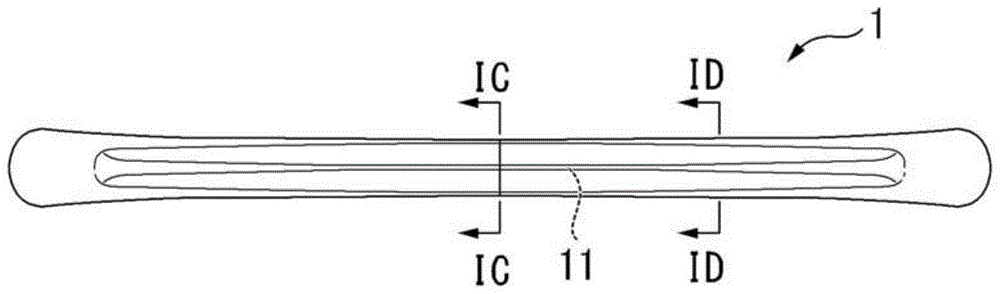

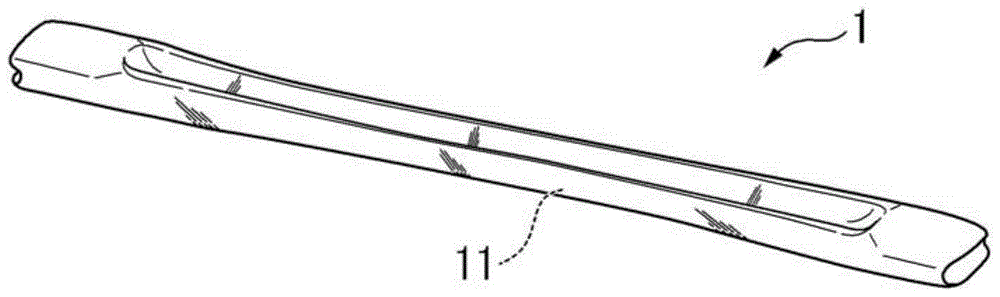

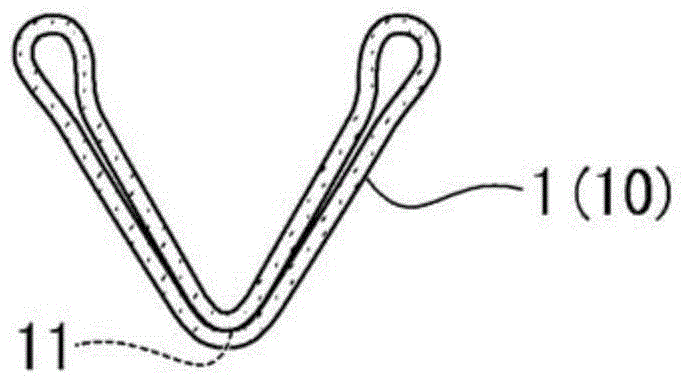

Quenched steel pipe member, automobile axle beam using the quenched steel pipe member, and method for manufacturing the quenched steel pipe member

A manufacturing method and component technology, which can be applied to coatings, metal material coating processes, hot dip plating processes, etc., can solve problems such as large cost, cost, zinc volatilization, etc., so as to inhibit decarburization, improve fatigue characteristics, and inhibit fatigue. The effect of reducing the lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0130] Examples are shown below.

[0131] As inventive examples 1 to 6 and comparative examples 1 to 3, GI steel sheets with a composition of 0.24%C-0.2%Si-1.2%Mn-0.02%Ti-10ppmB were welded by electric welding, followed by press working, electrical heating and spray cooling , thereby manufacturing the shaft beam, and measured the micro-Vickers hardness at a depth of 50 μm from the surface of the base metal, the micro-Vickers hardness at a depth of 200 μm from the surface of the base metal, and fatigue properties. In addition, in Inventive Examples 1 to 6 and Comparative Examples 1 and 2, the contact portions were integrated by alloying.

[0132] Table 1 shows various setting conditions and measurement results. A is the weight per unit area (g / m 2 ), T is the highest heating temperature (°C), t is the holding time (hours), B is the heat treatment parameter, X is the micro-Vickers hardness at a depth of 200 μm from the surface of the base metal, and Y is the depth of 50 μm fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com