Aluminum-containing high-strength steel and preparation method and application of aluminum-containing high-strength steel

A technology of high-strength steel and chemical composition, applied in the field of steel rolling, which can solve problems such as chromatic aberration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 5

[0069] Embodiment 1 to embodiment 5 provide a kind of aluminum-containing high-strength steel and its preparation method and application. The preparation method is as follows:

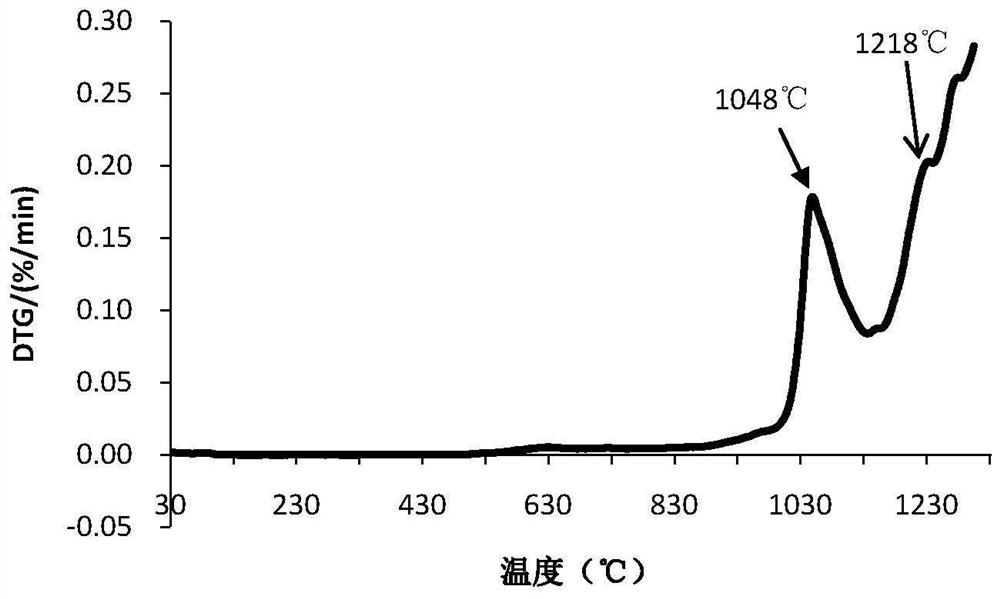

[0070] The slab obtained by continuous casting is placed in a heating furnace for heating. During heating, the temperature of the first stage of heating is 700-800°C, the temperature of the second stage of heating is 1150-1190°C, the temperature of the soaking section is 1190-1220°C, and the total heating time is 130-160 minutes, followed by two passes of rough rolling and finish rolling for descaling, finish rolling, ultra-fast cooling and coiling to obtain hot-rolled coils. Among them, the pressure of descaling water in the two passes of finishing rolling is 23MPa, and the ultra-fast cooling adopts laminar flow cooling front-end cooling mode,

