ODS ferritic stainless steel fuel cladding tube and preparation method thereof

A ferrite and ODS technology, applied in the direction of reactor fuel elements, manufacturing tools, heat treatment equipment, etc., can solve the problem that ODS steel cladding pipes cannot be applied to small special reactors with outlet temperature, and achieve long-term reliable mechanical strength and oxidation/corrosion resistance , good surface quality, excellent high temperature long-term strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

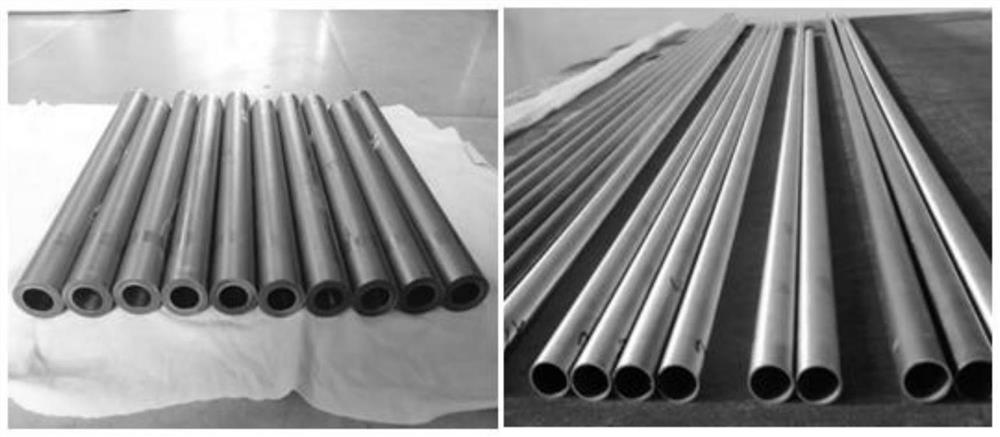

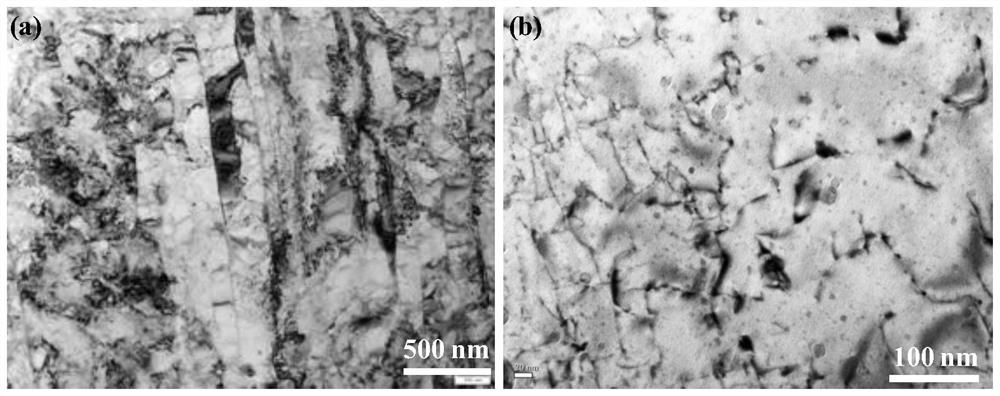

[0047] On the other hand, an embodiment of the present invention provides a method for preparing a cladding tube, including: gas atomization pulverization→powder mechanical ball milling→powder suction and sealing→powder solidification molding→rod billet hot forging forming→pipe billet piercing forming → Multi-pass cold rolling + intermediate annealing → heat treatment to obtain the final desired structure.

