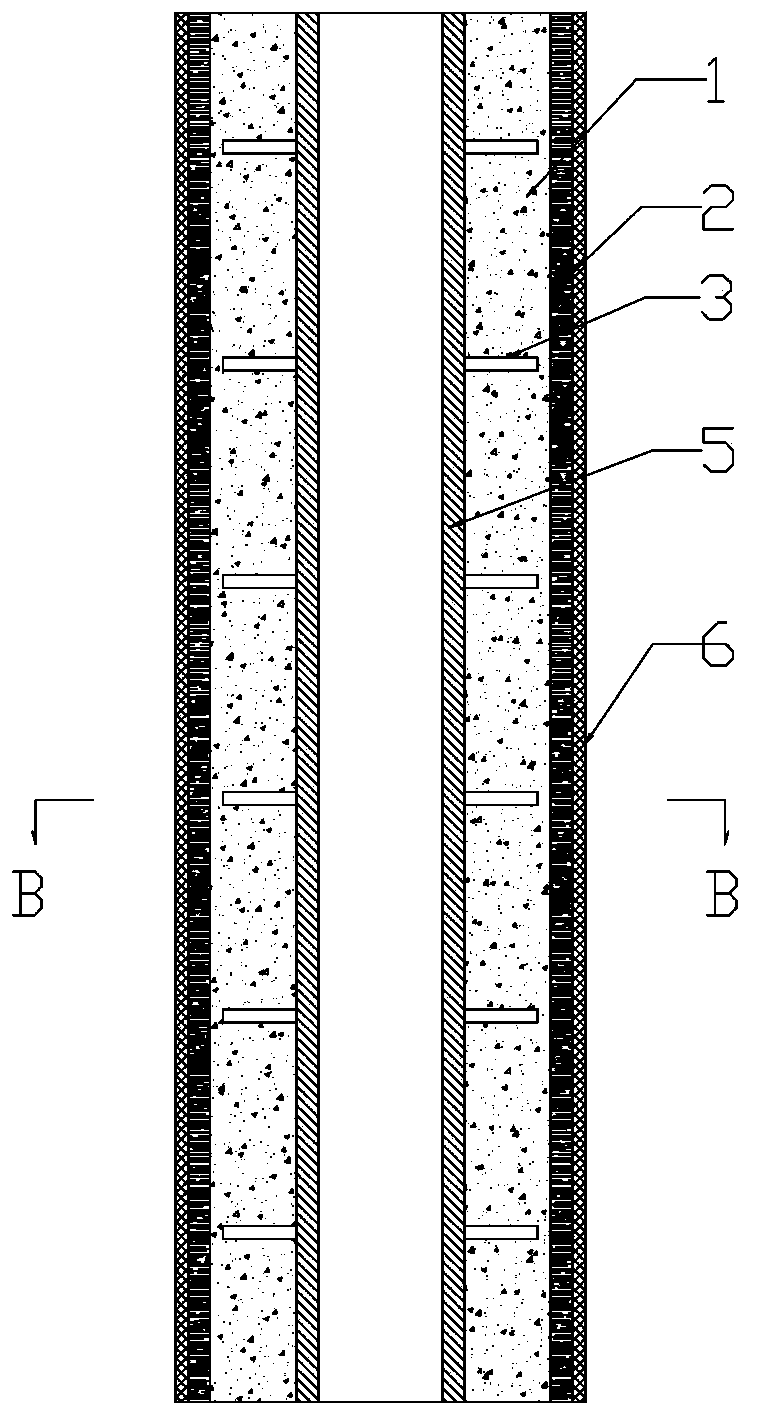

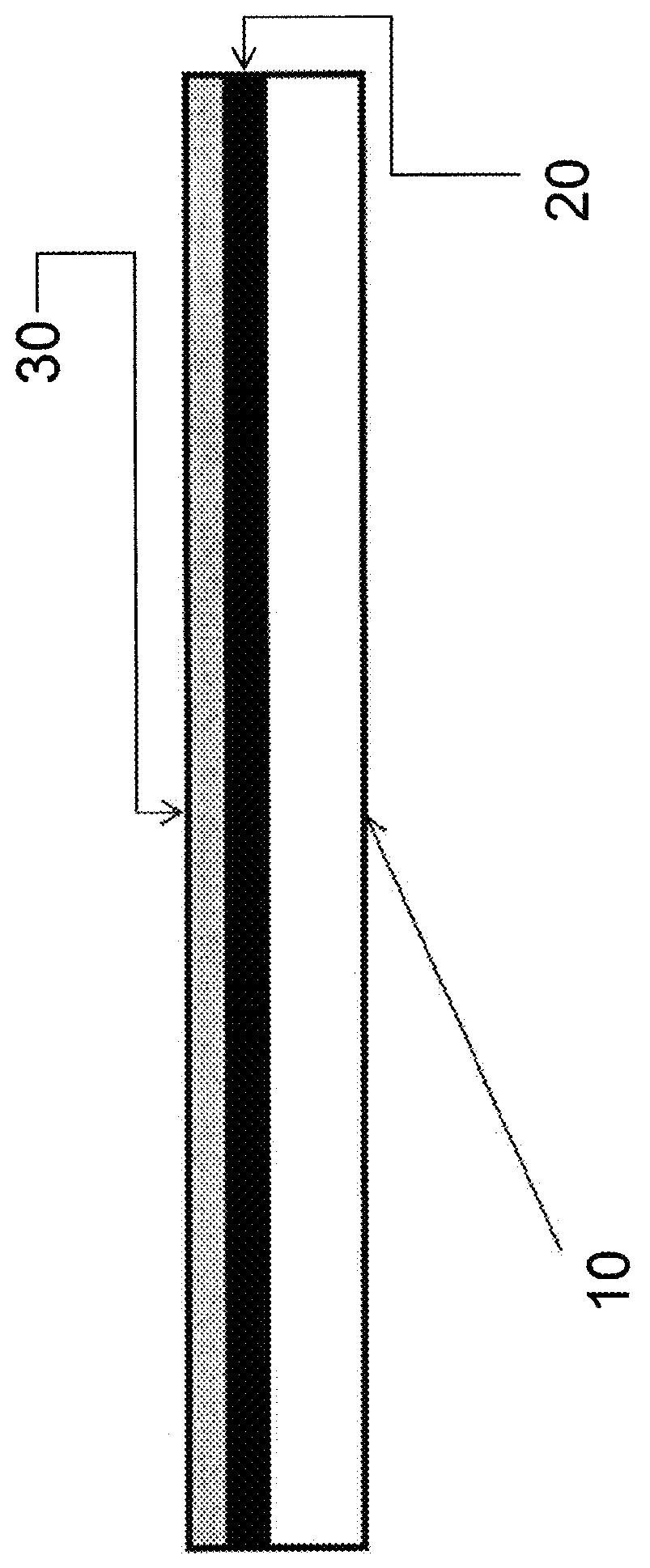

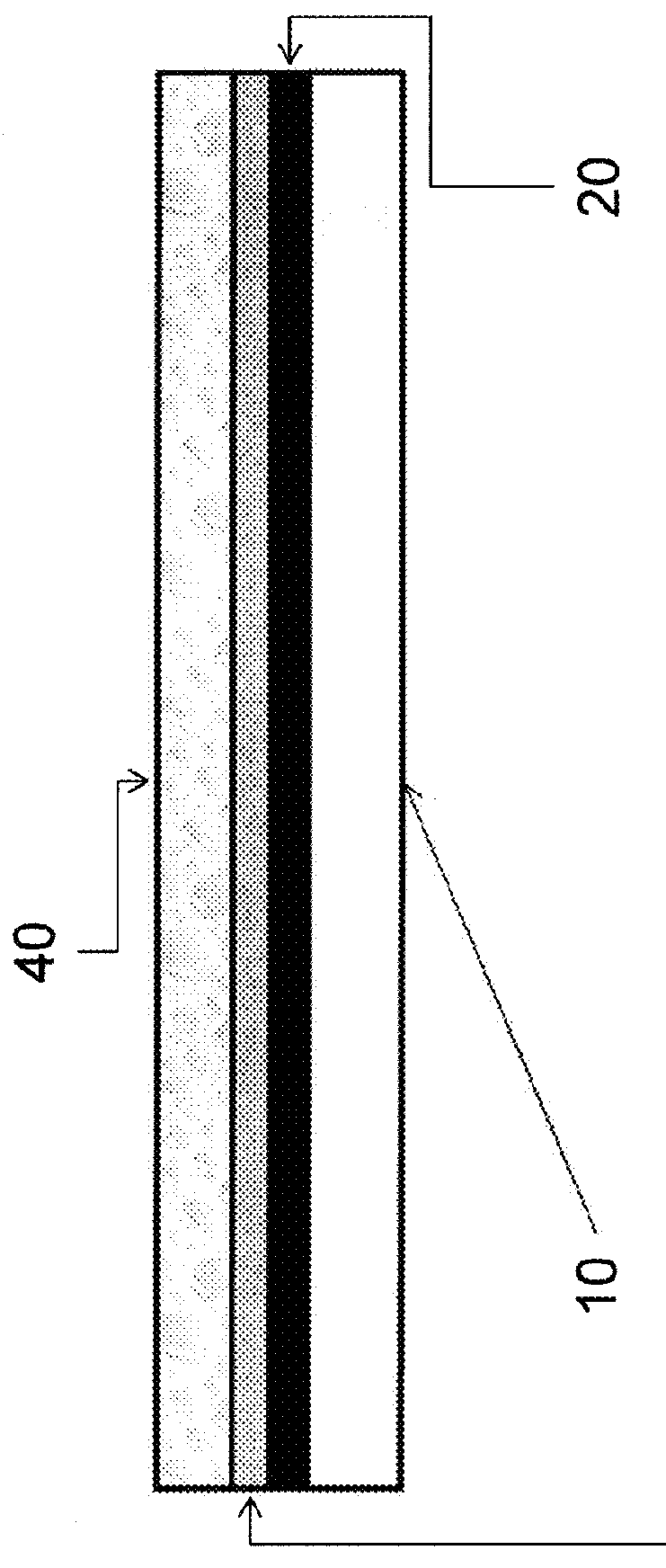

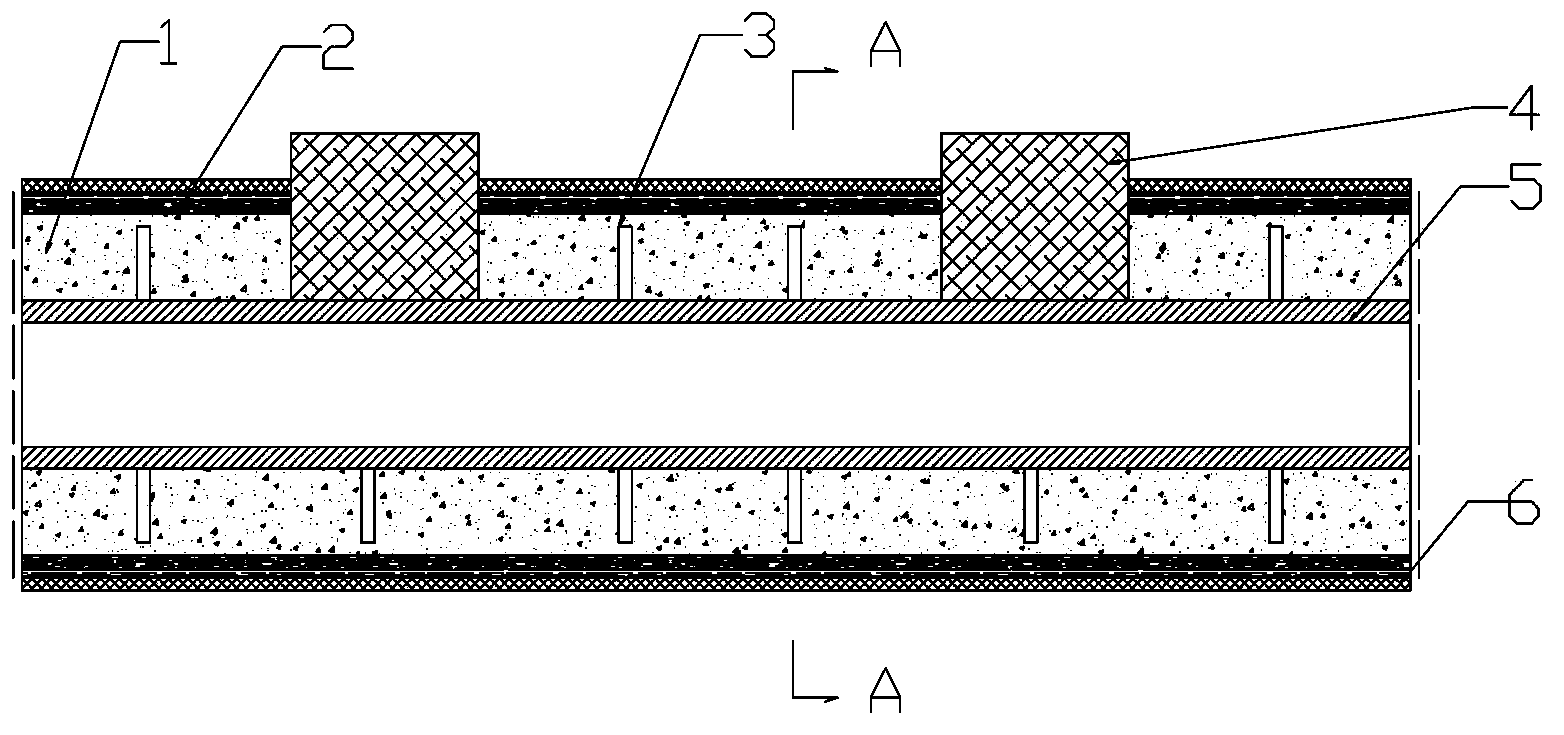

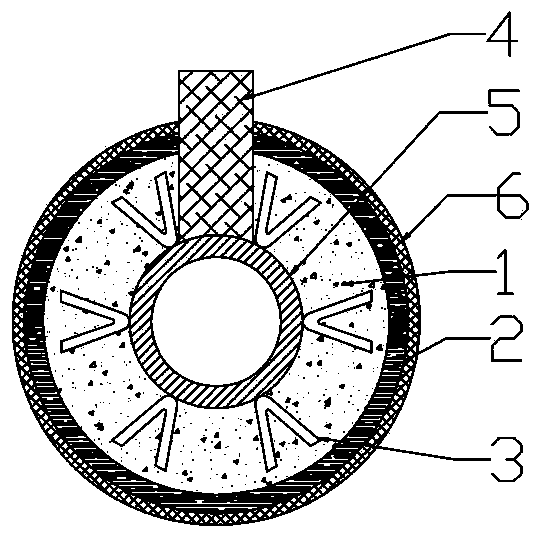

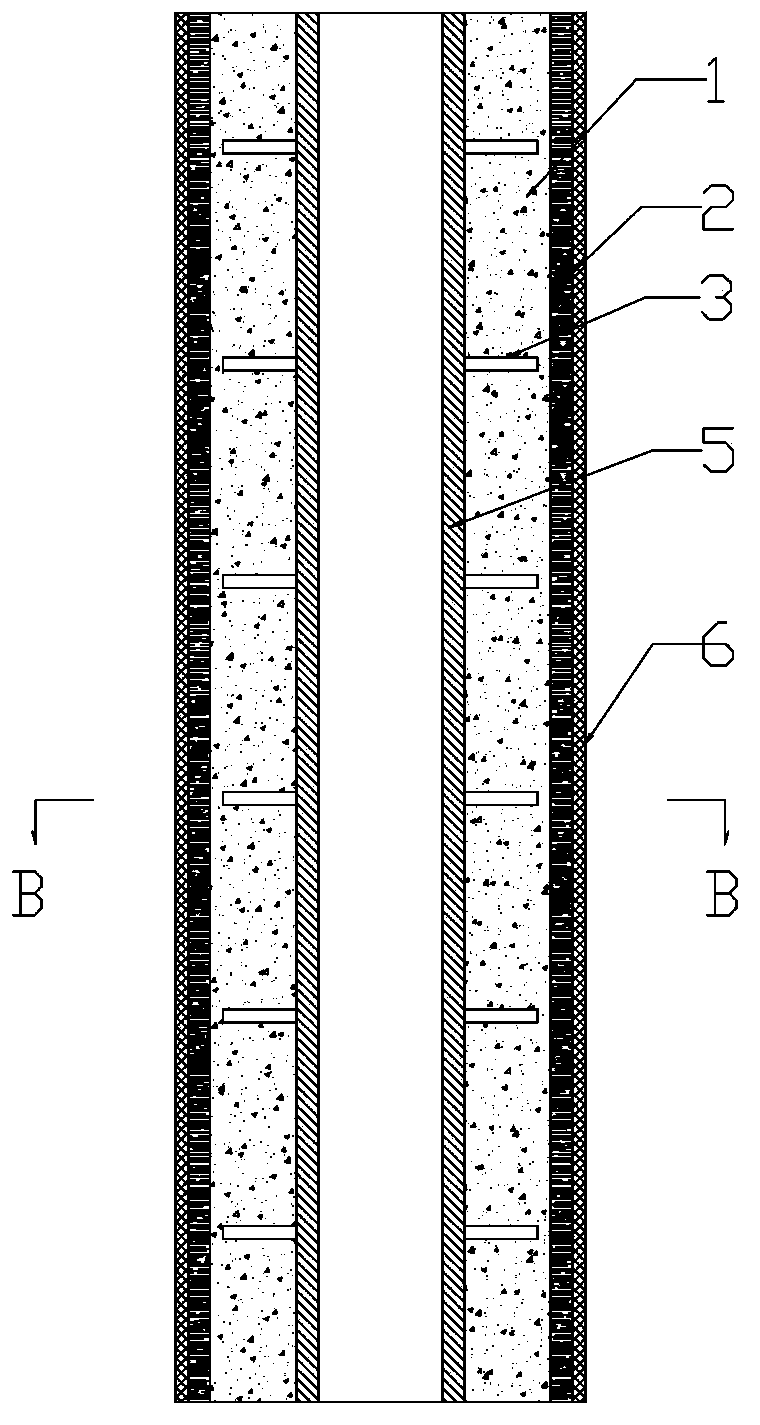

Furnace beam and vertical column fire-resistant thermal insulation lining structure of walking beam furnace for heating high-temperature oriented silicon steel and manufacturing method of structure

The invention discloses a furnace beam and vertical column fire-resistant thermal insulation lining structure of a walking beam furnace for heating high-temperature oriented silicon steel. The furnace beam and vertical column fire-resistant thermal insulation lining structure comprises a metal pipe forming a foundation of a furnace beam or a vertical column, wherein heat-resistant cushion blocks are arranged on the metal pipe forming the foundation of the furnace beam at intervals along the axis direction, metal anchoring parts are uniformly distributed on the outer wall of the metal pipe along the axial direction and the peripheral direction, a fire-resistant insulating layer is formed to cling to the outer wall of the metal pipe in a pouring manner and is combined with the metal anchoring parts, and the fire-resistant insulating layer is sequentially covered by a slag-bonding prevention layer and an anti-oxidation coating. As the heat preservation and slag-bonding prevention double-layer structure and the design of appropriate thickness are adopted by the furnace beam and vertical column fire-resistant thermal insulation lining structure of the walking beam furnace, the integrality of a thermal insulation lining is improved, and the comprehensive usability of the thermal insulation lining is improved.

Owner:武汉钢铁有限公司

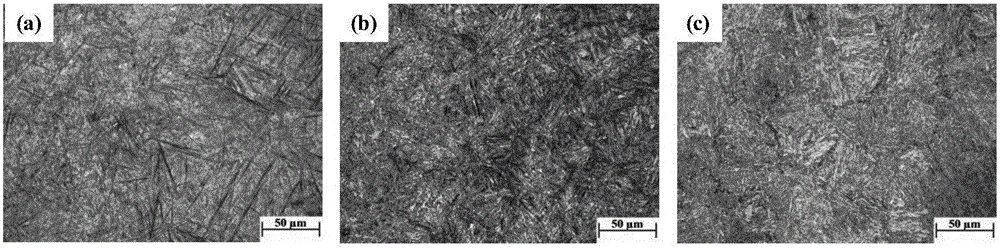

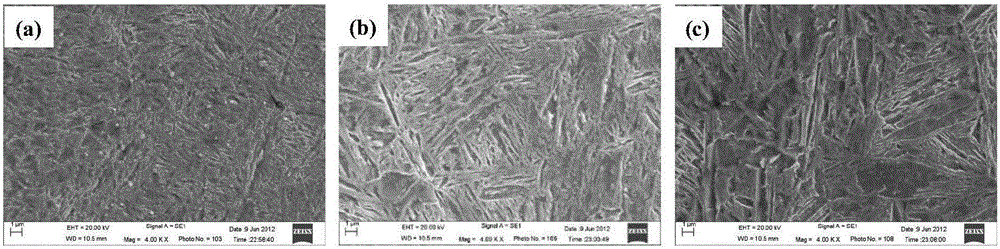

Heat treatment process of brazing tool steel XGQ25 with gradient hardness distribution

