A kind of multi-component cemented carbide and its preparation method

A kind of cemented carbide and multi-element technology, which is applied in the field of WC-3C2---Co multi-element cemented carbide and its preparation, which can solve the problems of increased difficulty in adjusting the performance of multi-element cemented carbide and complicated influence mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of WC-(Ti x ,Cr 1-x ) 3 C 2 -(Fe, Cr)-(Ni, Cu)-Co multi-component cemented carbide preparation method, comprises the following steps:

[0027] WC powder, (Ti x ,Cr 1-x ) 3 C 2 Powder, Fe-Cr pre-alloyed powder, Ni-Cu pre-alloyed powder and Co powder are mixed according to the mass ratio of 63~75:4~7:10~15:3~8:5~10, and the mixed powder is sequentially WC-(Ti x ,Cr 1-x ) 3 C 2 -(Fe,Cr)-(Ni,Cu)-Co multi-component cemented carbide; where, 0.5≤x≤1;

[0028] The mass ratio of Fe and Cr in the Fe-Cr pre-alloyed powder is 89-97:3-11, and the mass ratio of Ni and Cu in the Ni-Cu pre-alloyed powder is 70-89:11-30.

[0029] The present invention will WC powder, (Ti x ,Cr 1-x ) 3 C 2 The powder, the Fe-Cr pre-alloyed powder, the Ni-Cu pre-alloyed powder and the Co powder are mixed in a mass ratio of 63-75:4-7:10-15:3-8:5-10. In the present invention, the WC powder, (Ti x ,Cr 1-x ) 3 C 2 The particle size of the powder, Fe-Cr pre-al...

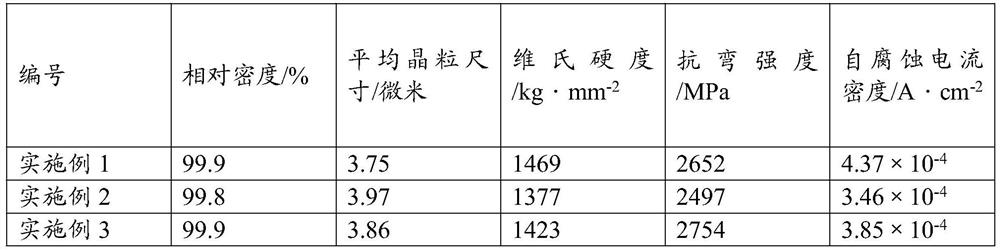

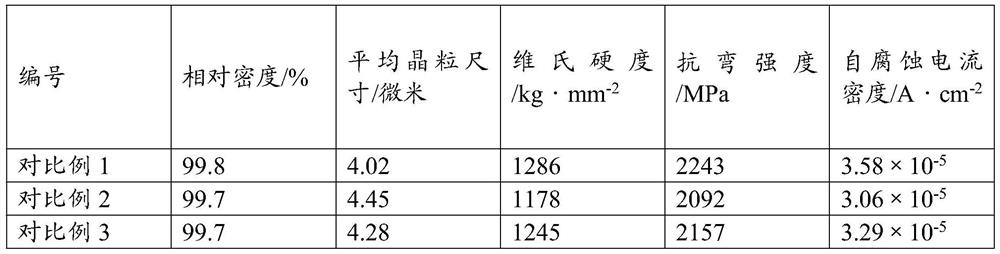

Embodiment 1

[0056] A WC-(Ti x ,Cr 1-x ) 3 C 2 -(Fe,Cr)-(Ni,Cu)-Co multi-component cemented carbide and its preparation method: the steps are as follows:

[0057] (1) Weigh 73.65% Ni(CH 3 COO) 2 powder and 26.35% CuCl 2 2H 2 O powder, Ni(CH 3 COO) 2 Powder, CuCl 2 2H 2 O powder and deionized water are made into 200L of a solution with a concentration of 0.32mol / L. After fully stirring in a constant temperature water bath at 55°C, add an excess of sodium oxalate-NaOH mixed solution with a concentration of 0.15mol / L to the solution, and Add 3% positively charged cetyltrimethylammonium bromide surfactant, then continue to stir for 3h, filter and dry the solution to obtain the precursor powder, then place it in a hydrogen furnace at 520°C for 6h and heat reduction for 6h. After the furnace is cooled, ball mill the reduced powder for 7 hours under the protection of argon gas. The ball mill equipment is a planetary ball mill. -Cu pre-alloyed powder, and then perform high-frequency im...

Embodiment 2

[0063] A WC-(Ti x ,Cr 1-x ) 3 C 2 -(Fe,Cr)-(Ni,Cu)-Co multi-component cemented carbide and its preparation method: the steps are as follows:

[0064] (1) Weigh 73.65% Ni(CH 3 COO) 2 powder and 26.35% CuCl 2 2H 2 O powder, Ni(CH 3 COO) 2 Powder, CuCl 2 2H 2 O powder and deionized water are made into 200L of a solution with a concentration of 0.32mol / L. After fully stirring in a constant temperature water bath at 50°C, add an excess of sodium oxalate-NaOH mixed solution with a concentration of 0.1mol / L to the solution, and Add 3.5% positively charged hexadecyltrimethylammonium bromide surfactant, then continue to stir for 3h, filter the solution, dry to obtain the precursor powder, and then place it in a hydrogen furnace at 520°C for heating and reduction for 6h, After cooling with the furnace, ball mill the reduced powder for 7 hours under the protection of argon gas. The ball mill equipment is a planetary ball mill. Ni-Cu pre-alloyed powder is then subjected to hig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com