Preparation method of ni-fe based high temperature binder phase cemented carbide

A technology of cemented carbide and binder phase, which is applied in the field of preparation of cemented carbide materials, can solve the problems of shortening the service life of cemented carbide and limiting applications, and achieves high precision in composition control, strong process stability and repeatability, and overcomes the The effect of bad influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

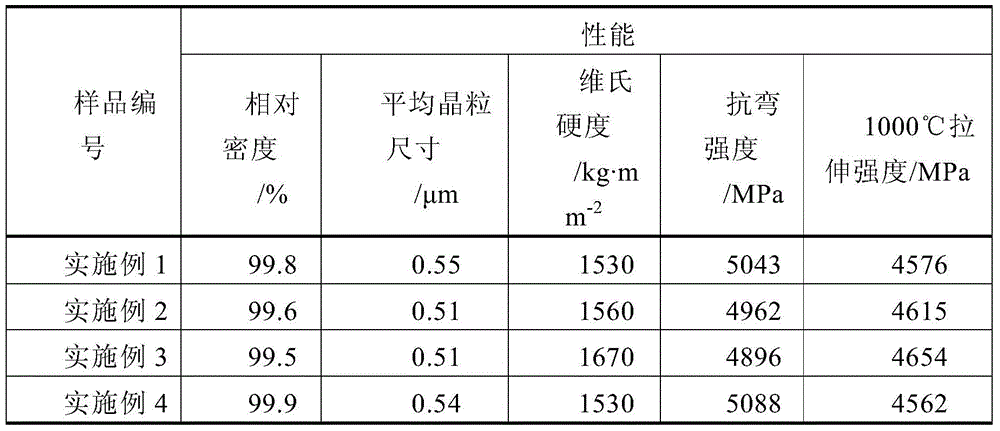

Examples

Embodiment 1

[0022] First, pre-mix nickel powder, iron powder, chromium powder, molybdenum powder and aluminum powder according to the mass percentage 36:34:18:6:6 for 1.5 hours (the pre-mixing equipment is a three-dimensional vortex mixer with a speed of 51 rpm) , and then the premixed powder was high-energy ball milled under the protection of argon atmosphere for 18 hours, the spindle speed of the ball mill was 250 rpm, the ball milling medium was absolute ethanol, the materials of the balls and the ball milling tank were all stainless steel, and the powder, balls, and absolute ethanol The mass ratio is 1:18:0.3, and the ball mill powder is taken out and dried in a vacuum oven at 150°C for 2.5 hours. Weigh WC, TiC, VC and Ni-Fe based high-energy ball mill powder according to the mass percentage of 74:18:0.2:7.8, put it into a ball mill tank under the protection of argon atmosphere, and carry out ordinary ball milling for 25 hours, using a planetary ball mill with a ball mill speed of 170 ...

Embodiment 2

[0025] First, nickel powder, iron powder, chromium powder, molybdenum powder and aluminum powder are pre-mixed for 1.5 hours according to the mass percentage of 38:33:19:7:3, and then the pre-mixed powder is high-energy ball milled under the protection of argon atmosphere for 18 hours. The spindle speed is 280 rpm, the mass ratio of powder, balls, and absolute ethanol is 1:21:0.3, the ball milled powder is taken out and placed in a vacuum drying oven at 150°C for 2.5 hours; it is weighed according to the mass percentage of 72:17.7:0.3:10 Take WC, TiC, VC and Ni-Fe based high-energy ball mill powders, put them into a ball mill tank under the protection of argon atmosphere and carry out ordinary ball milling for 25 hours, the speed of the ball mill is 190 rpm, and the ball-to-material ratio is 15:1.

[0026] Put the ball mill powder into a cold press mold and press it into a green body in a cold press with a pressing force of 230MPa; under the protection of an argon atmosphere, p...

Embodiment 3

[0028] First, pre-mix nickel powder, iron powder, chromium powder, molybdenum powder and aluminum powder according to the mass percentage 34:36:16:8:6 for 1.5 hours, and then high-energy ball mill the pre-mixed powder for 18 hours under the protection of argon atmosphere. The spindle speed is 260 rpm, the mass ratio of powder, balls, and absolute ethanol is 1:16:0.3, the ball milled powder is taken out and placed in a vacuum oven at 150°C for 2.5 hours; it is weighed according to the mass percentage of 73:18:0.2:8.8 Take WC, TiC, VC and Ni-Fe based high-energy ball mill powders, put them into a ball mill tank under the protection of argon atmosphere, and carry out ordinary ball milling for 25 hours. The ball mill speed is 180 rpm, and the ball-to-material ratio is 15:1.

[0029] Put the ball mill powder into a cold press mold and press it into a green body in a cold press with a pressing force of 230 MPa; under the protection of an argon atmosphere, put the green body into a hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com