Steel for single-layer concrete conveying pipe of trailer pump vehicle and production method thereof

A production method and concrete technology, which is applied in the field of low-alloy steel manufacturing, can solve problems affecting the yield and performance of steel plates, poor steel plate forming and processing performance, poor pearlite spheroidization rate, etc., to achieve stable and refined pearlite , Improve hardenability, hinder the effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the examples to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

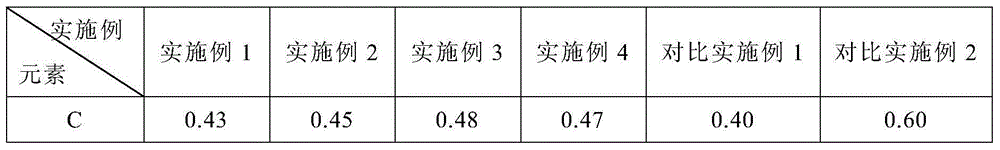

[0041] According to the chemical element composition, weight percentage and production method requirements of the present invention, prepared four embodiments, and two comparative examples, respectively embodiment 1, embodiment 2, embodiment 3, embodiment 4, comparative example 1 , Comparative Example 2, that is, 6 batches of steel were smelted and rolled. See Table 1, Table 2 and Table 3 for the weight percentages of chemical elements, process parameters and test results of the four embodiments and two comparative examples.

[0042] Table 1 The chemical composition comparison (wt, %) of four embodiments and two comparative examples

[0043]

[0044]

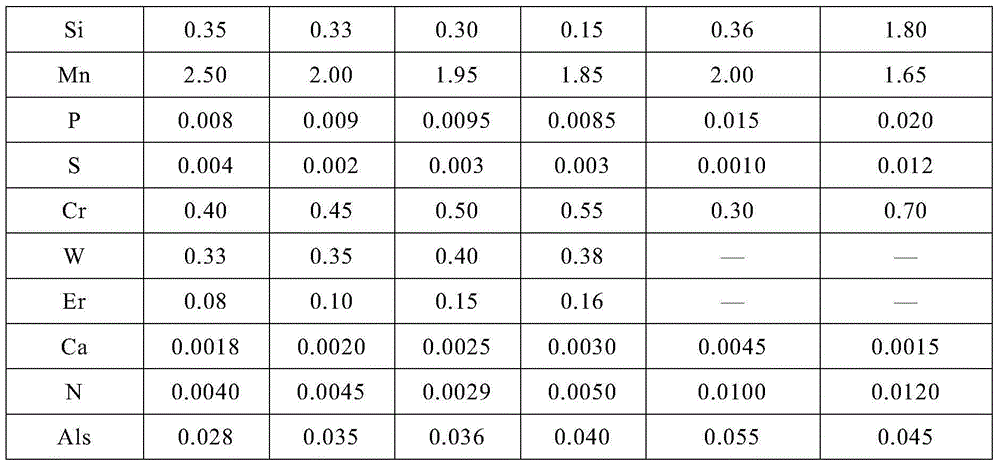

[0045] Table 2 The comparison of main process parameters of four embodiments and two comparative examples

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com