Heat treatment process of brazing tool steel XGQ25 with gradient hardness distribution

A technology of hardness gradient and drilling tool steel, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem that it is difficult to obtain the external strength and internal toughness of the drilling tool, the short life of the drilling tool, and the inability to realize the surface of the drilling tool. and other issues to achieve good matching, improve service life, and avoid phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

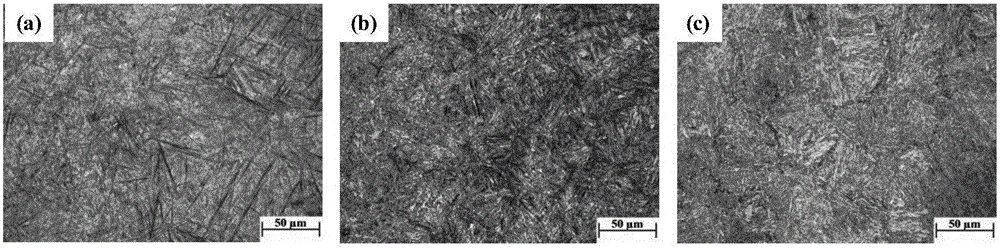

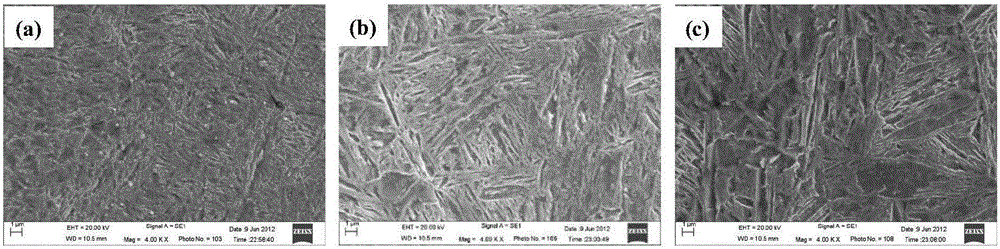

Image

Examples

Embodiment 1

[0019] Hot-rolled XGQ25 steel bar (chemical composition is C: 0.24-0.26%, Si: 1.62-1.72%, Mn: 1.45-1.55%, Cr: 0.32-0.38%, Ni: 1.46-1.55%, Mo: 0.63-0.68 %, V:0.10-0.12%, P:≤0.015%, S:≤0.008%) for rough machining, after the rough machining is completed, perform the following operations:

[0020] Step 1: Carburizing process: The drilling tools are made of hot-rolled XGQ25 steel rods, placed in a multifunctional carburizing furnace at 930°C for carburizing, the carburizing agent is kerosene, and the carburizing process is carried out in two stages: the carbon potential is controlled to 1.2 % when carburizing for 3 hours; then adjust the carbon potential to 1.0% and hold for 3 hours; after carburizing, cool to 850°C with the furnace, hold for 30 minutes, and oil quench to room temperature;

[0021] Step 2: Temper the drill tool after carburizing in the above steps at a high temperature of 650°C, keep it warm for 60 minutes, air-cool, and then finish machining according to the size ...

Embodiment 2

[0024] Hot-rolled XGQ25 steel bar (chemical composition is C: 0.24-0.26%, Si: 1.62-1.72%, Mn: 1.45-1.55%, Cr: 0.32-0.38%, Ni: 1.46-1.55%, Mo: 0.63-0.68 %, V:0.10-0.12%, P:≤0.015%, S:≤0.008%) for rough machining, after the rough machining is completed, perform the following operations:

[0025] Step 1: Carburizing process: The drilling tools are made of hot-rolled XGQ25 steel rods, placed in a multifunctional carburizing furnace at 940°C for carburizing, the carburizing agent is kerosene, and the carburizing process is carried out in two stages: the carbon potential is controlled to 1.2 % when carburizing for 3 hours; then adjust the carbon potential to 1.0% and hold for 3 hours; after carburizing, cool to 850°C with the furnace, hold for 30 minutes, and oil quench to room temperature;

[0026] Step 2: Temper the drill tool after carburizing in the above steps at a high temperature of 650°C, keep it warm for 60 minutes, air-cool, and then finish machining according to the size ...

Embodiment 3

[0029] Hot-rolled XGQ25 steel bar (chemical composition is C: 0.24-0.26%, Si: 1.62-1.72%, Mn: 1.45-1.55%, Cr: 0.32-0.38%, Ni: 1.46-1.55%, Mo: 0.63-0.68 %, V:0.10-0.12%, P:≤0.015%, S:≤0.008%) for rough machining, after the rough machining is completed, perform the following operations:

[0030] Step 1: Carburizing process: The drilling tools are made of hot-rolled XGQ25 steel rods, placed in a multifunctional carburizing furnace at 930°C for carburizing, the carburizing agent is kerosene, and the carburizing process is carried out in two stages: the carbon potential is controlled to 1.2 % when carburizing for 3 hours; then adjust the carbon potential to 1.0% and hold for 3 hours; after carburizing, cool to 850°C with the furnace, hold for 30 minutes, and oil quench to room temperature;

[0031] Step 2: Temper the drill tool after carburizing in the above steps at a high temperature of 650°C, keep it warm for 60 minutes, air-cool, and then finish machining according to the size ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com