Spring steel with good heat resistance and impact resistance and production method thereof

A production method and impact-resistant technology, applied in the field of spring steel production, can solve the problems of poor performance of spring steel, difficult to meet, poor tensile strength, impact resistance and hydrogen embrittlement fracture resistance, etc., to ensure strength, toughness and durability Effect of hydrogen embrittlement fracture performance, improvement of strength and toughness, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

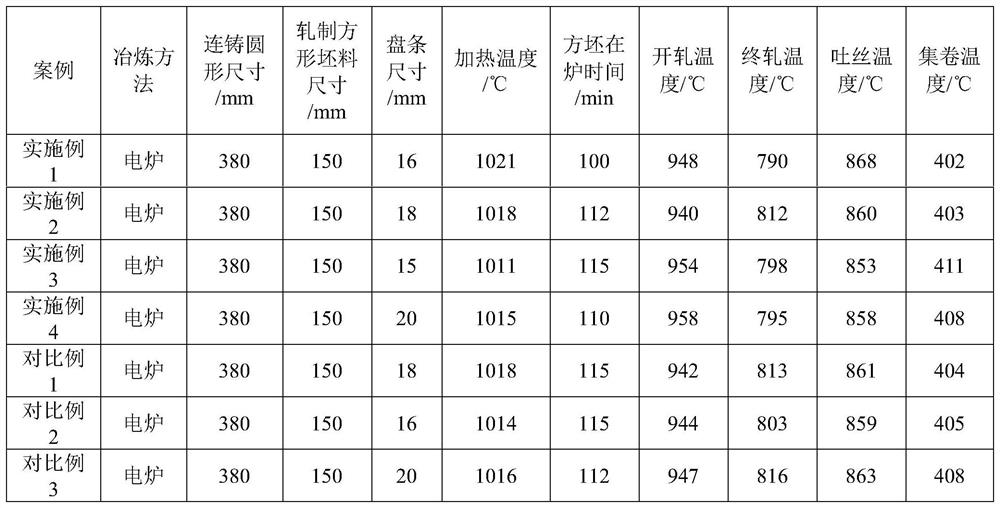

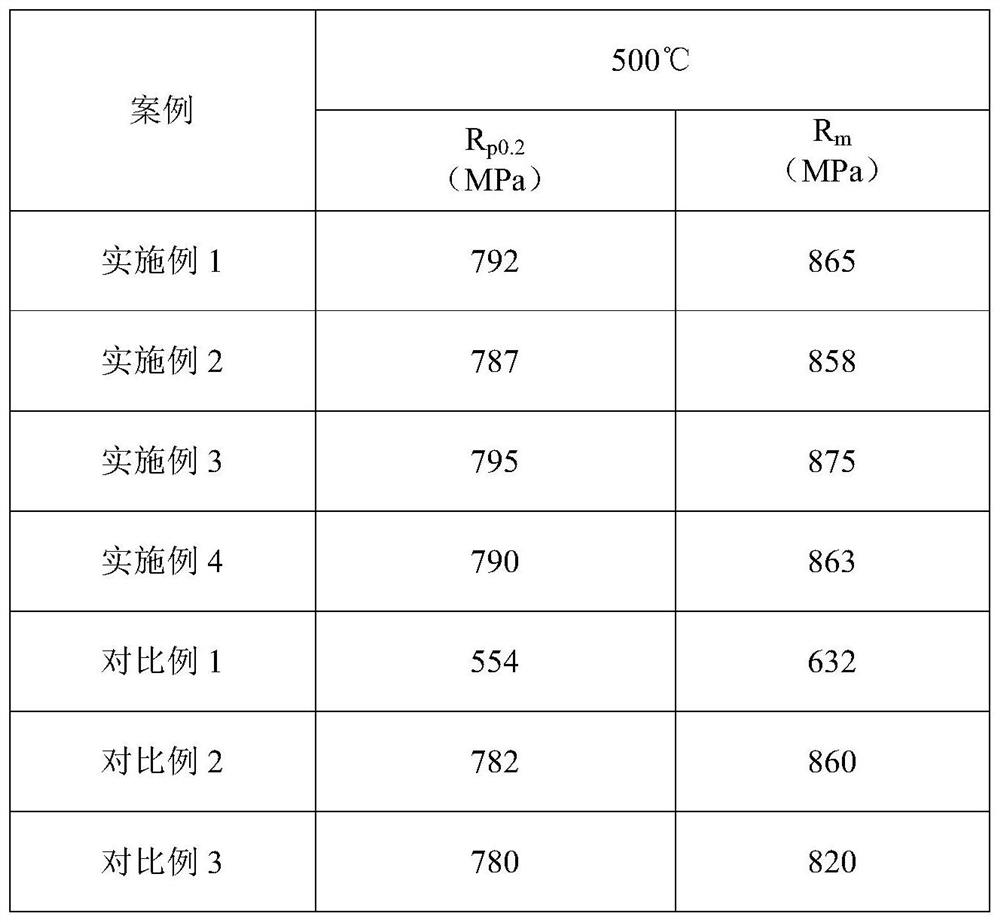

[0063]The chemical composition of the spring steel of this embodiment is: C: 0.50%, Si: 1.60%, Mn: 0.80%, Cr: 0.80%, Mo: 0.4%, W: 0.70%, V: 0.20%, Nb: 0.02 %, Ti: 0.015%, Ni: 0.20%, Cu: 0.20%, P: 0.015%, S: 0.010%, O: 0.0012%, N: 0.006%, and the rest are Fe and other unavoidable impurities. Wherein, P value = 1.75, Meq value = 0.312.

[0064] Its processing step adopts the technical process of the present invention, and the control parameters of its wire rod rolling related technical process are as follows: figure 1 Shown, and then its normal temperature mechanical properties, high temperature mechanical properties, hydrogen embrittlement resistance were tested, the results are shown in figure 2 , image 3 and Figure 4 .

Embodiment 2

[0066] The chemical composition of the spring steel of this embodiment is: C: 0.60%, Si: 2.00%, Mn: 1.00%, Cr: 1.30%, Mo: 0.50%, W: 1.30%, V: 0.40%, Nb: 0.04 %, Ti: 0.030%, Ni: 0.15%, Cu: 0.15%, P: 0.015%, S: 0.010%, O: 0.0012%, N: 0.006%, and the rest are Fe and other unavoidable impurities. Wherein, P value = 2.6, Meq value = 0.282.

[0067] Its processing step adopts the technical process of the present invention, and the control parameters of its wire rod rolling related technical process are as follows: figure 1 Shown, and then its normal temperature mechanical properties, high temperature mechanical properties, hydrogen embrittlement resistance were tested, the results are shown in figure 2 , image 3 and Figure 4 .

Embodiment 3

[0069] The chemical composition of the spring steel of this embodiment is: C: 0.56%, Si: 2.20%, Mn: 0.90%, Cr: 1.00%, Mo: 0.20%, W: 0.80%, V: 0.30%, Nb: 0.02 %, Ti: 0.020%, Ni: 0.30%, Cu: 0.30%, P: 0.015%, S: 0.009%, O: 0.0011%, N: 0.003%, and the rest are Fe and other unavoidable impurities. Wherein, P value = 4.0, Meq value = 0.343.

[0070] Its processing step adopts the technical process of the present invention, and the control parameters of its wire rod rolling related technical process are as follows: figure 1 Shown, and then its normal temperature mechanical properties, high temperature mechanical properties, hydrogen embrittlement resistance were tested, the results are shown in figure 2 , image 3 and Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fatigue strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com