A kind of nylon 6 composition with anti-aging performance and preparation method thereof

An anti-aging and composition technology, applied in the field of nylon 6 composition and its preparation, can solve the problems of cracking, brittleness, decrease in tensile strength and elongation, etc. Scratch and odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

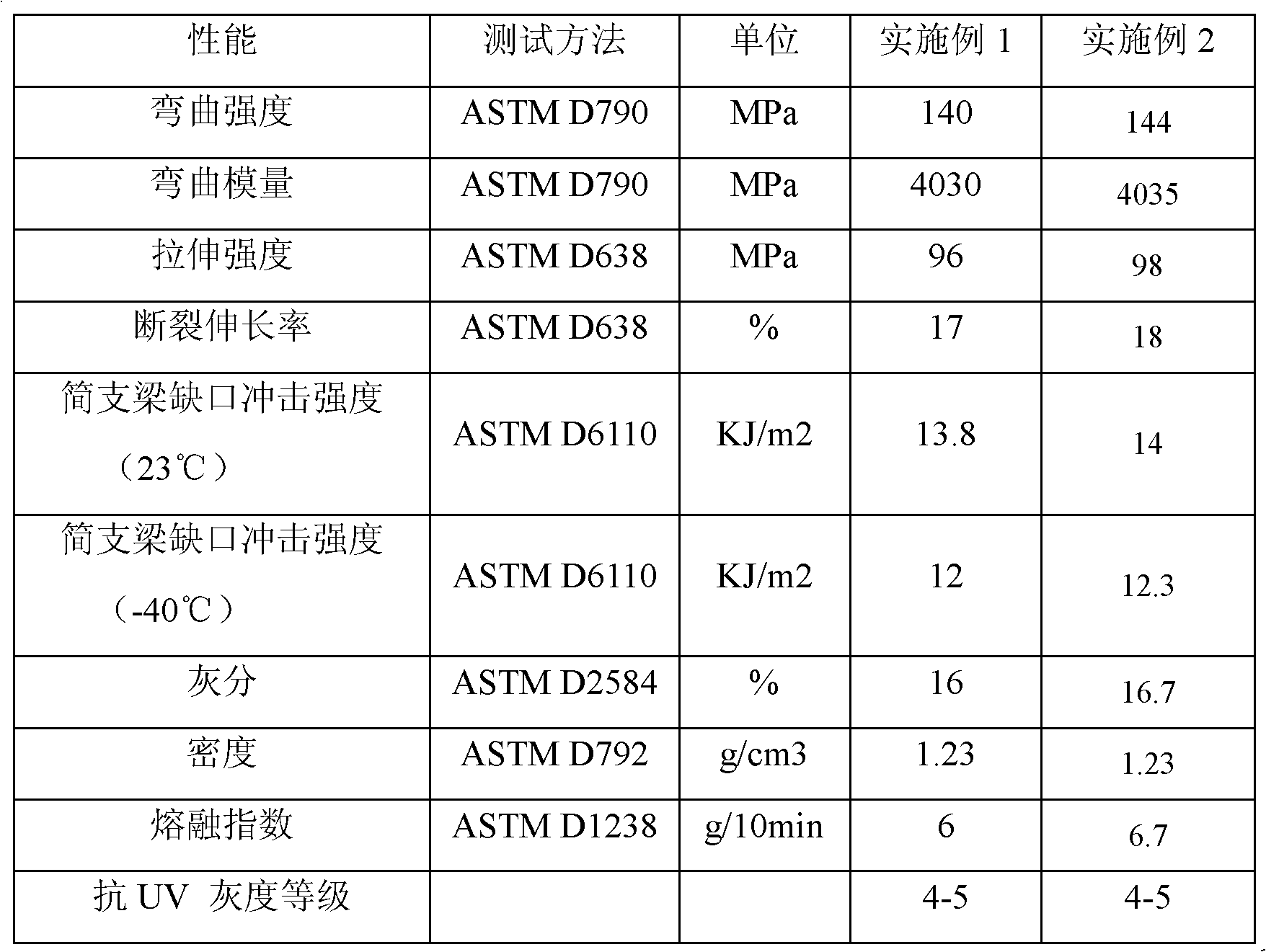

Embodiment 1

[0052] (1) Dry nylon 6 resin at 90-100°C for 3-4 hours;

