Method for evaluating coating stress of thermally induced phase change film regulation

A technology of thermally induced phase change and coating, which is applied in the evaluation of tool coating stress and the evaluation field of thermally induced phase change film regulating tool coating stress, which can solve the problems of lack of evaluation methods, improvement, and impact on tool quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawings and examples.

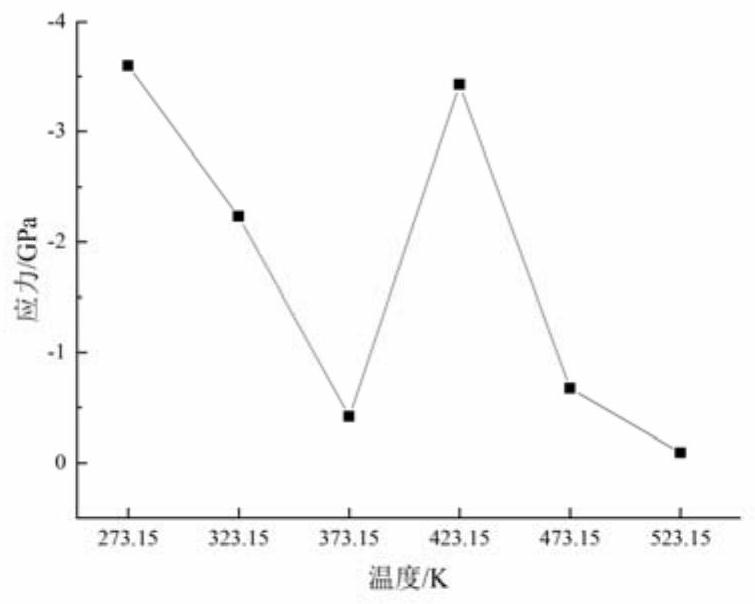

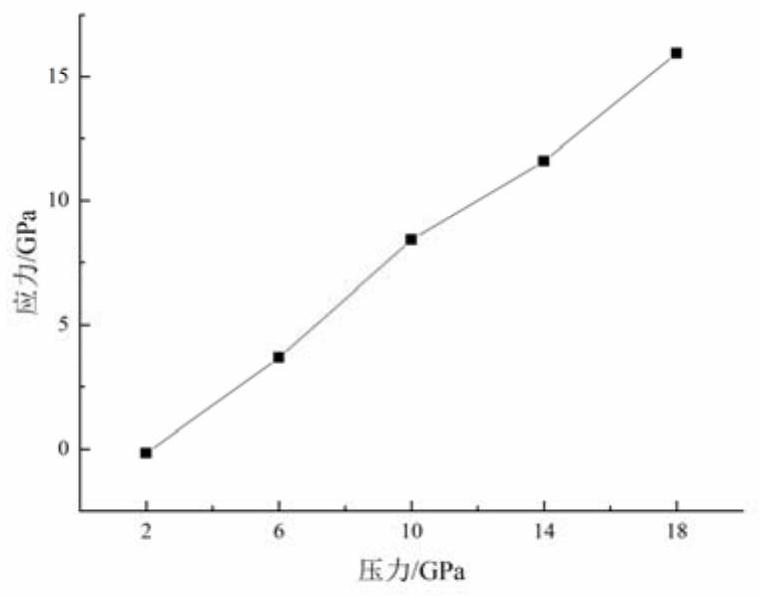

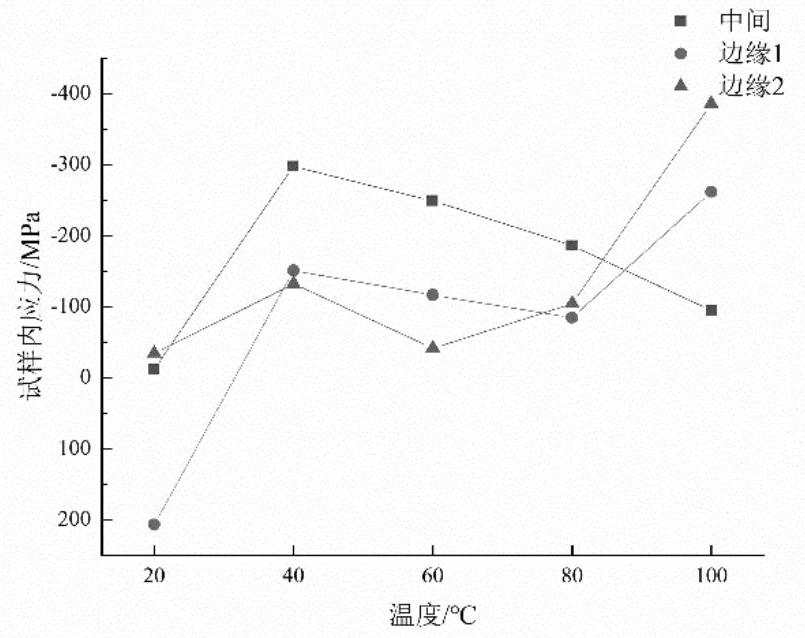

[0025] Such as Figure 1-3 shown.

[0026] An evaluation method for regulating the stress of a tool coating by a thermally induced phase change film, comprising the following steps:

[0027] (1) For M-phase VO 2 Crystal plane of unit cell and supercell of diamond crystal plane;

[0028] The relevant parameters of the supercellular process are determined by the following steps,

[0029] (1) Construct M-phase VO 2 Unit cell and diamond unit cell, and geometry optimization, M-phase VO 2 The unit cell parameters for unit cell optimization are unit cell lengths a, b, c, β and volume V, and the absolute value of the error between the optimization results and the experimentally measured values does not exceed 2%; the unit cell parameters for diamond unit cell optimization are unit cell length a , b, c and volume V, the absolute value of the error between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com