InactiveCN105821371AExtended service lifeGood match of strength and toughnessSolid state diffusion coatingHigh carbonHigh surface

The invention relates to a heat treatment process of brazing tool steel XGQ25 with gradient hardness distribution; and the process can realize reasonable gradient hardness distribution of a carburized brazing tool from the surface to the basal body. The process comprises the following steps: the carburized brazing tool is quenched and insulated by 60 minutes at 800+-10 DEG C, and is cooled by three stages after the insulation is finished; firstly, the oil cooling is performed to reach 400+-10 DEG C; then, the furnace cooling is performed to reach 200 DEG C, and the cooling speed is 0.05-0.1 DEG C / s; and then, the air cooling is performed below 200 DEG C to reach the room temperature. The tempering insulation is performed by 120 minutes at 200 DEG C; and the air cooling is performed to reach the room temperature after the insulation is finished. Through actuation of the process, the carburized brazing tool forms a high-carbon martensite structure (HV640-660) with high surface hardness, a lower bainite structure (no-gap impact power of 115-120 J) with high center toughness and a lower bainite and low-carbon martensite complex-phase structure with a wider transition layer (width of 0.5-1.0 mm), so that excellent toughness matchability is obtained, and the service life of the brazing tool is effectively prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Friction stir welding tool made of cemented tungsten carbide with nickel and with a al2o3 surface coating

ActiveUS20140312099A1Inhibition of decarburizationPrevent oxidationWelding/cutting auxillary devicesAuxillary welding devicesCemented carbideMaterials science

A friction stir welding tool for welding of metallic plates and especially steel plates. The friction stir welding tool is made of cemented carbide comprising WC grains in a binder phase and wherein the welding tool is at least partly coated with a surface coating comprising Al2O3.

