A kind of mg-gd-y-nd high strength and toughness rare earth magnesium alloy and preparation method thereof

A mg-gd-y-nd, rare earth magnesium technology, applied in the field of alloys, can solve the problems of restricting the development and application of alloys, high preparation difficulty and cost, and large hot cracking tendency of alloys, so as to reduce internal structure defects and optimize casting molding. and extrusion molding process, the effect of simplifying alloy species

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

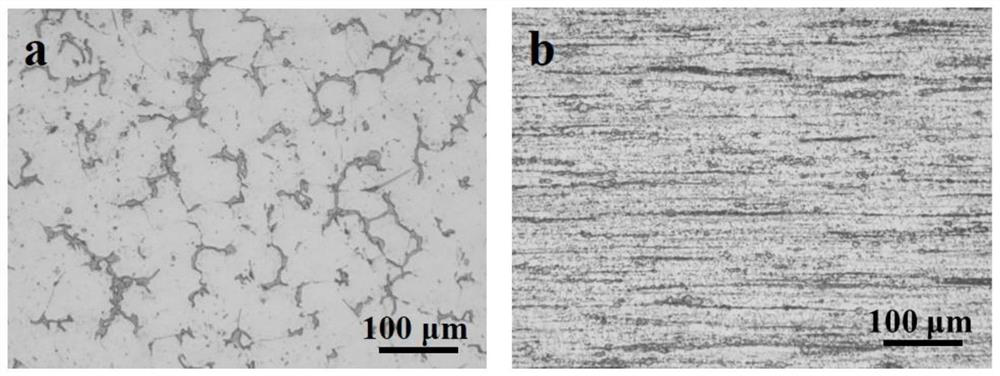

Image

Examples

preparation example Construction

[0038] According to the composition characteristics of alloying elements of the Mg-Gd-Y-Nd high-strength and tough rare earth magnesium alloy of the present invention, a targeted casting and molding preparation method is provided to obtain optimal mechanical properties and microstructure morphology, and The lowest elemental depletion rate, including the following steps:

[0039] Step 1. Preparation of Magnesium Alloy Ingot

[0040] Using pure Mg, pure Zn, pure Ag, Mg-Zr master alloy, Mg-Gd master alloy, Mg-Y master alloy, Mg-Nd master alloy, Mg-Sc master alloy as raw materials, according to Mg-Gd-Y-Nd high strength The mass percentage of each element of the ductile rare earth magnesium alloy is batched, smelted to obtain alloy liquid, cast and formed, and a casting is obtained;

[0041] Step 2, solid solution treatment

[0042] Heat-treat the casting at 500-520°C for 6-12 hours, then air-cool to room temperature to obtain the casting after solution treatment;

[0043] Step ...