[0053] (2) Weigh 75.5% of nylon 6 resin, 5.5% of polyethylene resin, 2.5% of maleic anhydride grafted ethylene-octene copolymer, 0.6% of anti-aging additive UV3035 / UV4045 / UV5050 (1:1:1), Antioxidant 1098 / 168 (1:1) 0.4%, lubricant AC-540A 0.5%;

[0054] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0055] (4) Add the mixed material into the hopper of the twin-screw extruder;

[0056](5) Add glass fibers with a mass fraction of 15% from the exhaust port of the extruder, melt and blend, extrude and granulate to form composite materials. Among them, the temperature settings of each section of the twin-screw extruder are: the temperature of the first zone of the twin-screw extruder is 180-220°C, the temperature of the second zone is 200-240°C, the temperature of the third zone is 220-250°C, the temperature of the fourth zone is 220-240°C, and the temperature of the fifth zone The ...

Embodiment 2

[0058] (1) Dry nylon 6 resin at 90-100°C for 3-4 hours;

[0059] (2) Weigh 76.1% of nylon 6 resin, 5.5% of polyethylene resin, 2.5% of maleic anhydride grafted ethylene-octene copolymer, 20.4% of anti-aging additive PolyAdHS, and 0.5% of lubricant AC-540A;

[0060] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0061] (4) Add the mixed material into the hopper of the twin-screw extruder;

[0062] (5) Add glass fibers with a mass fraction of 15% from the exhaust port of the extruder, melt and blend, extrude and granulate to form composite materials. Among them, the temperature settings of each section of the twin-screw extruder are: the temperature of the first zone of the twin-screw extruder is 180-220°C, the temperature of the second zone is 200-240°C, the temperature of the third zone is 220-250°C, the temperature of the fourth zone is 220-240°C, and the temperature of the fifth zone The temperature is 220-240°C, the temperature in ...

