Steel wire rod for bridge cables and manufacturing method thereof

A manufacturing method and steel wire rod technology, which is applied in the field of manufacturing steel wire rods for bridge cables and steel wire rods for bridge cables, can solve problems such as high cost and long process flow, achieve good carbon segregation, and improve central equiaxial Crystal, the effect of ensuring castability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

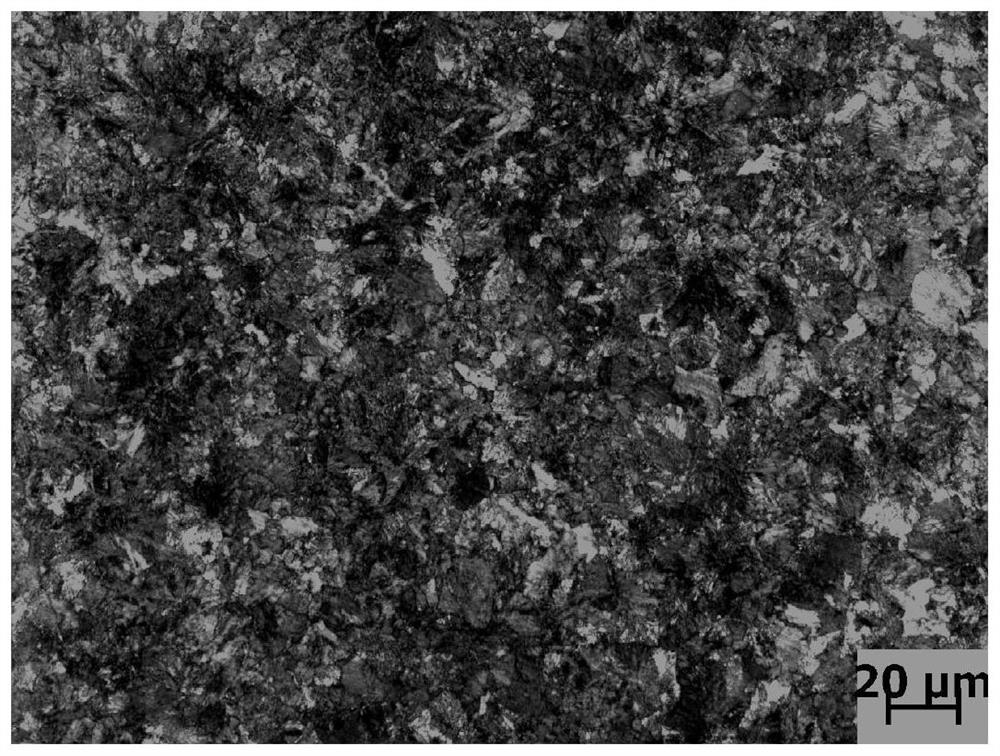

Image

Examples

Embodiment 1

[0023] The composition of steel wire rod for bridge cable of embodiment 1 is C: 0.85%, Si: 0.35%, Mn: 0.70%, Cr: 0.10%, P: 0.010%, S: 0.010%, Ni: 0.10%, Cu: 0.05%, Al: 0.04%, V: 0.05%, O: 0.002%, N: 0.004%, and the balance is iron and unavoidable impurities.

[0024] In this embodiment, the mechanical properties of the steel wire rod for cables without heat treatment are ensured, the heat treatment process is reduced, and the production cost is saved by properly proportioning Cr, V, Al, and Si elements in the composition. Among them, the element Cr0.10% can ensure the strength of the steel wire through the test, and can inhibit decarburization to a certain extent. Because if it is too high or too low, the plasticity index of the wire rod will be reduced, and the control of the sorbite structure is difficult. The choice of element V0.05% is confirmed in the course of the test, and the presence of this proportion of V in the form of carbonitride in the steel can effectively imp...

