Gradient transition layer for improving film-substrate bonding strength of high-entropy nitride film and preparation method

A nitride film, gradient transition technology, applied in coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of poor film-base bonding force, affecting the service life of the tool, etc., to alleviate the internal stress of the film, The effect of improving the service life and improving the bonding strength of the membrane base

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

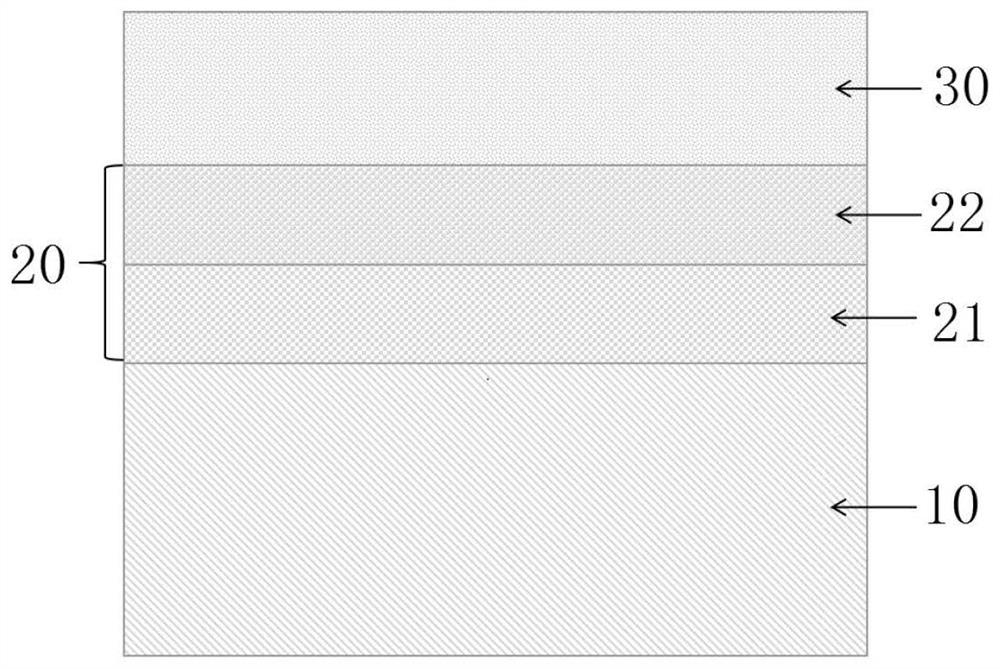

[0032] The invention discloses a preparation method of a gradient transition layer for improving the bonding strength of a high-entropy nitride film and a film base. A metal layer is deposited on the tool substrate; wherein the metal layer contains at least one metal element in the tool substrate; a metal nitride connection layer is deposited on the metal layer; wherein the metal nitride connection layer includes at least one of the nitride thin film layers A constituent element, and the constituent element is not N element; a nitride thin film layer is deposited on the metal nitride tie layer.

[0033] In the present invention, the metal layer and the metal nitride connection layer are sequentially deposited by the magnetron sputtering method between the tool base and the nitride film layer, and the components in the metal nitride connection layer change continuously, so that the internal stress of the film can be alleviated, The bonding strength of the film base between the ...

Embodiment 1

[0042] In this embodiment, a high-speed steel tool matrix is selected, and the tool matrix contains Cr, and the gradient transition layer is composed of an AlSiTiVNbCr layer and a (AlSiTiVNbCr)N metal nitride connection layer. The specific preparation method is as follows:

[0043] (1) Sample pretreatment: put the high-speed steel tool into acetone for ultrasonic cleaning for 5 minutes, then ultrasonically clean it with deionized water for 2 times, each cleaning for 3 minutes, and finally put it into anhydrous ethanol for ultrasonic cleaning for 2 times, each cleaning for 3 minutes , blow dry for use.

[0044] (2) Preparation of thin film deposition: The cleaned high-speed steel tool is sent into a vacuum chamber equipped with an AlSiTiVNbCr target, the target is connected to a radio frequency power supply, and the target-base distance is 60mm; the vacuum is evacuated to 3×10 -3 After Pa, 60sccm of argon gas was introduced to keep the pressure in the vacuum chamber at about ...

Embodiment 2

[0051] In this embodiment, a high-speed steel tool matrix is selected, and the tool matrix contains Cr, and the gradient transition layer is composed of a metal Cr layer and a CrN layer. The specific preparation method is as follows:

[0052] (1) Sample pretreatment: put the high-speed steel tool into acetone for ultrasonic cleaning for 5 minutes, then ultrasonically clean it with deionized water for 2 times, each cleaning for 3 minutes, and finally put it in anhydrous ethanol for ultrasonic cleaning 2 times, each cleaning for 3 minutes , blow dry for use.

[0053] (2) Preparation of thin film deposition: The cleaned high-speed steel tool is sent into a vacuum chamber equipped with AlSiTiVNbCr target and Cr target, the AlSiTiVNbCr target is connected to the RF power supply, the Cr target is connected to the DC power supply, and the target base distance is 60mm; ×10 -3 After Pa, 60sccm of argon was introduced to keep the pressure in the vacuum chamber at about 0.74Pa, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com