Owner:HYPERION MATERIALS & TECH SWEDEN AB

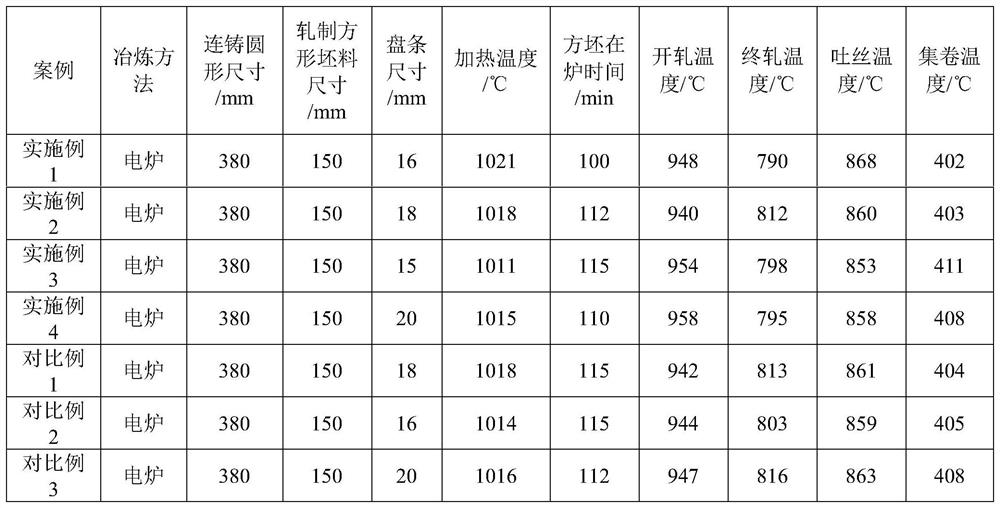

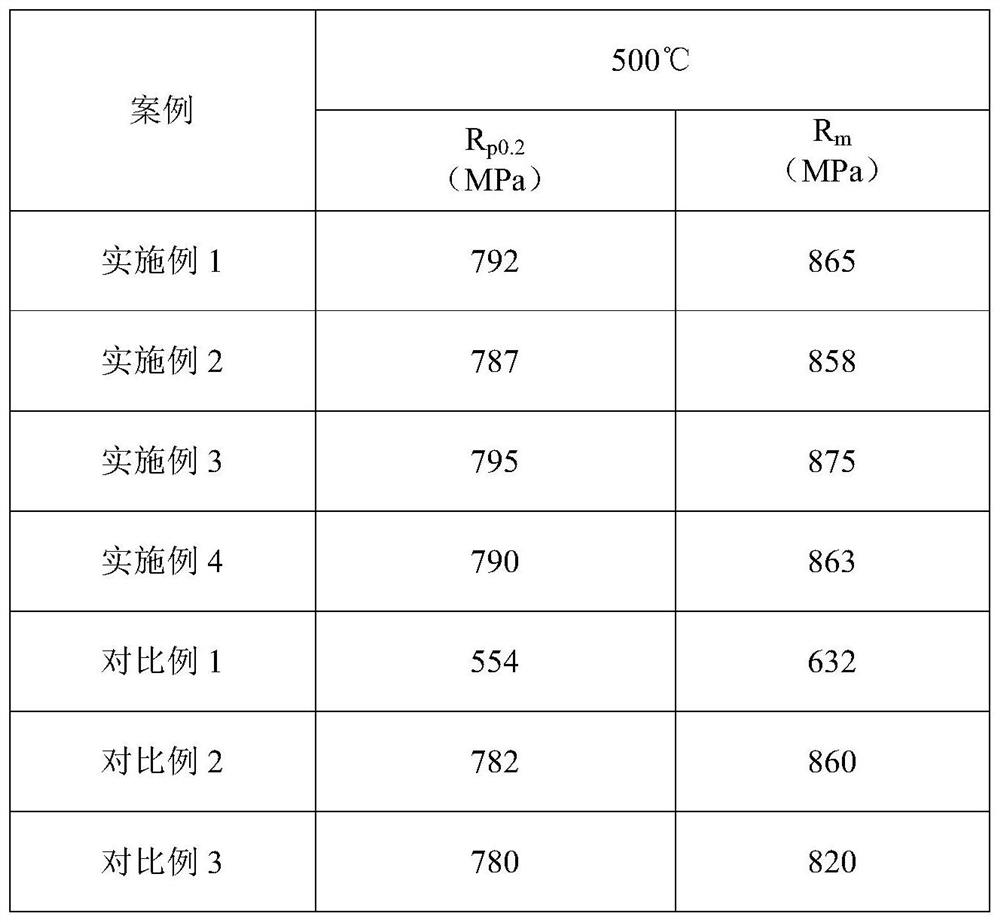

Spring steel with good heat resistance and impact resistance and production method thereof

ActiveCN111690875AImprove heat resistanceGuaranteed room temperature performanceWire rodElectric arc furnace

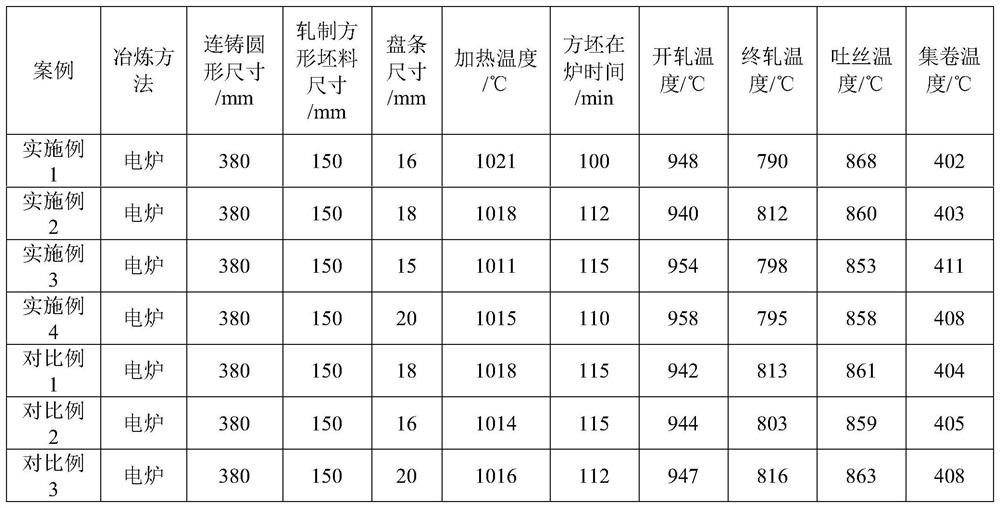

The invention discloses spring steel with good heat resistance and impact resistance and a production method thereof, and belongs to the technical field of spring steel production. The spring steel comprises the following chemical components of, in percentage by weight, 0.50 %-0.60 % of C, 1.60 %-2.20 % of Si, 0.80 %-1.00 % of Mn, 0.80 %-1.30 % of Cr, 0.20 %-0.50 % of Mo, 0.70 %-1.30 % of W, 0.20%-0.40 % of V, 0.02 %-0.04 % of Nb, 0.015 %-0.030 % of Ti, 0.15 %-0.30 % of Ni, 0.15 %-0.30 % of Cu, trace-0.015 % of P, trace-0.010 % of S, less than or equal to 0.0012 % of O, less than or equal to0.006 % of N and the balance Fe and other inevitable impurities. The production method of the spring steel comprises the steps of electric arc furnace smelting, LF furnace refining, RH or VD vacuum degassing, round billet continuous casting, square billet rolling, flaw detection, scaling, high-speed wire rod controlled rolling, stelmor cooling wire controlled cooling treatment and heat treatment.According to the technical scheme, the obtained spring steel has good heat resistance, impact resistance and hydrogen embrittlement fracture resistance, and therefore the use requirements of the spring steel at high temperature and high pressure can be effectively met.

Owner:MAANSHAN IRON & STEEL CO LTD

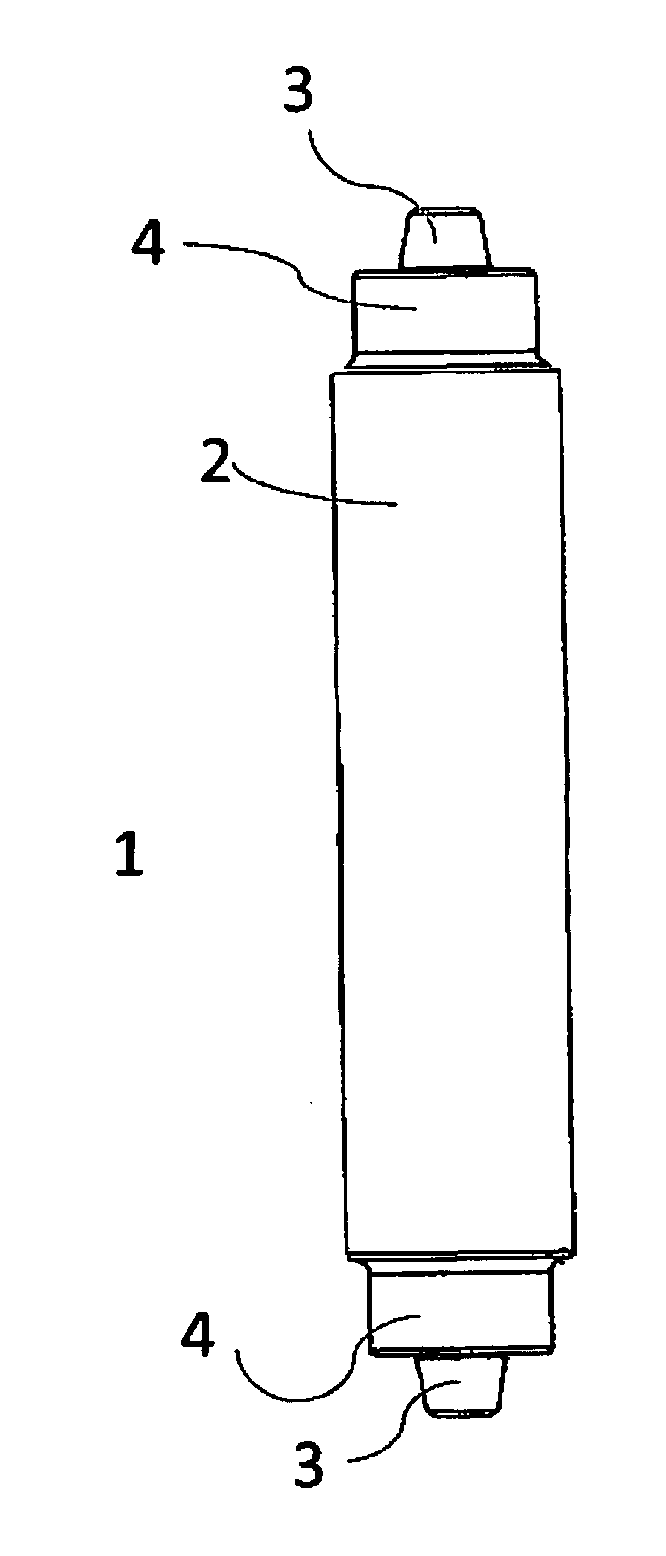

Molten metal casting die

InactiveUS8418744B2Extended service lifeEnhance layeringCasting safety devicesFoundry mouldsLiquid copperMolten metal

A molten metal casting die having a modified surface, a method for making such dies, and a method for making articles of manufacture from such dies is disclosed. The methods are designed to protect die steel surfaces having a protective coating from corrosion by molten metals substantially containing liquid copper.

Owner:NONFERROUS MATERIALS TECH DEV CENT

Aluminum-containing high-strength steel and preparation method and application of aluminum-containing high-strength steel

The invention provides aluminum-containing high-strength steel and a preparation method and application of the aluminum-containing high-strength steel. The aluminum-containing high-strength steel is prepared from the following chemical components including, by mass: 0.1% to 0.2% of C, 0.3% to 0.6% of Si, 2% to 3% of Mn, less than or equal to 0.0015% of P, less than or equal to 0.0015% of S, 0.5% to 1% of Al, 0.1% to 0.3% of Mo, 0.01% to 0.05% of Pb and the balance of Fe and inevitable impurities. The aluminum-containing high-strength steel provided is good in surface and free of chromatic aberration defects after being galvanized.

Owner:SHOUGANG CORPORATION +1

Steel for single-layer concrete conveying pipe of trailer pump vehicle and production method thereof