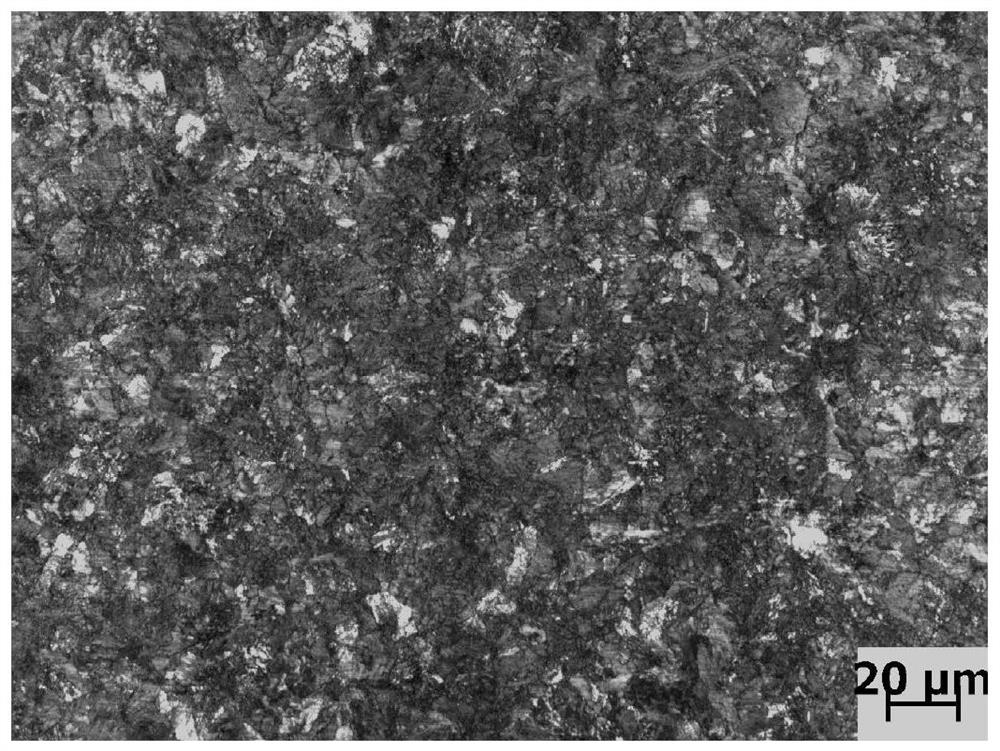

Embodiment 2

[0033] As in the preparation steps of Example 1, the chemical composition of the steel wire rod for bridge cables in Example 2 is C: 0.88%, Si: 0.25%, Mn: 0.80%, Cr: 0.20%, P: 0.005% in weight percentage , S: 0.005%, Ni: 0.20%, Cu: 0.02%, Al: 0.030%, V: 0.03%, O: 0.001%, N: 0.002%, and the balance is iron and unavoidable impurities.

[0034] Tundish superheat control after VD vacuum treatment: 20°C; mold electromagnetic stirring current 400A, frequency 3.5HZ; terminal electromagnetic stirring current 500A, frequency 10HZ; continuous casting billet size 150mm×150mm.

[0035] During the rolling process, the billet heating parameters are as follows: heating stage 1 830°C, heating stage 2 1050°C, soaking stage 1120°C; total heating time 120min; hot rolling parameters: starting rolling temperature 1030°C, entering finishing mill 900°C, The reduced warp is 900°C, the silk spinning is 900°C; the speed of the roller table is 1.2m / s, and the speed of the finished product is 30m / s; the ...

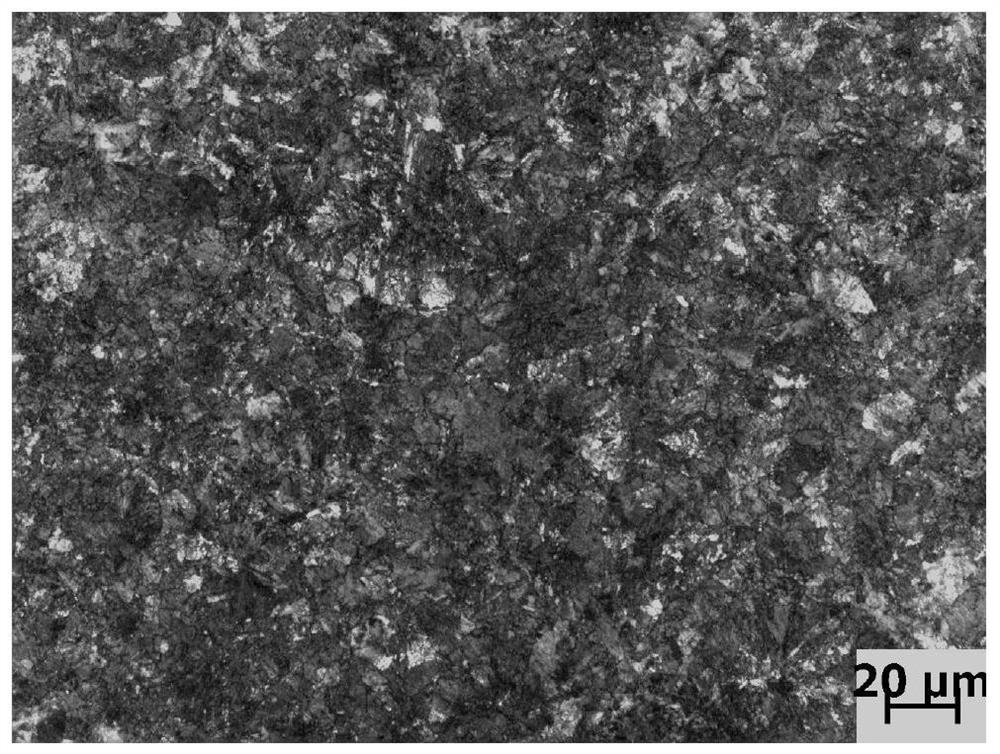

Embodiment 3

[0038] As in the preparation steps of Example 1, the chemical composition of the steel wire rod for bridge cables in Example 3 is C: 90%, Si: 0.50%, Mn: 0.90%, Cr: 0.10%, P: 0.010% in weight percentage , S: 0.007%, Ni: 0.15%, Cu: 0.05%, Al: 0.03%, V: 0.05%, O: 0.002%, N: 0.004%, and the balance is iron and unavoidable impurities.

[0039] After VD vacuum treatment, the superheat of the tundish is controlled at 25°C; the electromagnetic stirring current of the mold is 400A, the frequency is 3.5HZ; the terminal electromagnetic stirring current is 500A, and the frequency is 10HZ; the specification of the continuous casting billet is 150mm×150mm.

[0040] During the rolling process, the heating parameters of the billet are: heating stage 1 860°C, heating stage 2 1125°C, soaking stage 1160°C; total heating time 150min; The reduced warp is 930°C, the silk spinning is 930°C; the speed of the roller table is 1.2m / s, and the speed of the finished product is 20m / s; the air cooling param...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com