Preparation method of co-based high temperature binder cemented carbide

A cemented carbide and high-temperature technology, which is applied in the field of preparation of high-temperature binder phase cemented carbide, can solve problems such as limiting application and shortening the service life of cemented carbide, and achieves high precision of composition control, strong process stability and repeatability, The effect of overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

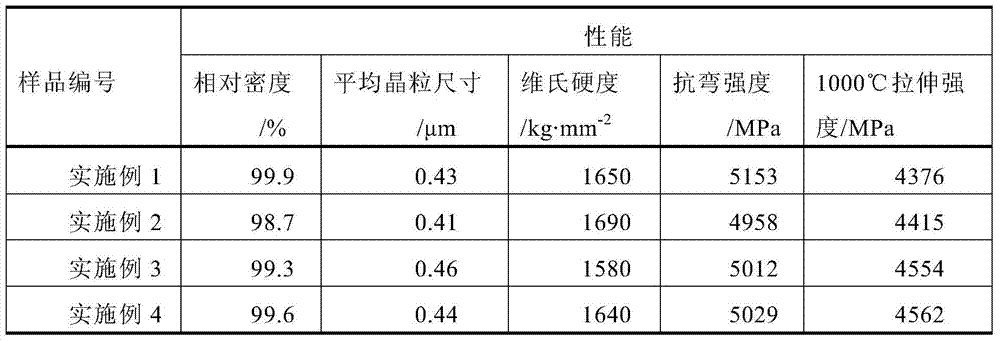

Examples

Embodiment 1

[0026] (1) In a vacuum glove box (vacuum degree 0.02MPa), take 88.7% CoCl by mass percentage 2 ·6H 2 O (cobalt chloride hexahydrate), 8.2% AlCl 3 (aluminum chloride) and 3.1% WO 3 (tungsten trioxide) powder; CoCl was mixed with a magnetic stirrer 2 ·6H 2 O, AlCl 3 and deionized water to form a solution with a concentration of 0.36mol / L, and add WO to the solution 3 powder, add concentration of 0.353mol / L (NH 4 ) 2 C 2 o 4 (ammonium oxalate) solution, the temperature of the water bath is 55°C at this time, and stirred for 1.5 hours.

[0027] (2) Filter the solution, and dry it in air at 120° C. for 2.5 hours with a blast drying oven to obtain a precursor powder at a heating rate of 13° C. / min; place the dried powder in a tube furnace (quartz tube, In a tube diameter of 60mm), reduce at 510°C, with a heating rate of 8°C / min, a cooling rate of 15°C / min, and keep warm for 2 hours.

[0028] (3) The reduced powder was high-energy ball milled under the protection of argon ...

Embodiment 2

[0032] (1) Weigh 82.5% CoCl by mass percentage 2 ·6H 2 O, 13.4% AlCl 3 and 4.1% WO 3 powder; CoCl was mixed with a magnetic stirrer 2 ·6H 2 O, AlCl 3 and deionized water to form a solution with a concentration of 0.36mol / L, and add WO to the solution 3 powder, add concentration of 0.375mol / L (NH 4 ) 2 C 2 o 4 (ammonium oxalate) solution, the temperature of the water bath is 55°C, and stirred for 2 hours.

[0033] (2) Filter the solution, and dry it in air at 120°C for 2.2 hours with a blast drying oven to obtain a precursor powder at a heating rate of 13°C / min; place the dry powder in a tube furnace (quartz tube, In a pipe diameter of 60mm), it was reduced at 495°C, the heating rate was 8°C / min, the cooling rate was 15°C / min, and the temperature was kept for 2.5 hours.

[0034] (3) The reduced powder was high-energy ball milled under the protection of argon for 11 hours, the speed of the ball mill was 400 rpm, the materials of the ball and the ball mill were stainle...

Embodiment 3

[0038](1) Weigh 86.5% CoCl by mass percentage 2 ·6H 2 O, 12.6% AlCl 3 and 0.9% WO 3 powder; CoCl was mixed with a magnetic stirrer 2 ·6H 2 O, AlCl 3 and deionized water to form a solution with a concentration of 0.36mol / L, and add WO to the solution 3 powder, add concentration of 0.324mol / L (NH 4 ) 2 C 2 o 4 (ammonium oxalate) solution, the temperature of the water bath is 55°C, and stirred for 2 hours.

[0039] (2) Filter the solution, and dry it in air at 120° C. for 2.3 hours with a blast drying oven to obtain a precursor powder at a heating rate of 13° C. / min; place the dried powder in a tube furnace (quartz tube, In a tube diameter of 60mm), reduce at 510°C, with a heating rate of 8°C / min, a cooling rate of 15°C / min, and keep warm for 3 hours.

[0040] (3) The reduced powder was high-energy ball milled under the protection of argon for 12 hours, the speed of the ball mill was 360 rpm, the materials of the balls and the ball mill pot were all stainless steel, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com