High-ductility, high-strength electro-galvanized steel sheet and manufacturing method thereof

A manufacturing method and electro-galvanizing technology, applied in the direction of manufacturing tools, circuits, magnetic objects, etc., can solve the problems of not easy to release, reduced local ductility, implied ductility, etc., to suppress decarburization, excellent bendability, and reduce diffusivity Effect of Hydrogen Amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

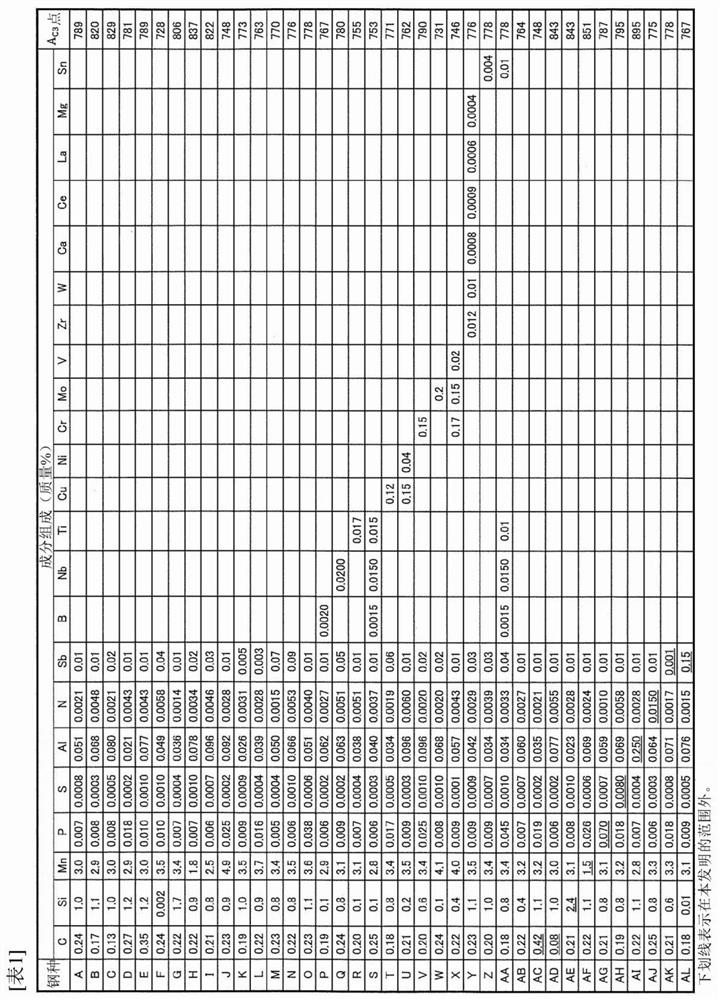

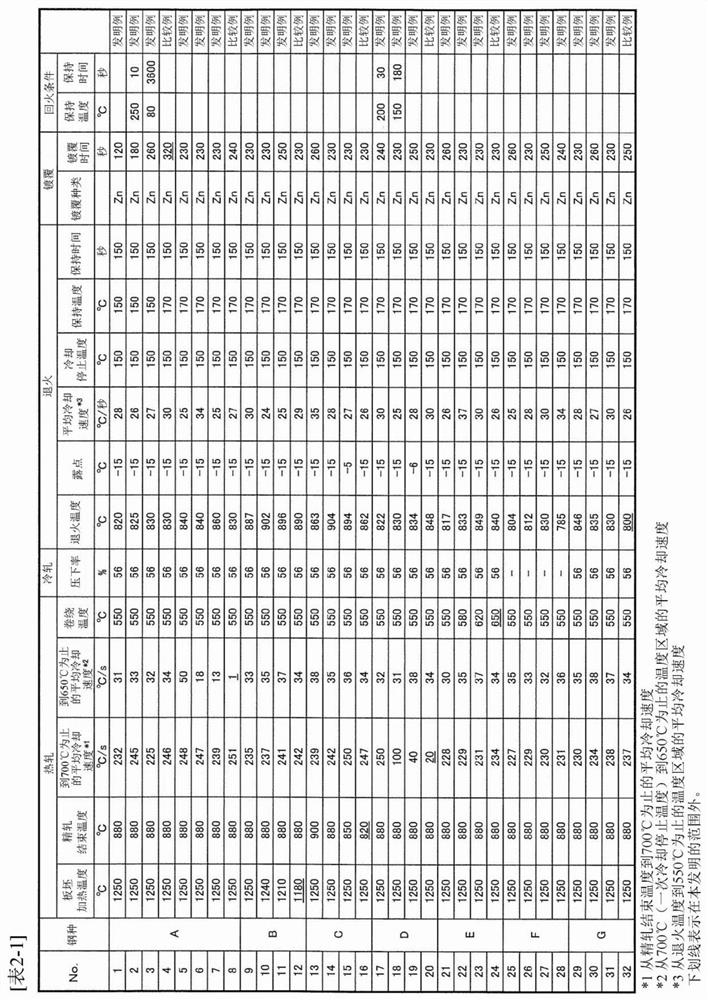

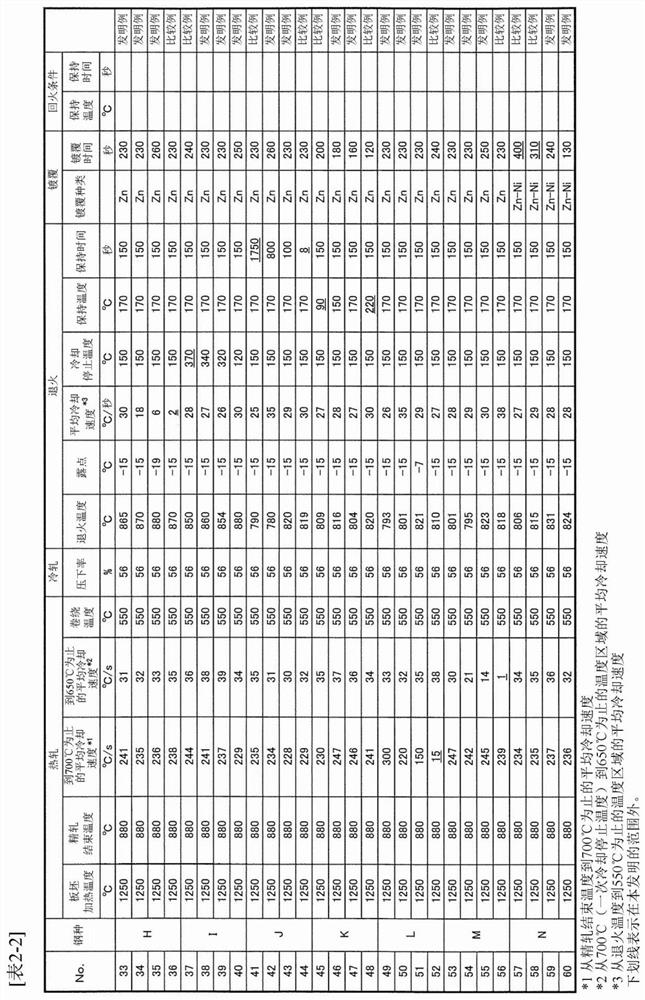

[0116] The present invention will be specifically described with reference to examples.

[0117] 1. Manufacture of steel plates for evaluation

[0118]The steel having the composition shown in Table 1 and the remainder consisting of Fe and unavoidable impurities was smelted in a vacuum melting furnace, followed by billet rolling to obtain a billet-rolled material with a thickness of 27 mm. The obtained billet-rolled material was hot-rolled to a plate thickness of 4.0 mm to produce a hot-rolled steel sheet (hot-rolling process). Next, for the cold-rolled sample, the hot-rolled steel sheet was ground to a thickness of 3.2 mm, and then cold-rolled at the reduction ratio shown in Table 2-1 to Table 2-4 to a thickness of 1.4 mm. , Manufacture cold rolled steel sheet (cold rolling process). In addition, in Table 2-1, when the numerical value of the reduction rate of cold rolling is not described, it means that cold rolling was not performed. Next, the hot-rolled steel sheets and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com