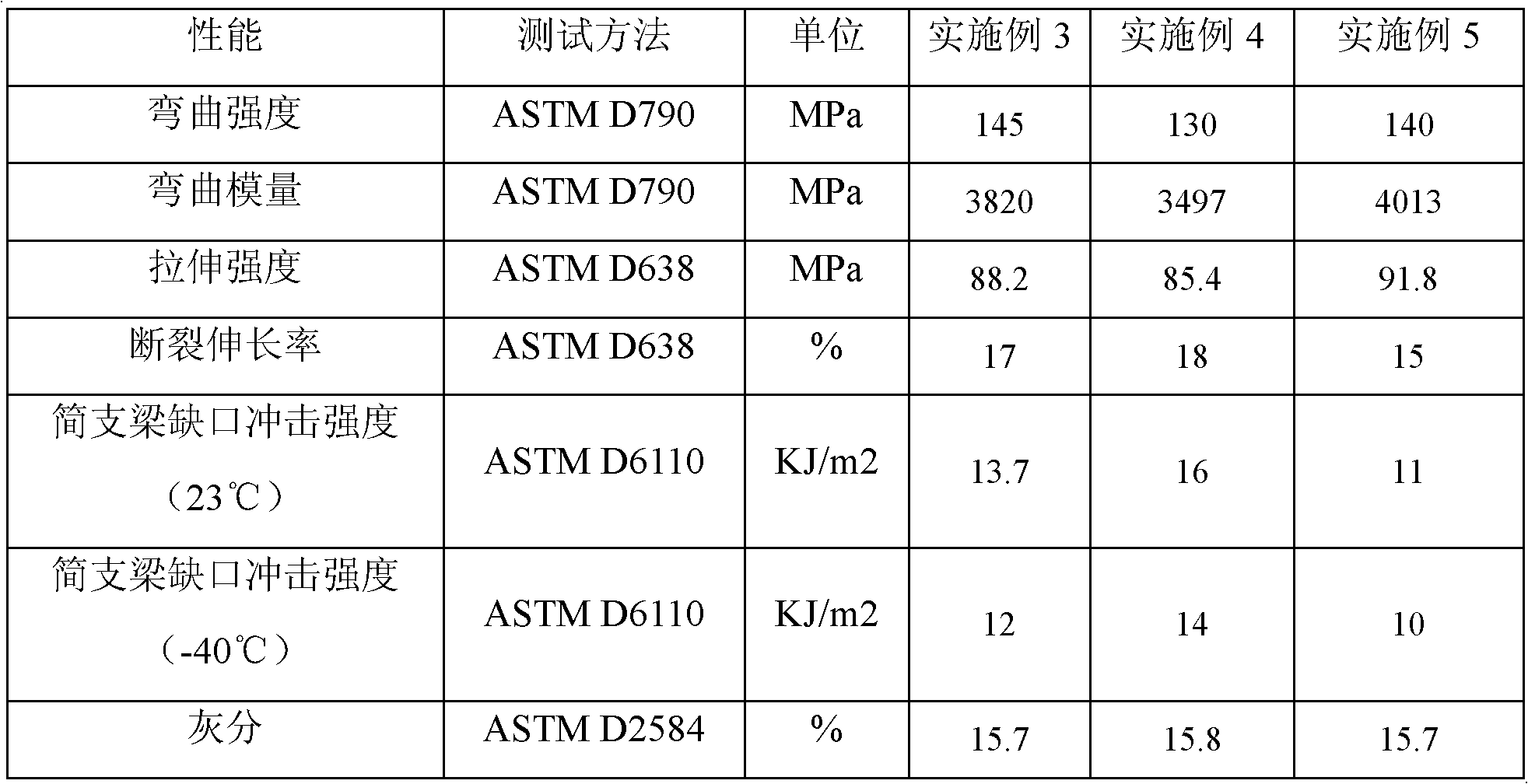

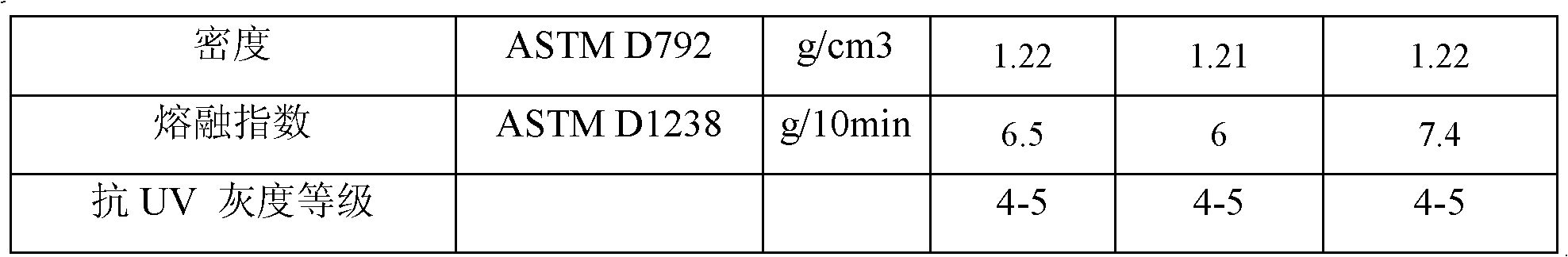

Embodiment 3

[0066] (1) Dry nylon 6 resin at 90-100°C for 3-4 hours;

[0067] (2) Weigh 75.5% of nylon 6 resin, 5.5% of polyethylene resin, 2.5% of maleic anhydride grafted ethylene-propylene copolymer, 0.6% of anti-aging additive UV3035 / UV4045 / UV5050 (1:1:1), anti-aging Oxygen agent 1098 / 168 (1:1) 0.4%, lubricant AC-540A 0.5%;

[0068] (3) Stir the material weighed in the above step (2) in a high-speed mixer for 3-5min;

[0069] (4) Add the mixed material into the hopper of the twin-screw extruder;

[0070] (5) Add glass fibers with a mass fraction of 15% from the exhaust port of the extruder, melt and blend, extrude and granulate to form composite materials. Among them, the temperature settings of each section of the twin-screw extruder are: the temperature of the first zone of the twin-screw extruder is 180-220°C, the temperature of the second zone is 200-240°C, the temperature of the third zone is 220-250°C, the temperature of the fourth zone is 220-240°C, and the temperature of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com