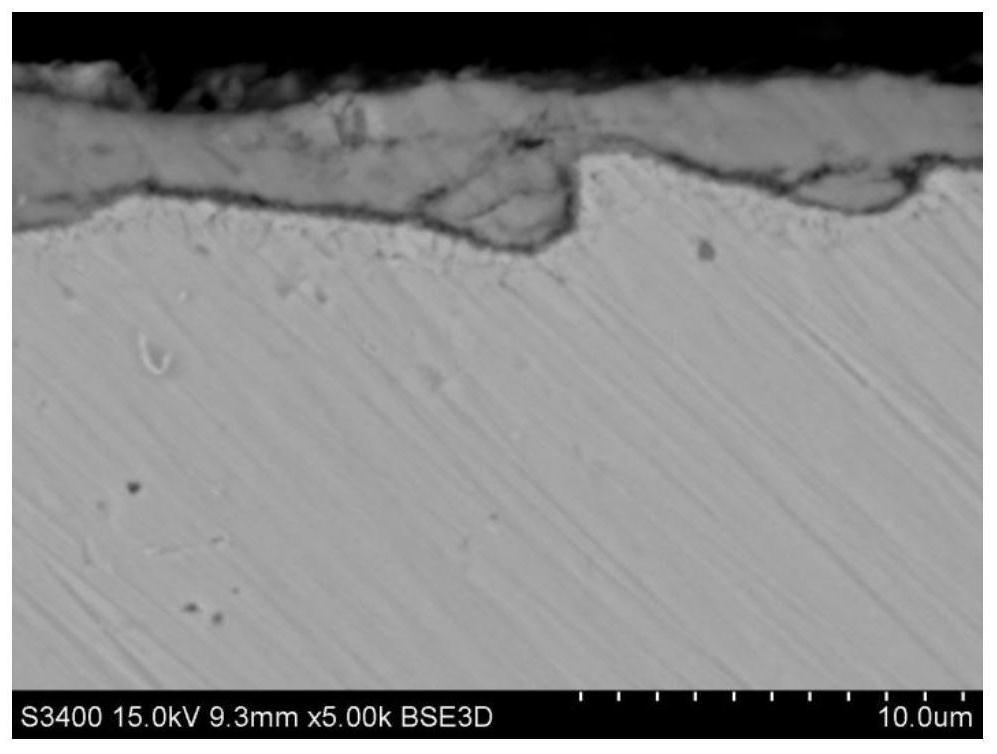

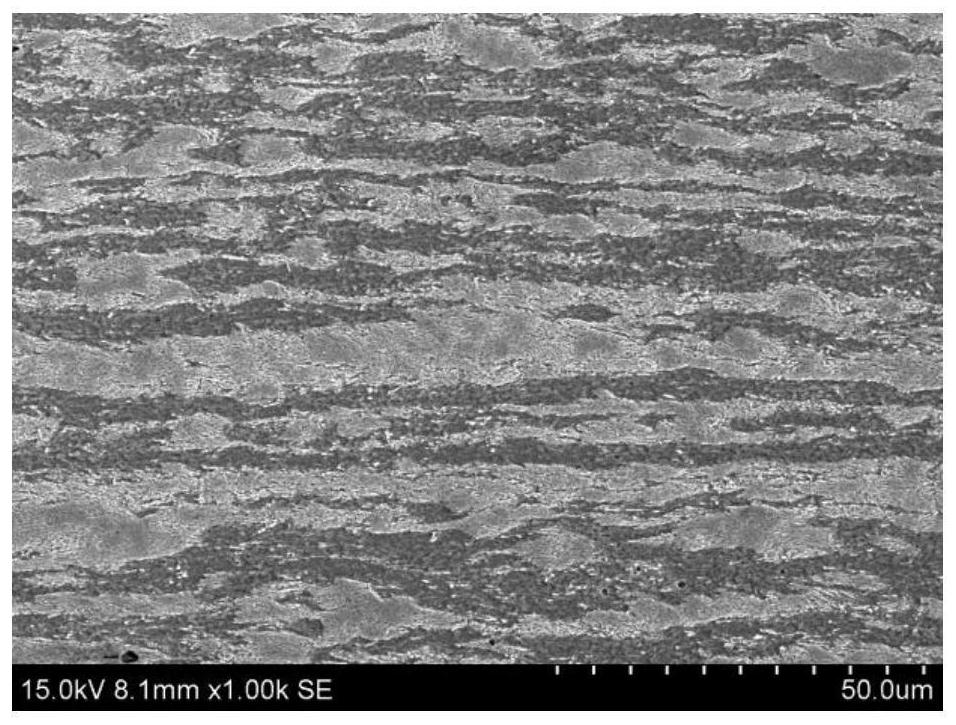

[0071] Hot-rolled coils are pickled and cold-rolled, followed by continuous annealing to obtain high-strength steel. The cold rolling is 5 passes of continuo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com