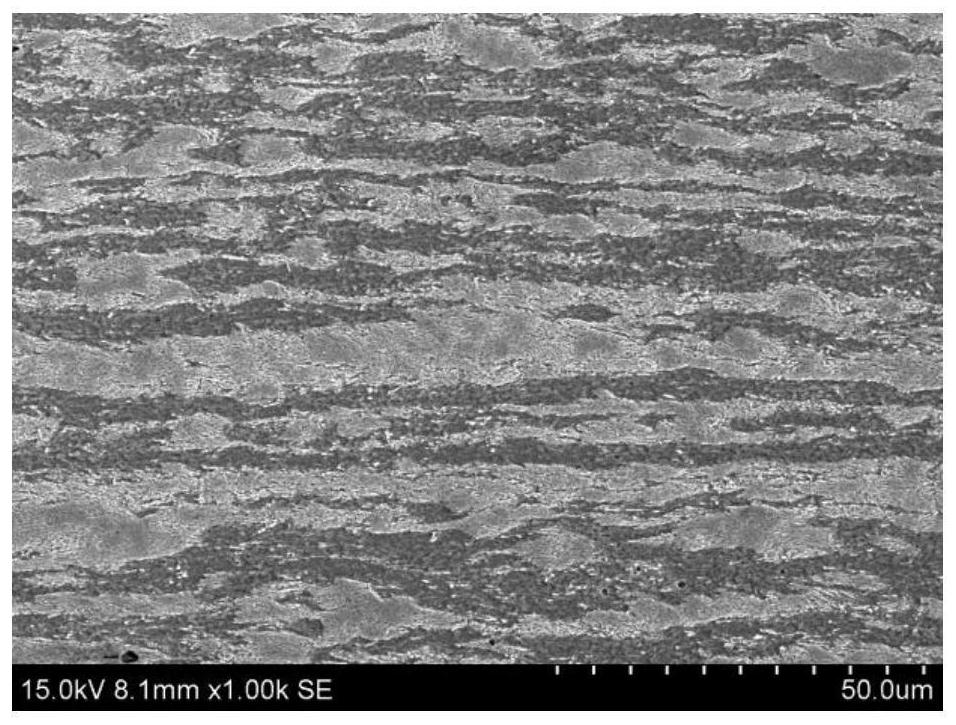

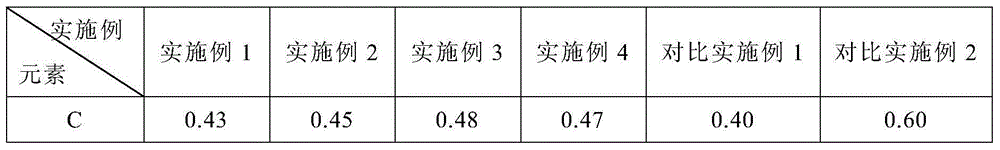

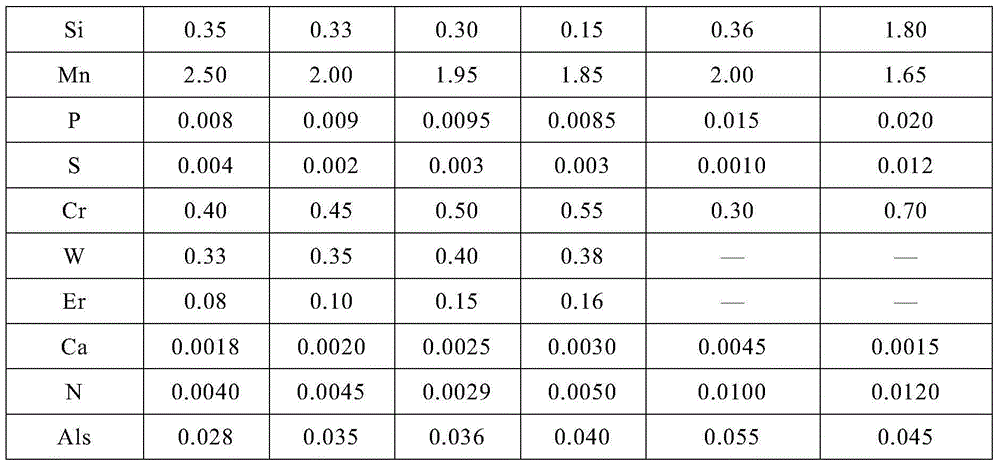

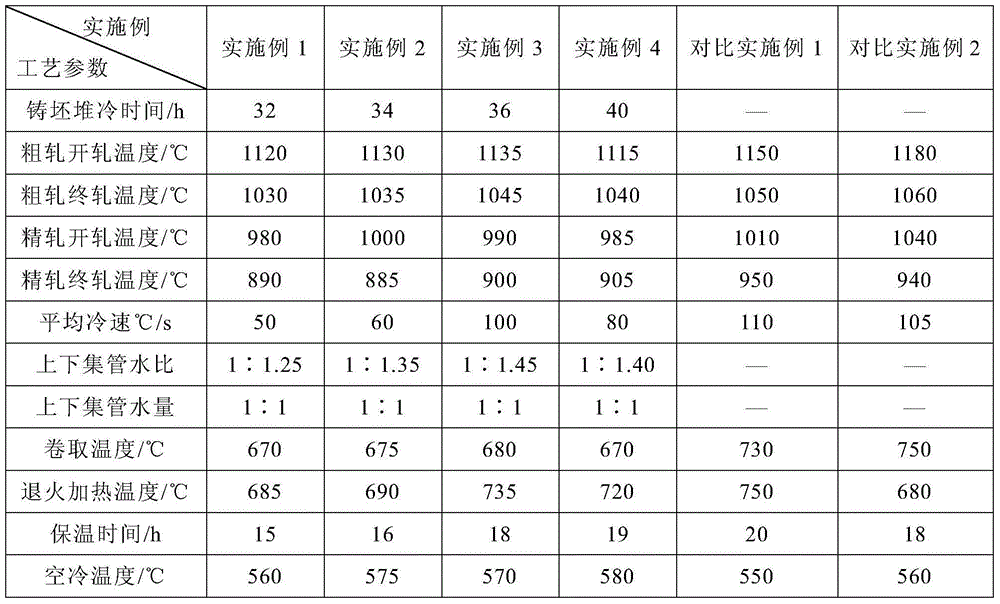

The invention discloses steel for a single-layer concrete conveying pipe of a trailer pump vehicle and a production method thereof. The steel for the single-layer concrete conveying pipe of the trailer pump vehicle includes 0.38-0.48% of carbon, 0.05-0.35% of silicon, 1.60-2.50% of manganese, 0.0015-0.0030% of calcium, 0.35-0.65% of chromium, 0.30-0.50% of tungsten, 0.05-0.20% of erbium, 0.015-0.045% of aluminum, less than or equal to 0.010% of phosphorus, less than or equal to 0.003% of sulfur, less than or equal to 0.006% of nitrogen, and rest of iron and unavoidable impurity. The steel is high in wear-resisting property, the proper final rolling and coiling temperature is controlled in the production process, the standing time of a steel coil at a two-phase region is reduced, the steel is quickly cooled to a pseudo-eutectoid pearlite precipitation zone, the proeutectoid ferrite production is reduced, the proeutectoid ferrite is not generated in a slow cooling process after coiling, and meanwhile, the bainite formation due to a too low coiling temperature is avoided, and more pearlite is formed.

Owner:WUHAN IRON & STEEL (GROUP) CORP

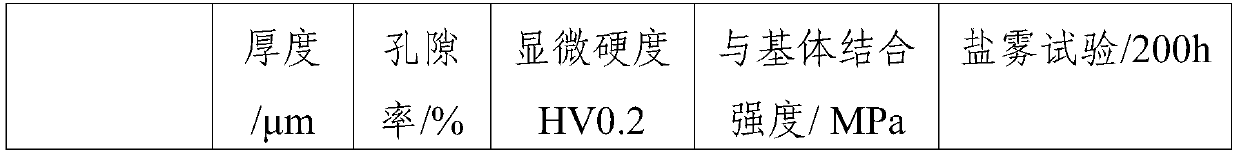

Preparation method of high-wear-resistance and high-corrosion-resistance protective layer of hot work die steel

InactiveCN111004991AGood protectionEnhanced goodMolten spray coatingSolid state diffusion coatingTemperingHot work

The invention provides a preparation method of a high-wear-resistance and high-corrosion-resistance protective layer of hot work die steel, and relates to the technical field of die steel. The preparation method of the protective layer comprises the following steps: (1) carrying out surface purification treatment and surface roughening treatment; (2) carrying out preheating treatment, then spraying a coating by adopting a hypersonic flame spraying method, carrying out compressed air cooling, and the spraying powder being prepared from the following components in percentage by weight: 55 to 64percent of WC, 12 to 18 percent of TaC, 3 to 4.5 percent of VC, 0.8 to 1.5 percent of nano rare earth oxide and the balance of NiCr; and (3) carrying out carburizing treatment, quenching and tempering. According to the method, the hot work die steel is subjected to surface roughening treatment, hypersonic flame spraying, carburizing treatment, quenching and tempering, so that a high-wear-resistance and high-corrosion-resistance coating can be formed on the surface of the hot work die steel, the bonding strength between the coating and a base body is high, and excellent surface protection and strengthening can be formed on the hot work die steel.