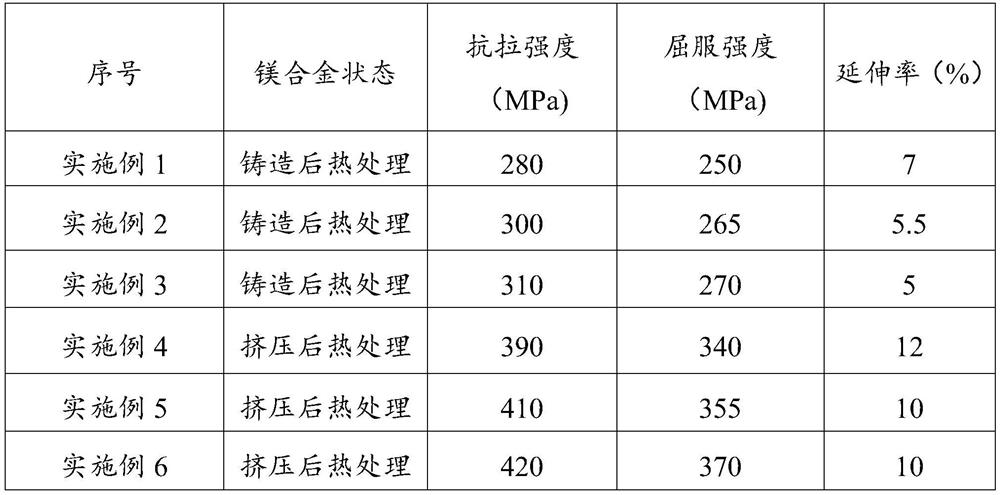

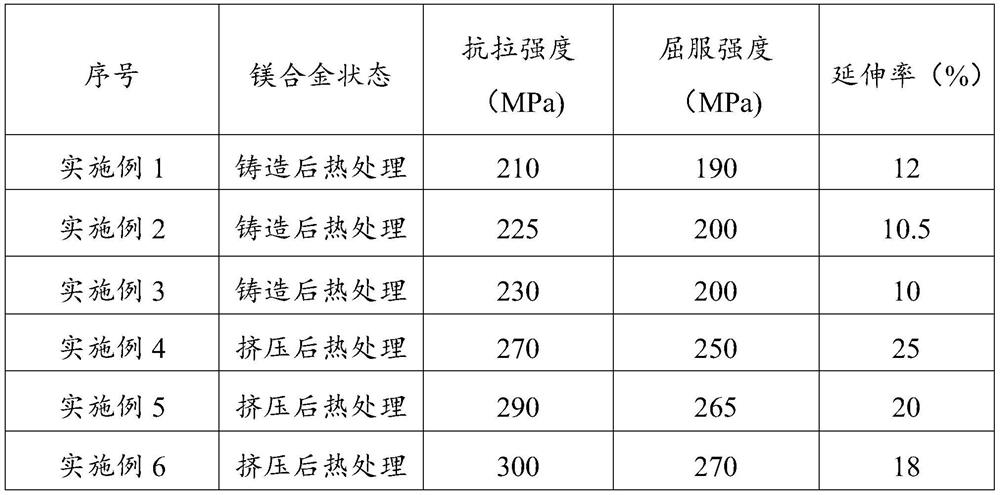

Embodiment 1

[0062] Mg-Gd-Y-Nd high strength and toughness rare earth magnesium alloy: Gd: 6.5wt.%, Y: 1.5wt.%, Nd: 1.5wt.%, Ag: 0.5wt.%, Sc: 0.05wt.%, Zr: 0.45wt.%, Zn: 0.2wt.%, the balance is Mg and unavoidable impurities.

[0063] The preparation method of the above-mentioned Mg-Gd-Y-Nd high strength and toughness rare earth magnesium alloy:

[0064] Step 1, according to the mass percentage of each element of the Mg-Gd-Y-Nd high strength and toughness rare earth magnesium alloy, weigh pure Mg, pure Zn, pure Ag, Mg-Zr master alloy, Mg-Gd master alloy (20 ~ 30wt. %), Mg-Y master alloy (20~30wt.%), Mg-Nd master alloy (20~30wt.%) and Mg-Sc master alloy (1~3wt.%), cleaning, drying, smelting, and Preheat to 300°C;

[0065] in CO 2 and SF 6 Under the protection of mixed gas (volume ratio: 99.8:0.2), pure Mg, pure Zn, pure Ag, Mg-Gd master alloy (20~30wt.%), Mg-Y master alloy (20~30wt.%) And Mg-Nd master alloy (20~30wt.%) is heated to 680~750°C until completely melted, and then the melt is...

Embodiment 2

[0069] Mg-Gd-Y-Nd high strength and toughness rare earth magnesium alloy: Gd: 8wt.%, Y: 2wt.%, Nd: 2wt.%, Ag: 0.4wt.%, Sc: 0.07wt.%, Zr: 0.45wt. %, Zn: 0.2wt.%, the balance is Mg and unavoidable impurities.

[0070] The preparation method is the same as that of Example 1, except that step 3 is replaced by: heat-treating the casting at 250° C. for 24 hours, and then air-cooling to room temperature to obtain a solution-treated casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com