A high temperature resistant high strength wc-co-ti 3 sic 2 Preparation method of cemented carbide material

A technology of wc-co-ti3sic2 and cemented carbide, which is applied in the field of preparation of high-temperature-resistant and high-strength WC-Co-Ti3SiC2 cemented carbide materials, can solve problems such as limiting applications and shortening the service life of WC-Co cemented carbide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

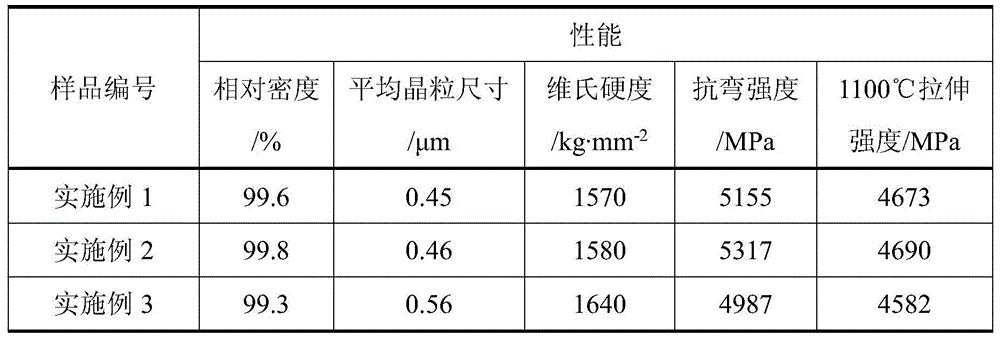

Embodiment 1

[0026] First, pre-mix titanium powder, silicon powder, graphite powder and aluminum powder according to the molar mass ratio (2.8:1.3:2.1:0.27) for 1 hour, then ball mill the pre-mixed powder for 12 hours under the protection of argon atmosphere, and the spindle speed of the ball mill is 300 RPM, filling factor 0.35, grinding ball material is cemented carbide. Under the protection of argon atmosphere, the ball-milled powder is sintered to make Ti 3 SiC 2 -TiC composite powder, sintering temperature 1480°C, holding time 2.2 hours, heating rate 5°C / min, cooling rate 15°C / min;

[0027] Take out Ti 3 SiC 2 -TiC composite powder, ground into a fine powder with a particle size of 0.45 μm, and mixed with tungsten carbide powder, cobalt powder, niobium carbide powder and vanadium carbide powder in a mass ratio (2:90:7.7:0.1:0.2) for 1 hour, mixed After ball milling for 14 hours, the spindle speed of the ball mill is 300 rpm, the filling factor is 0.5, and the ball material is ceme...

Embodiment 2

[0030]First, pre-mix titanium powder, silicon powder, graphite powder and aluminum powder according to the molar mass ratio (2.8:1.3:2.1:0.27) for 1 hour, then ball mill the pre-mixed powder for 12 hours under the protection of argon atmosphere, and the spindle speed of the ball mill is 300 RPM, filling factor 0.35, grinding ball material is cemented carbide. Under the protection of argon atmosphere, the ball-milled powder is sintered to make Ti 3 SiC 2 -TiC composite powder, sintering temperature 1480°C, holding time 2.2 hours, heating rate 5°C / min, cooling rate 15°C / min;

[0031] Take out Ti 3 SiC 2 - TiC composite powder, ground into a fine powder with a particle size of 0.45 μm, and mixed with tungsten carbide powder, cobalt powder, niobium carbide powder and vanadium carbide powder in a mass ratio (4:89:6.65:0.15:0.2) for 1 hour, mixed After ball milling for 14 hours, the spindle speed of the ball mill is 320 rpm, the filling coefficient is 0.4, and the ball material ...

Embodiment 3

[0034] First, pre-mix titanium powder, silicon powder, graphite powder and aluminum powder according to the molar mass ratio (2.8:1.3:2.1:0.27) for 1 hour, then ball mill the pre-mixed powder for 12 hours under the protection of argon atmosphere, and the spindle speed of the ball mill is 300 RPM, filling factor 0.4, grinding ball material is cemented carbide. Under the protection of argon atmosphere, the ball-milled powder is sintered to make Ti 3 SiC 2 -TiC composite powder, sintering temperature 1480°C, holding time 2.2 hours, heating rate 5°C / min, cooling rate 15°C / min;

[0035] Take out Ti 3 SiC 2 -TiC composite powder, ground into a fine powder with a particle size of 0.45 μm, and mixed with tungsten carbide powder, cobalt powder, niobium carbide powder and vanadium carbide powder in a mass ratio (6:87:6.45:0.3:0.25) for 1 hour, mixed After ball milling for 14 hours, the spindle speed of the ball mill is 350 rpm, the filling coefficient is 0.35, and the ball material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com