Owner:安徽旭通网络科技有限公司

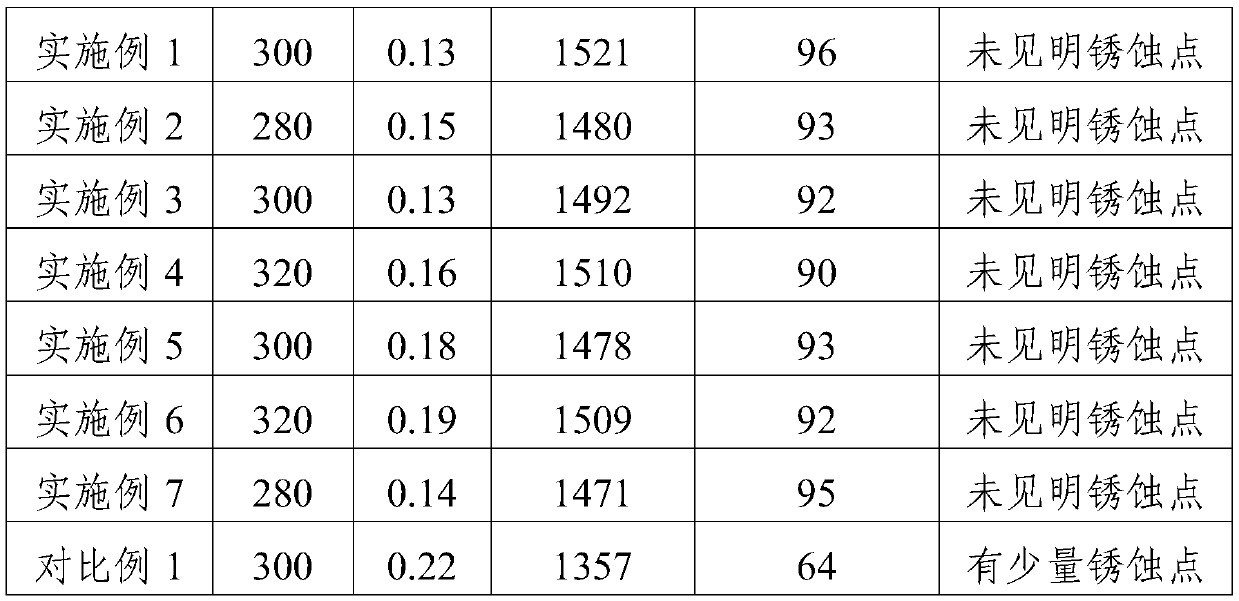

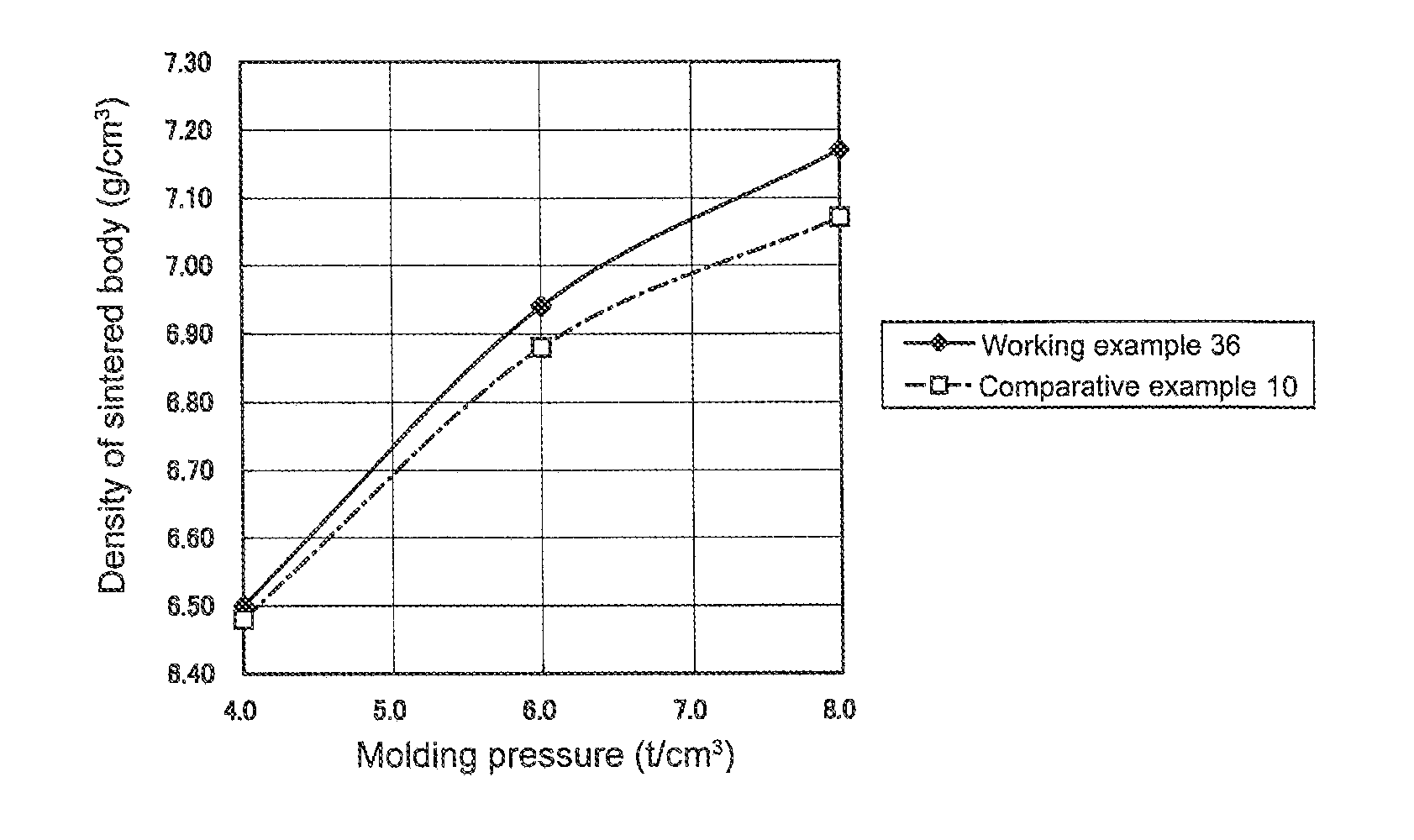

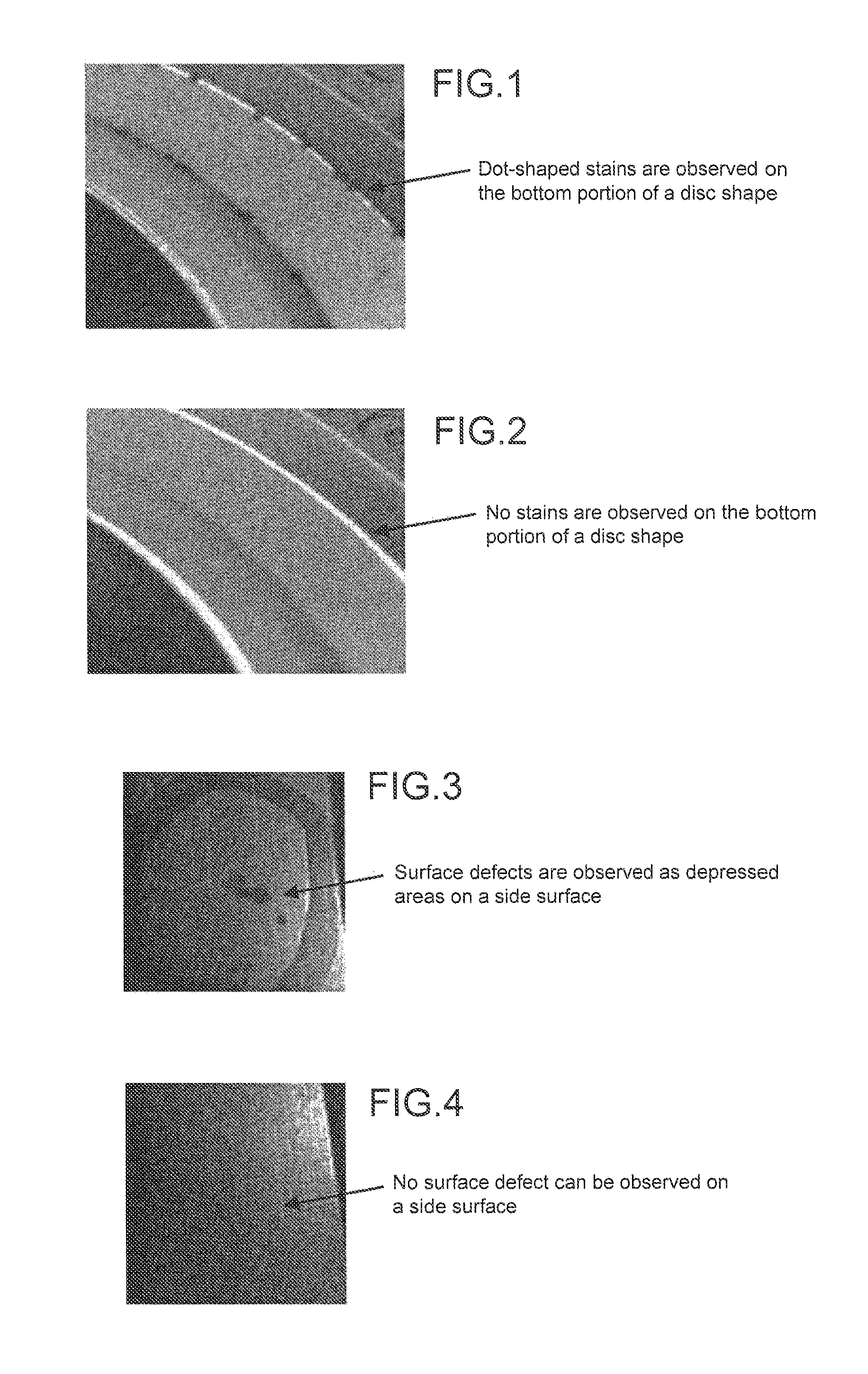

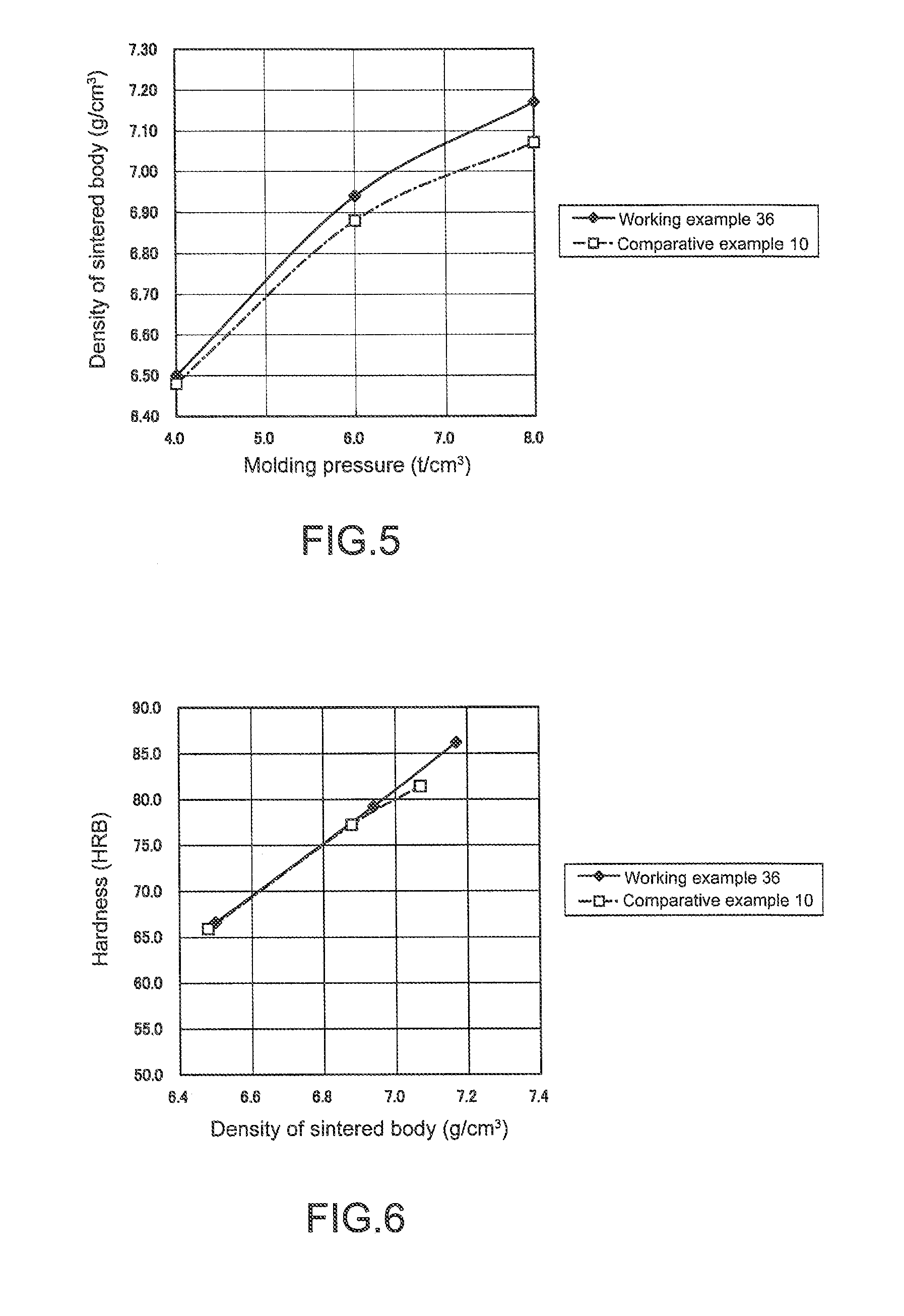

Raw material powder for powder metallurgy

ActiveUS20150283609A1High strengthHigh densityTransportation and packagingMetal-working apparatusStearic acidUltimate tensile strength

Provided is a raw material powder for powder metallurgy, capable of preventing stains, surface defects and decarburization of a sintered body, improving strength and density thereof. The raw material powder for powder metallurgy is for use in the production of a sintered body that is sintered at a temperature of not lower than 500° C., composed of a mixture of a metal powder and a lubricant, in which the lubricant is melamine cyanurate or terephthalic acid. Alternatively, the raw material powder for powder metallurgy is for use in the production of a sintered body that is sintered at a temperature of not lower than 500° C., composed of a mixture of a metal powder, a first lubricant and a second lubricant, in which the first lubricant is melamine cyanurate or terephthalic acid, while the second lubricant is preferably erucic acid amide or stearic acid amide.

Owner:DIAMET CORP

Steel wire material for spring and its producing method

ActiveUS8382918B2High strengthImprove stress conditionFurnace typesHeat treatment process controlFracture reductionMetallurgy

The steel wire material for a spring of the invention contains; C: 0.37-0.54%, Si: 1.7-2.30%, Mn: 0.1-1.30%, Cr: 0.15-1.1%, Cu: 0.15-0.6%, Ti: 0.010-0.1%, Al: 0.003-0.05%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less, whole decarburized layer depth is 0.20 mm or less, and fracture reduction of area is 25% or more. It alternately may contain; C: 0.38-0.47%, Si: 1.9-2.5%, Mn: 0.6-1.3%, Ti: 0.05-0.15%, Al: 0.003-0.1%, and the balance including iron with inevitable impurities, wherein ferrite decarburized layer depth is 0.01 mm or less.