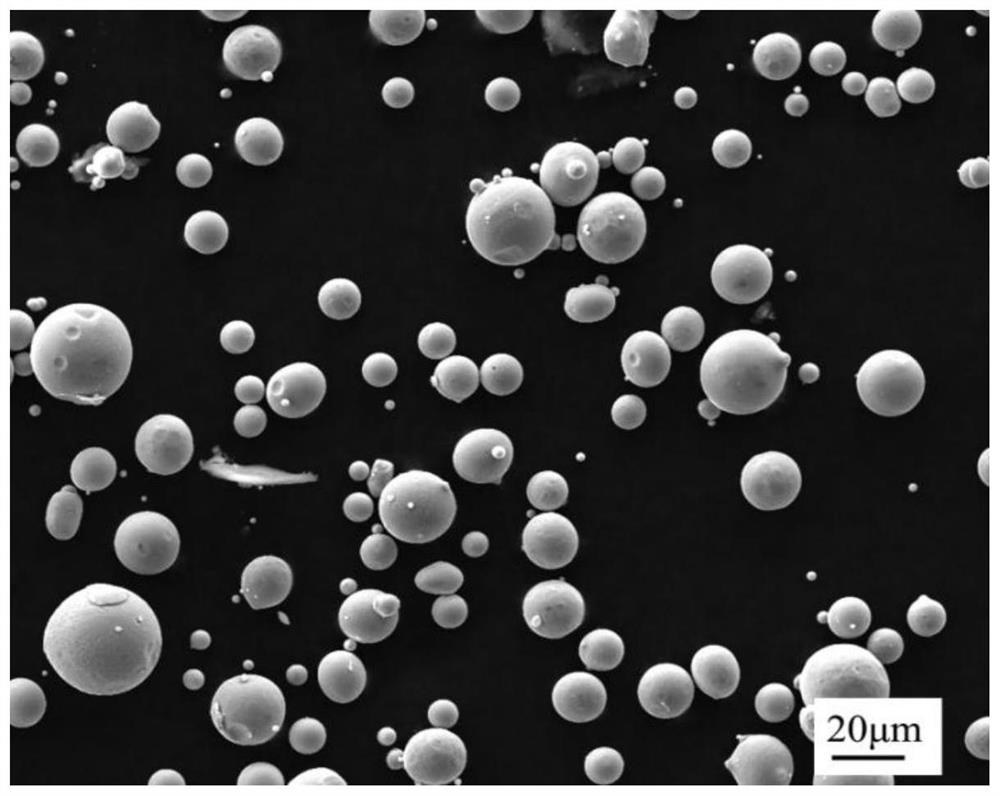

[0048] Further, the pre-alloyed powder of ODS steel with the designed composition was prepared by gas atomization method. The particle size of the pre-alloyed powder obtained by gas atomization pulverization is ≤150 μm, and the protective atmosphere is high-purity argon with volume purity ≥99.99%.

[0049] Furthermore, in order to realize the alloying of the powder and the uniformity of the structure and composition of the material, the method of mechanical ball milling is adopted, and the process conditions of the mechanical ball milling of the powder are designed as foll...

Embodiment 1

[0059] In this example, the composition of the ODS steel for preparing the ferritic stainless steel fuel cladding tube is: Cr: 12.13%, W: 1.98%, Mn: 0.47%, V: 0.17%, Y 2 o 3 : 0.35%, Ti: 0.41%, C: 0.011%, N: 0.008%, Fe balance and impurities.

[0060] The preparation process is as follows:

[0061] (1) Gas atomization powder production: ODS steel alloy powder was prepared by gas atomization method, the atomization gas pressure was 4.0 MPa, and the protective atmosphere was argon gas with a volume purity of 99.99%.

[0062] (2) Powder mechanical ball milling: Atomized powder with a particle size of ≤150 μm was selected for mechanical ball milling. The ball milling atmosphere was argon gas with a volume purity of 99.99%, the mass ratio of balls to materials was 10:1, the ball milling time was 48 hours, and the rotational speed was 240 r / min.

[0063] (3) Powder pumping and sealing: keep warm at 300°C for 2 hours, and at the same time use a molecular pump to pump air until the ...

Embodiment 2

[0069] In this embodiment, the alloy composition of ODS steel is: Cr: 12.25%, W: 1.93%, Y 2 o 3 : 0.35%, Ti: 0.37, C: 0.01%, N: 0.012%; Fe balance and impurities.

[0070] The difference between the cladding tube preparation process and Example 1 is that it lacks the hot isostatic pressing solidification molding process, and the ball mill powder obtained through the air extraction and sealing process is directly prepared into a billet by hot forging. 1 is the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com