Long-fatigue-life strip steel as well as preparation method and application thereof

A technology for fatigue life and strip steel, applied in the field of high fatigue life strip steel and its preparation, which can solve the problems of decarburization, reducing the fatigue performance of products, and restricting the use of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

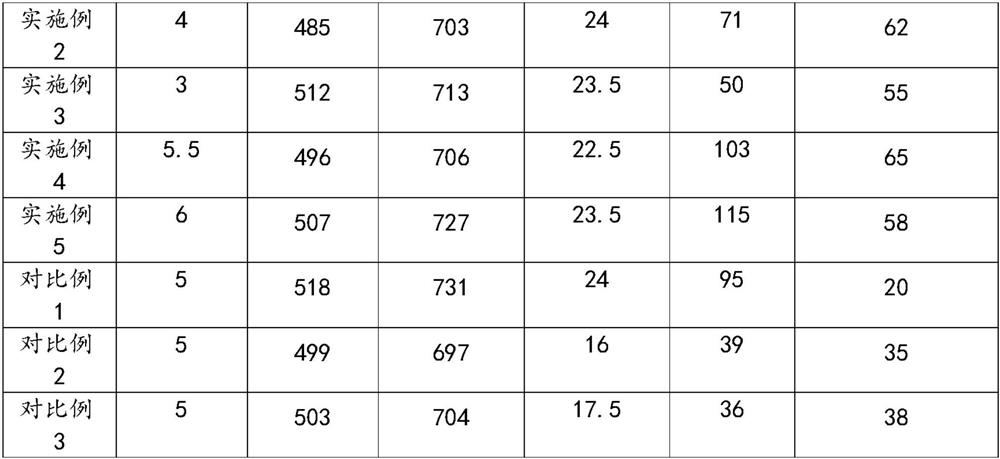

Examples

preparation example Construction

[0043] According to another typical embodiment of the present invention, a method for preparing strip steel with high fatigue life is also provided, the method comprising:

[0044] obtaining a cast slab of said high fatigue life steel strip;

[0045] Heating the cast slab before rolling, hot rolling, cooling after rolling and coiling to obtain hot rolled coils;

[0046] In the heating before piercing, the temperature out of the furnace is 1180-1260°C, and the time in the furnace is ≥180min,

[0047] The hot rolling includes rough rolling and finish rolling, the termination temperature of the rough rolling is 1020-1100°C, and the termination temperature of the finish rolling is 840-880°C,

[0048] In the post-rolling cooling, intensive cooling to 580-640°C is adopted in the front stage.

[0049] In the heating before rolling, the furnace temperature is controlled to be 1180-1260 ° C, and the reason for the furnace time ≥ 180 min is to fully melt the alloying elements. If the...

Embodiment 1

[0055] The high-fatigue-life steel strip provided in this embodiment is composed of the following chemical components in mass fraction:

[0056] C 0.28%, Si 0.15%, Mn 1.3%, P 0.014%, S 0.002%, Al 0.04%, Ti 0.02%, B 0.0030%, Cr 0.25%, N 0.004%, Sb: 0.08%, Sn: 0.1% , and the rest are Fe and unavoidable impurities.

[0057] This embodiment also provides a preparation method for the above-mentioned strip steel with high fatigue life, including:

[0058] obtaining a cast slab of said high fatigue life steel strip;

[0059] Heating the cast slab before rolling, hot rolling, cooling after rolling and coiling to obtain hot rolled coils;

[0060] In the pre-stripping heating, the furnace temperature is 1240°C, the time in the furnace is 220min, the length, width and height of the billet are controlled to be 8.5m, 1m and 230mm respectively, and the temperature difference of the cross section of the billet is controlled to be 12°C;

[0061] Hot rolling includes rough rolling and finis...

Embodiment 2

[0065] The high-fatigue-life steel strip provided in this embodiment is composed of the following chemical components in mass fraction:

[0066] C 0.36%, Si 0.18%, Mn 1.2%, P 0.013%, S 0.002%, Al 0.05%, Ti 0.03%, B0.0025%, Cr 0.2%, N 0.003%, Sb: 0.15%, the rest is Fe and unavoidable impurities.

[0067] This embodiment also provides a preparation method for the above-mentioned strip steel with high fatigue life, including:

[0068] obtaining a cast slab of said high fatigue life steel strip;

[0069] Heating the cast slab before rolling, hot rolling, cooling after rolling and coiling to obtain hot rolled coils;

[0070] In the pre-stripping heating, the furnace temperature is 1220°C, the time in the furnace is 230min, the length, width and height of the billet are controlled to be 9m, 900mm and 230m respectively, and the temperature difference of the cross section of the billet is controlled to be 15°C;

[0071] Hot rolling includes rough rolling and finish rolling. In roug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com