Owner:KOBE STEEL LTD

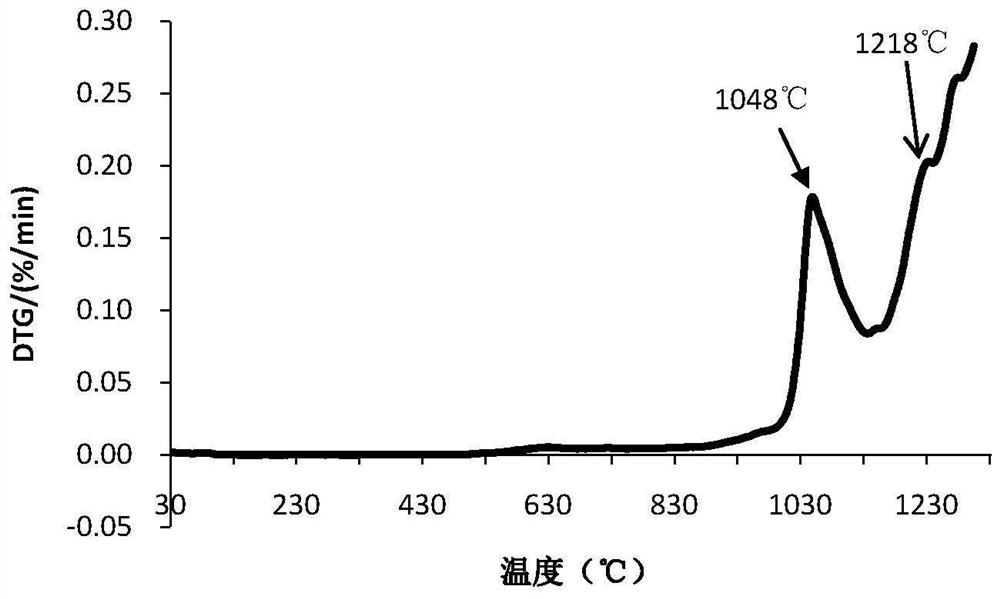

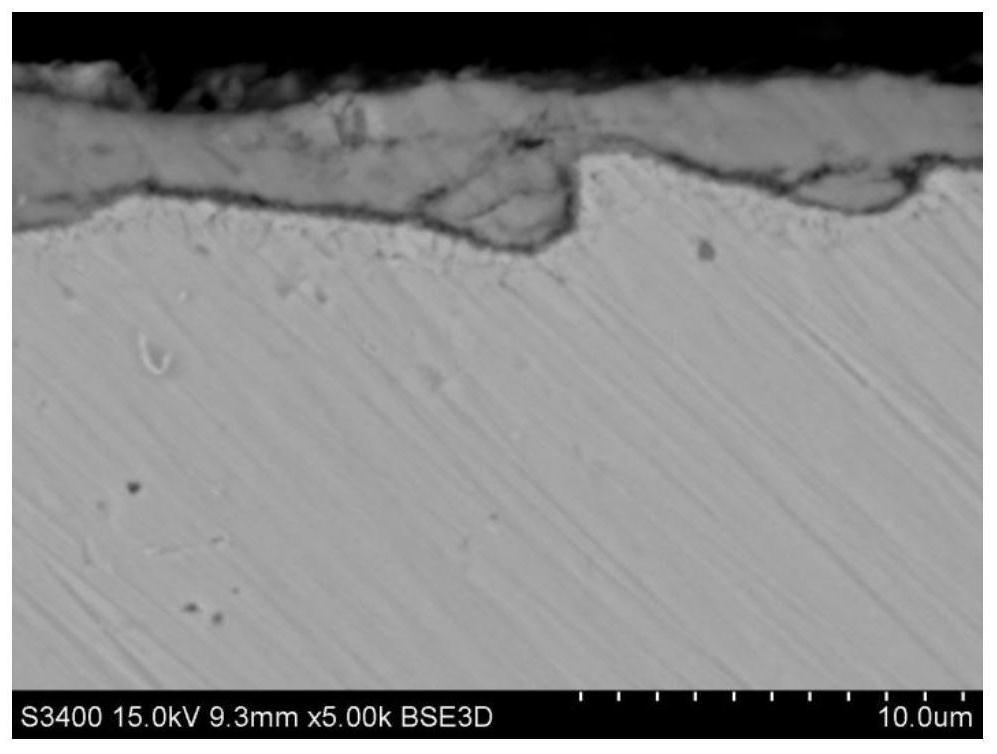

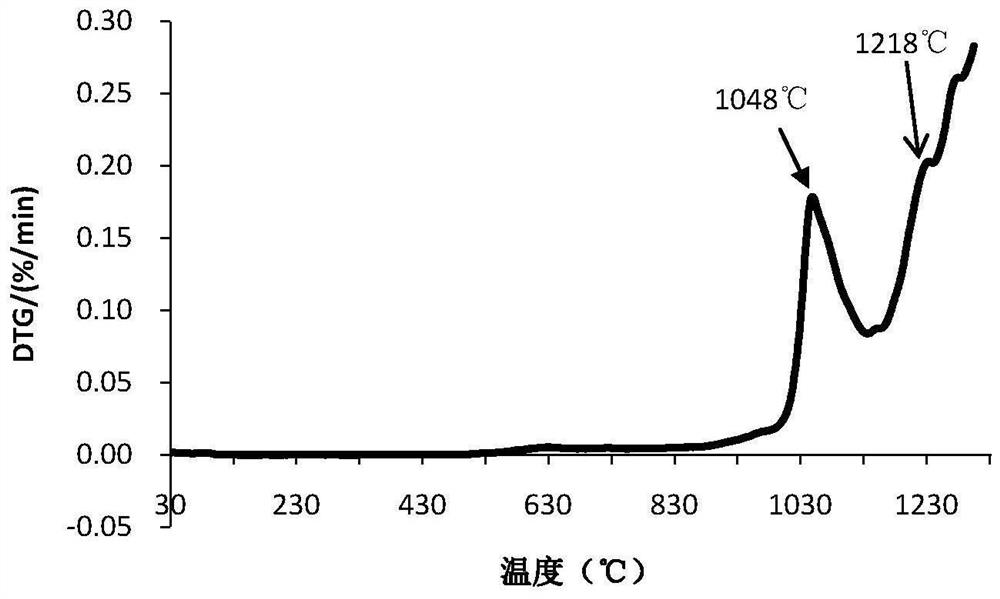

High-temperature surface carbon retaining isolation agent for medium-high-carbon steel and application method of high-temperature surface carbon retaining isolation agent

InactiveCN109022723AStop the spreadRealize carbon preservation and carbon increaseCarbon layerHigh carbon

The invention relates to a high-temperature surface carbon retaining isolation agent for medium-high-carbon steel and an application method of the high-temperature surface carbon retaining isolation agent. The high-temperature surface carbon retaining isolation agent comprises components including, by weight percent, 60%-85% of diopside, 1%-5% of nano silicon nitride, 1%-5% of nano chromium carbide, 5%-15% of aluminum ash powder, 6%-25% of potash water glass and 0.1%-0.5% of polyacrylamide, wherein the granularity of the nano silicon nitride and the granularity of the nano chromium carbide are100-500 nm, and the added water volume accounts for 60%-90% of the total weight. The above components are evenly mixed according to a mechanical grinding and mixing method to prepare the isolation agent with the granularity smaller than 100 microns. The isolation agent is suitable for high-temperature protection when a steel blank is heated at the temperature of 900-1,150 DEG C for 1-10 h, the isolation agent is sprayed to the surface of the normal-temperature steel blank, the thickness of the isolation agent ranges from 200 microns to 500 microns, a glass base protection film is formed in the temperature rise process of the isolation agent, and carbon oxygen mutual permeation of the surface of the base body is protected. After the protected steel blank is heated, the isolation agent andthe steel blank surface scales can be completely removed through high-pressure water descaling, the isolation agent achieves the function of carbon retaining, the rolled material surface decarburization layer depth is effectively reduced, the rolled material surface quality is improved, and the usage cost is low.

Owner:晋江市钫淦新材料科技有限公司

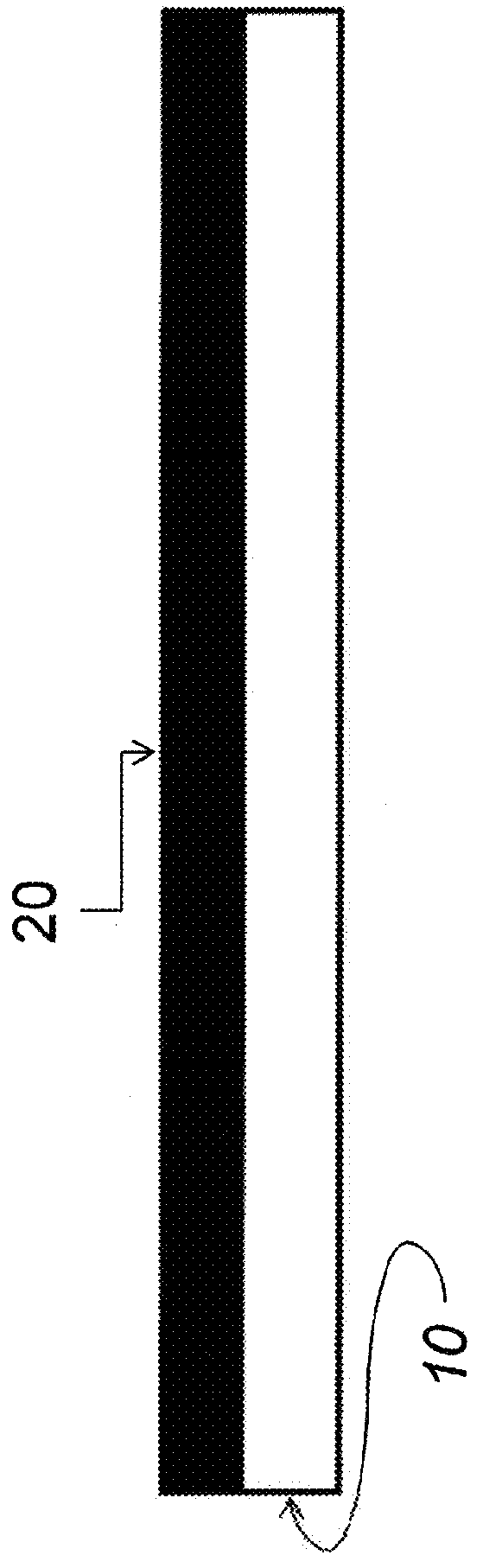

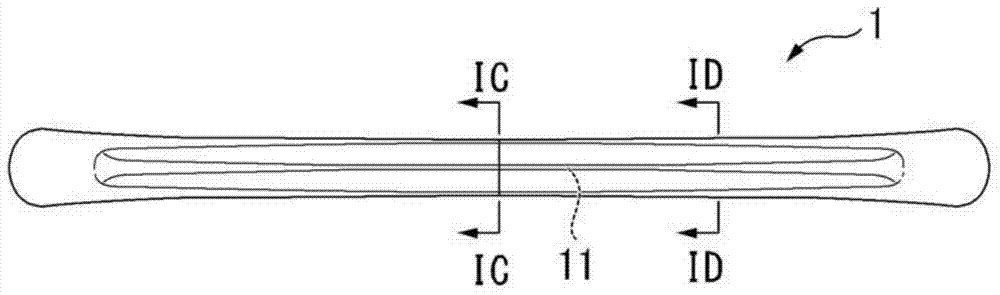

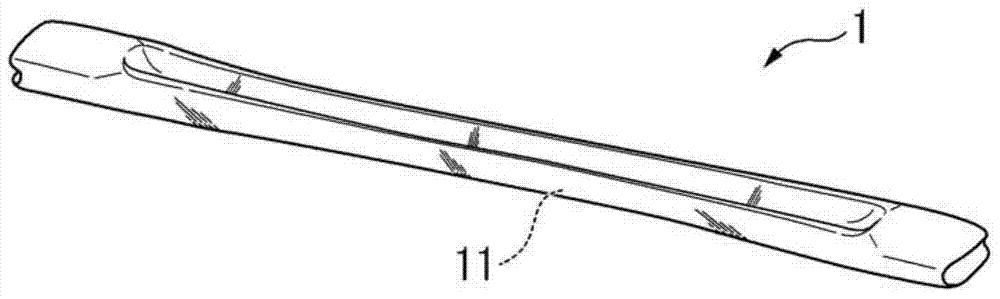

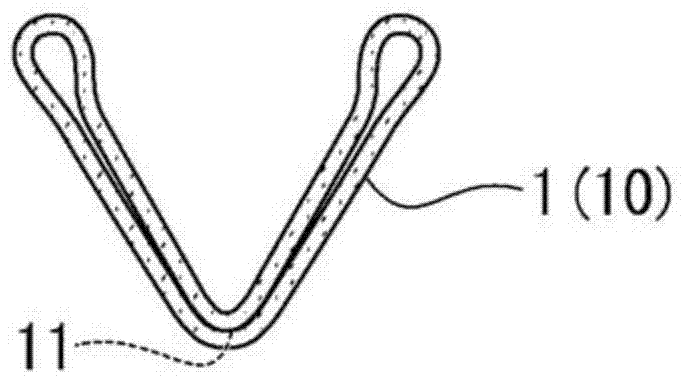

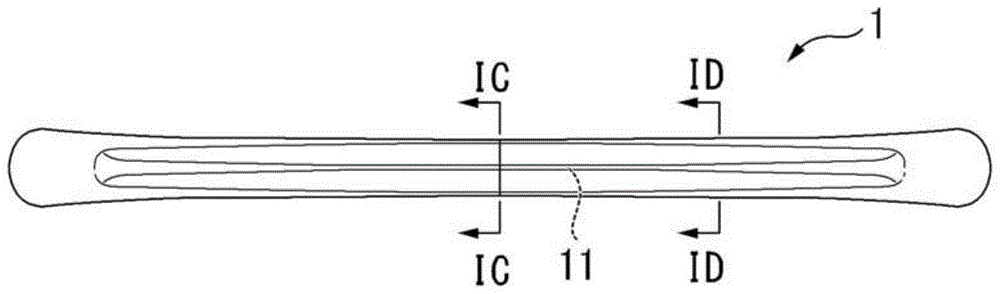

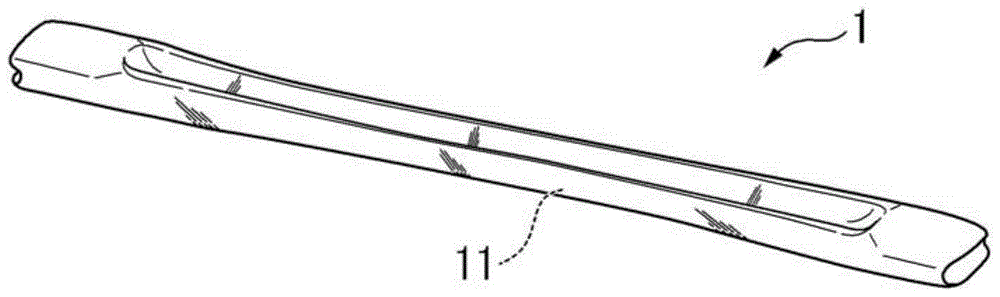

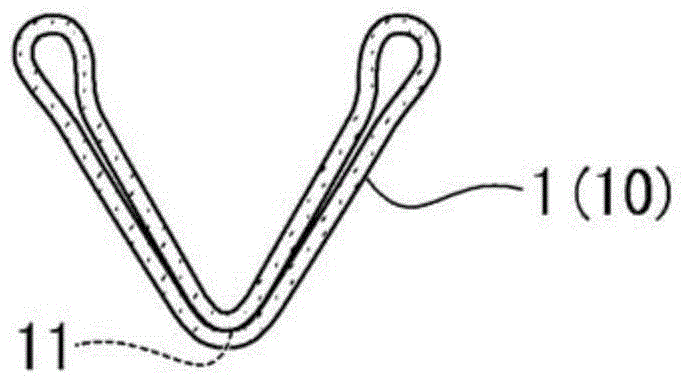

Hardened steel tube member, automobile axle beam using hardened steel tube member, and method for manufacturing hardened steel tube member

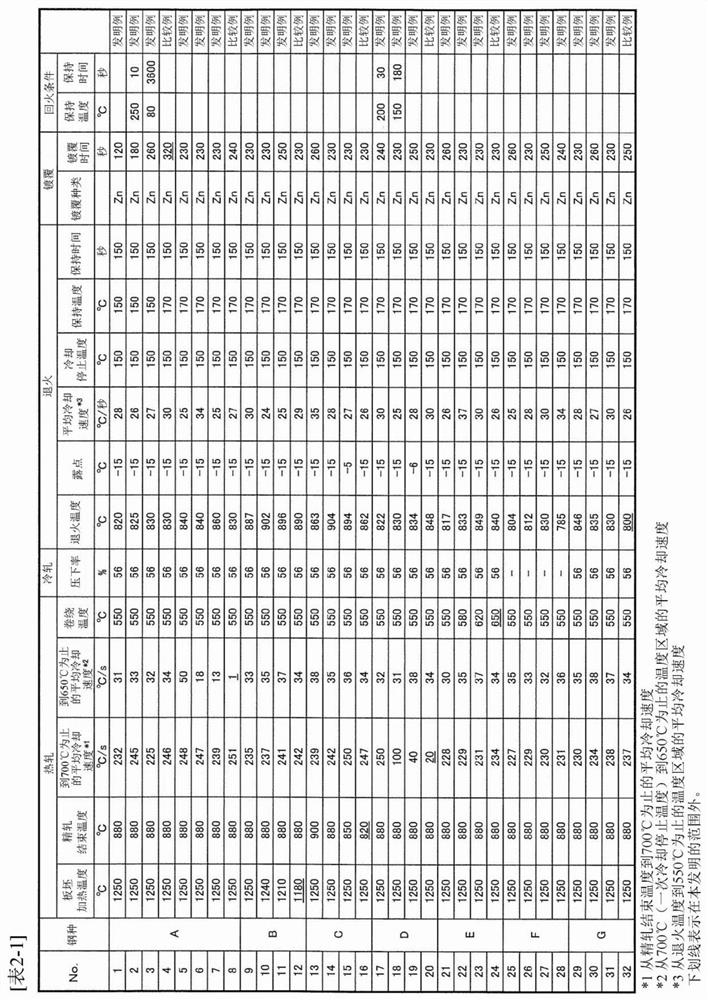

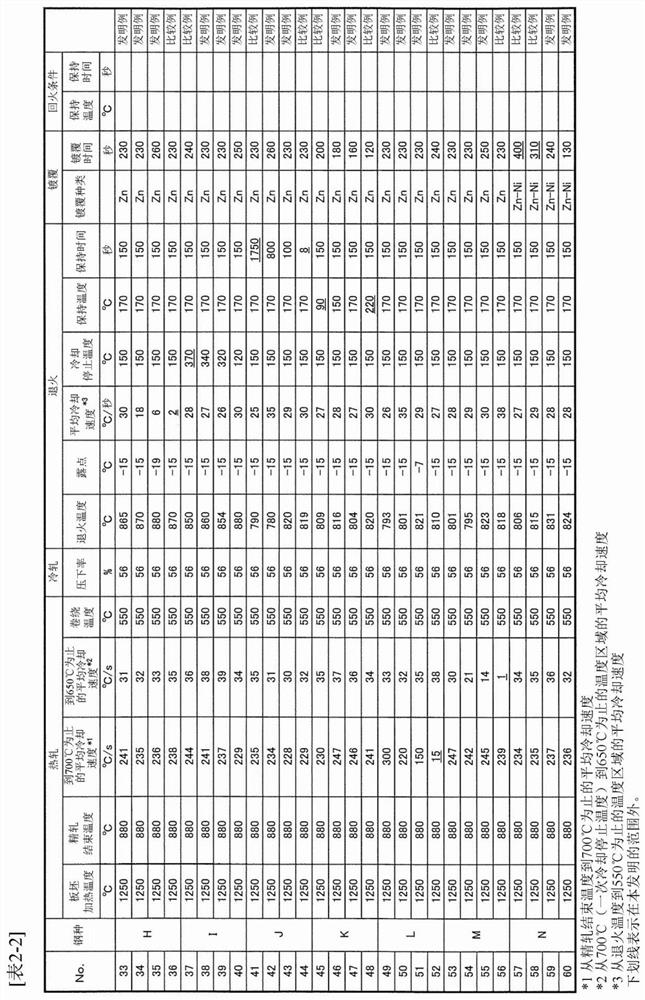

ActiveCN104508170AHigh hardnessExcellent fatigue propertiesHot-dipping/immersion processesFurnace typesSurface layerAlloy

The hardened steel tube member is formed from a GI zinc-coated steel tube. The cross-section, which is perpendicular to the longitudinal direction, at the center of the longitudinal direction of the GI zinc-coated steel tube is substantially a V-shape, the V-shape comprising a contacting section in which the inner surfaces of the GI zinc-coated steel tube contact each other. The contacting section is integrated by a Fe-Zn alloy phase. The micro Vickers hardness at a depth of 50 µm from the surface layer of the base metal is 95% or more of the micro Vickers hardness at a depth of 200 µm from the surface layer of the base metal.

Owner:NIPPON STEEL CORP

Quenched steel pipe member, automobile axle beam using the quenched steel pipe member, and method for manufacturing the quenched steel pipe member

ActiveCN104508170BHigh hardnessExcellent fatigue propertiesHot-dipping/immersion processesHardnessAlloy

The quenched steel pipe member of the present invention is formed of a GI galvanized steel pipe whose cross-section perpendicular to the longitudinal direction in the central portion of the GI galvanized steel pipe has a contact between the inner peripheral surfaces of the GI galvanized steel pipe. The contact part is roughly V-shaped, and the contact part is integrated by the Fe-Zn alloy phase, and the micro-Vickers hardness at a depth of 50 μm from the surface of the base metal is 200 μm from the surface of the base metal. More than 95% of the micro Vickers hardness.

Owner:NIPPON STEEL CORP

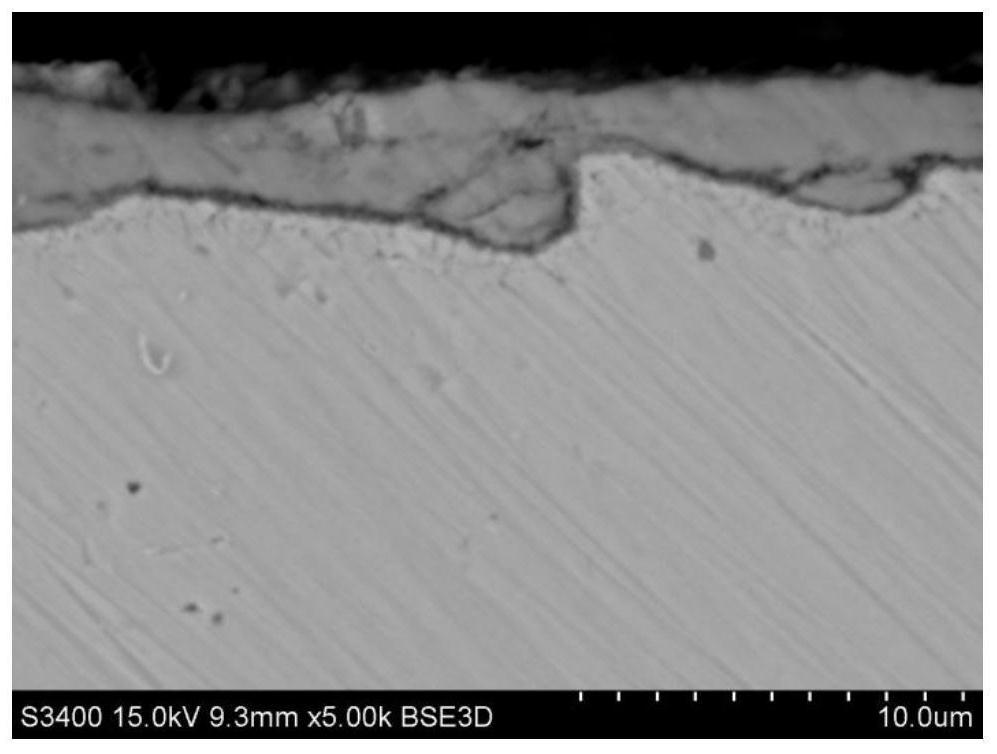

A protective coating for ultra-high-strength steel and a preparation method for the ultra-high-strength steel protective coating

ActiveCN109266061BPlay the role of bondingAct as a skeletonFireproof paintsAlkali metal silicate coatingsMaterials scienceArgon gas

The invention discloses a protective paint for ultra-high-strength steel and a preparation method of an ultra-high-strength steel protective coating. The preparation method includecomprises the following steps: preparing the paint; removing impurities from an ultrahigh-strength steel sheet; spraying the paint to the surface of the impurity-removed ultrahigh-strength steel sheet through atomization, wherein the spraying amount of the paint is 0.2-0.3 kg / m<2>; curing the painted ultrahigh-strength steel sheet at the temperature of 120-150 DEG C for 4-6 h; subjecting the painted ultrahigh-strength steel sheet to plasma oxidation at the temperature of 600-620 DEG C, simultaneously injecting argon and oxygen with the pressure of 30-50 MPa according to the volume ratio of 2:1 to 4:1 during plasma oxidation, and preserving the temperature for 30-60 min. The protective paint and the preparation method have the advantages that the preparation process is simple, the quality is stable, a good cutprotection effect and a high temperature protection effect are achieved, and the surface has a superhydrophobic property.

Owner:NANJING INST OF TECH +1

A kind of aluminum-containing high-strength steel and its preparation method and application

ActiveCN112195416BGuaranteed mechanical propertiesDoes not affect responseChemical compositionAluminum high

Owner:SHOUGANG CORPORATION +1

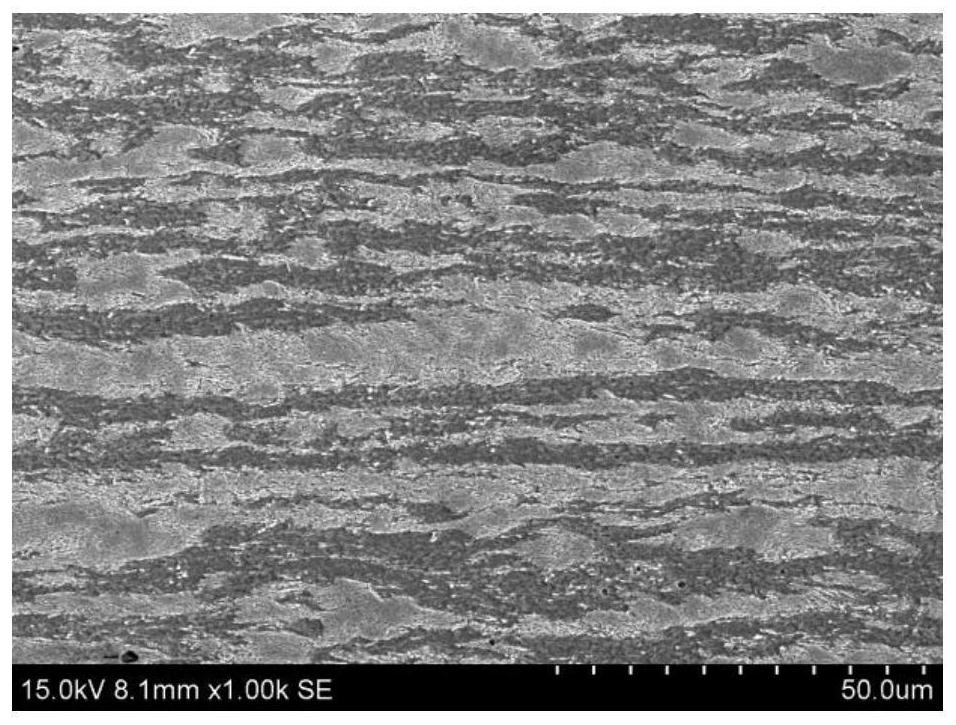

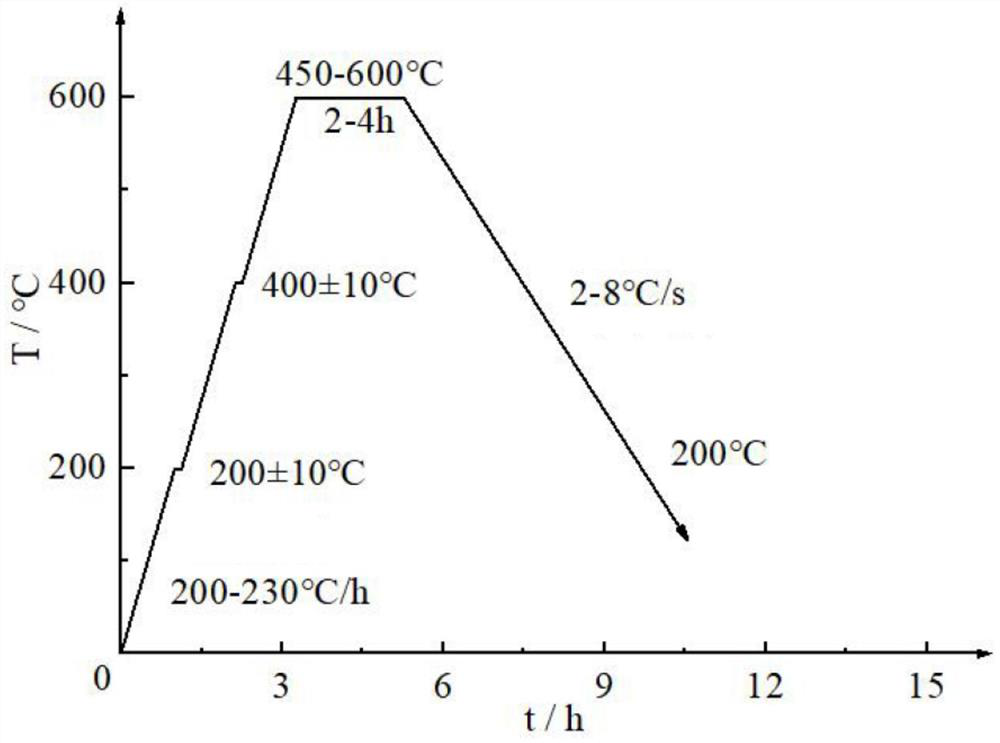

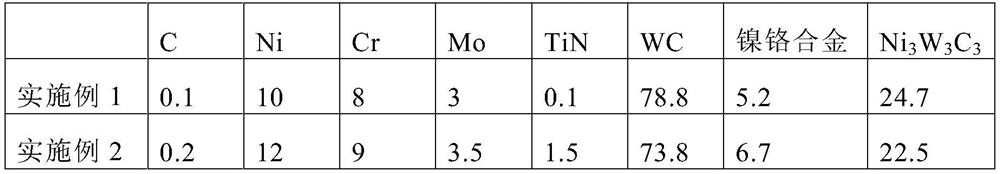

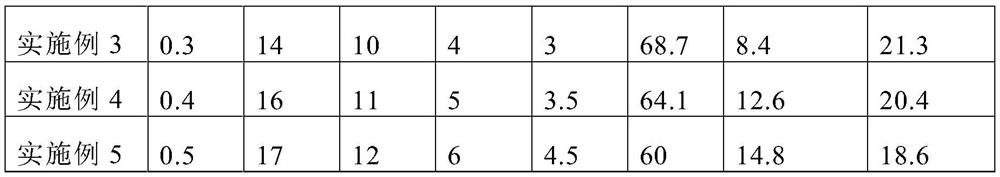

Wear-resistant shaft sleeve coating and preparation method thereof

PendingCN114763609AHigh hardnessImprove toughnessMetallic material coating processesIncreasing energy efficiencyMechanical engineeringMechanical property

The invention discloses a wear-resistant shaft sleeve coating and a preparation method thereof. The wear-resistant shaft sleeve coating comprises the following chemical components in percentage by weight: 0.1-0.5% of C, 10-17% of Ni, 8-12% of Cr, 3-6% of Mo, 0.1-4.5% of TiN and the balance of WC and inevitable impurities. The coating raw materials are proportioned according to the components, then laser cladding is carried out in a reverse synchronous powder feeding mode, a laser cladding layer is formed on the surface of a shaft sleeve, and the wear-resistant shaft sleeve coating is obtained after annealing heat treatment. By designing the comprehensive proportion of the components of the shaft sleeve coating, the laser cladding process and the heat treatment process, the mechanical property of the shaft sleeve coating is comprehensively improved, the service life of the shaft sleeve is effectively prolonged, and the problems that the shaft sleeve coating is prone to stripping, the service life of the shaft sleeve on a machine is short, and the field production efficiency is limited are solved; and a solid foundation is laid for improving the production efficiency and reducing the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-ductility, high-strength electro-galvanized steel sheet and manufacturing method thereof

ActiveCN112867807AInhibition of decarburizationIncrease the amount of fine carbidesHot-dipping/immersion processesFurnace typesElectrogalvanizationHydrogen content

Owner:JFE STEEL CORP

A kind of spring steel with good heat resistance and impact resistance and production method thereof

ActiveCN111690875BImprove heat resistanceGuaranteed room temperature performanceWire rodElectric arc furnace

Owner:MAANSHAN IRON & STEEL CO LTD

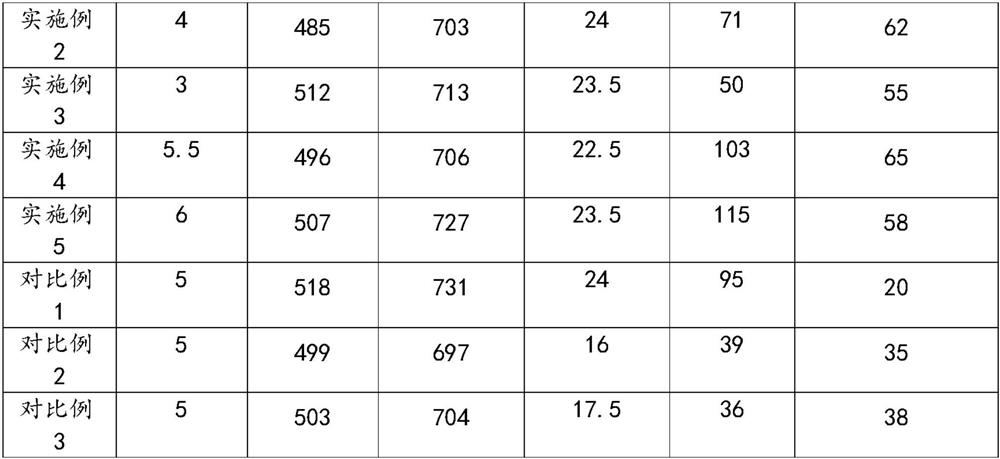

Preparation method of co-based high temperature binder cemented carbide

InactiveCN105349814BOvercome the adverse effects of high temperature mechanical propertiesComposition control with high precisionHigh energyAdhesive

The invention discloses a method for preparing Co-based high-temperature adhesive hard alloy. The method comprises the steps that firstly, CoCl2 6H2O, AlCl3 and deionized water are prepared into a solution, and WO3 powder is added to the solution; a (NH4)2C2O4 solution is added to turbid liquid in volume ratio; the solution is filtered and dried to obtain precursor powder; the dried powder is reduced under the hydrogen atmosphere condition; the reduced powder is subjected to high energy ball milling under argon protection to obtain Co-Al-W prealloy powder; WC and Co-Al-W are subjected to high energy ball milling after being matched, vacuum drying is carried out, and ball milling powder is obtained and placed in a mold for cold pressing forming; and a green ware body obtained after cold pressing forming is sintered, and finally a Co-based high-temperature adhesive hard alloy block is obtained. According to the Co-based high-temperature adhesive hard alloy prepared according to the method, the Vickers hardness is larger than or equal to 1,580 / kg mm<-2>, the bending strength is larger than or equal to 4,958 MPa, and the tensile strength at the temperature of 100 DEG C is larger than or equal to 4,376 MPa.

Owner:SHAANXI UNIV OF TECH

A heat treatment process of drill steel xgq25 with hardness gradient distribution

InactiveCN105821371BExtended service lifeGood match of strength and toughnessSolid state diffusion coatingThree stageRoom temperature

The invention relates to a heat treatment process of brazing tool steel XGQ25 with gradient hardness distribution; and the process can realize reasonable gradient hardness distribution of a carburized brazing tool from the surface to the basal body. The process comprises the following steps: the carburized brazing tool is quenched and insulated by 60 minutes at 800+-10 DEG C, and is cooled by three stages after the insulation is finished; firstly, the oil cooling is performed to reach 400+-10 DEG C; then, the furnace cooling is performed to reach 200 DEG C, and the cooling speed is 0.05-0.1 DEG C / s; and then, the air cooling is performed below 200 DEG C to reach the room temperature. The tempering insulation is performed by 120 minutes at 200 DEG C; and the air cooling is performed to reach the room temperature after the insulation is finished. Through actuation of the process, the carburized brazing tool forms a high-carbon martensite structure (HV640-660) with high surface hardness, a lower bainite structure (no-gap impact power of 115-120 J) with high center toughness and a lower bainite and low-carbon martensite complex-phase structure with a wider transition layer (width of 0.5-1.0 mm), so that excellent toughness matchability is obtained, and the service life of the brazing tool is effectively prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing Co-based high-temperature adhesive hard alloy

InactiveCN105349814AOvercome the adverse effects of high temperature mechanical propertiesComposition control with high precisionHigh energyAdhesive

The invention discloses a method for preparing Co-based high-temperature adhesive hard alloy. The method comprises the steps that firstly, CoCl2 6H2O, AlCl3 and deionized water are prepared into a solution, and WO3 powder is added to the solution; a (NH4)2C2O4 solution is added to turbid liquid in volume ratio; the solution is filtered and dried to obtain precursor powder; the dried powder is reduced under the hydrogen atmosphere condition; the reduced powder is subjected to high energy ball milling under argon protection to obtain Co-Al-W prealloy powder; WC and Co-Al-W are subjected to high energy ball milling after being matched, vacuum drying is carried out, and ball milling powder is obtained and placed in a mold for cold pressing forming; and a green ware body obtained after cold pressing forming is sintered, and finally a Co-based high-temperature adhesive hard alloy block is obtained. According to the Co-based high-temperature adhesive hard alloy prepared according to the method, the Vickers hardness is larger than or equal to 1,580 / kg mm<-2>, the bending strength is larger than or equal to 4,958 MPa, and the tensile strength at the temperature of 100 DEG C is larger than or equal to 4,376 MPa.

Owner:SHAANXI UNIV OF TECH

Furnace beam and vertical column fire-resistant thermal insulation lining structure of walking beam furnace for heating high-temperature oriented silicon steel and manufacturing method of structure

The invention discloses a furnace beam and vertical column fire-resistant thermal insulation lining structure of a walking beam furnace for heating high-temperature oriented silicon steel. The furnace beam and vertical column fire-resistant thermal insulation lining structure comprises a metal pipe forming a foundation of a furnace beam or a vertical column, wherein heat-resistant cushion blocks are arranged on the metal pipe forming the foundation of the furnace beam at intervals along the axis direction, metal anchoring parts are uniformly distributed on the outer wall of the metal pipe along the axial direction and the peripheral direction, a fire-resistant insulating layer is formed to cling to the outer wall of the metal pipe in a pouring manner and is combined with the metal anchoring parts, and the fire-resistant insulating layer is sequentially covered by a slag-bonding prevention layer and an anti-oxidation coating. As the heat preservation and slag-bonding prevention double-layer structure and the design of appropriate thickness are adopted by the furnace beam and vertical column fire-resistant thermal insulation lining structure of the walking beam furnace, the integrality of a thermal insulation lining is improved, and the comprehensive usability of the thermal insulation lining is improved.

Owner:武汉钢铁有限公司

Preparation method of ni-fe based high temperature binder phase cemented carbide

InactiveCN104593626BOvercome the adverse effects of high temperature mechanical propertiesComposition control with high precisionHigh energyFlexural strength

The invention discloses a method for preparing a Ni-Fe-based high-temperature binder phase hard alloy. The method comprises the following steps of firstly mixing nickel powder, iron powder, chromium powder, molybdenum powder and aluminum powder in a predetermined mass ratio and carrying out high-energy ball milling; carrying out ordinary ball milling on powder subjected to high-energy ball milling, tungsten carbide powder, titanium carbide powder and vanadium carbide powder to obtain a mixed powder; loading the prepared mixed powder into a mold and pressing by virtue of cold press to obtain a green body; carrying out sinter molding on the green body material under the protective atmosphere to finally obtain the Ni-Fe-based high-temperature binder phase hard alloy material. According to the method, Ni-Fe-based mechanical alloying powder instead of Co powder is used as a binder, and the prepared hard alloy has Vickers hardness equal to or greater than 1530 / kg.mm<-2>, flexural strength equal to or greater than 4880MPa and tensile strength equal to or greater than 4562MPa at 1000 DEG C.

Owner:SHAANXI UNIV OF TECH

Steel wire rod for bridge cables and manufacturing method thereof

Owner:JIANGSU YONGGANG GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com